Pressure quenching production method for annular workpiece

A technology for a ring-shaped workpiece and a production method, which is applied in the field of press-quenching production of ring-shaped workpieces, can solve the problems of the influence of the stability of the workpiece, many manual participation, and the workpiece is easily deformed, and achieves the effect of improving the qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

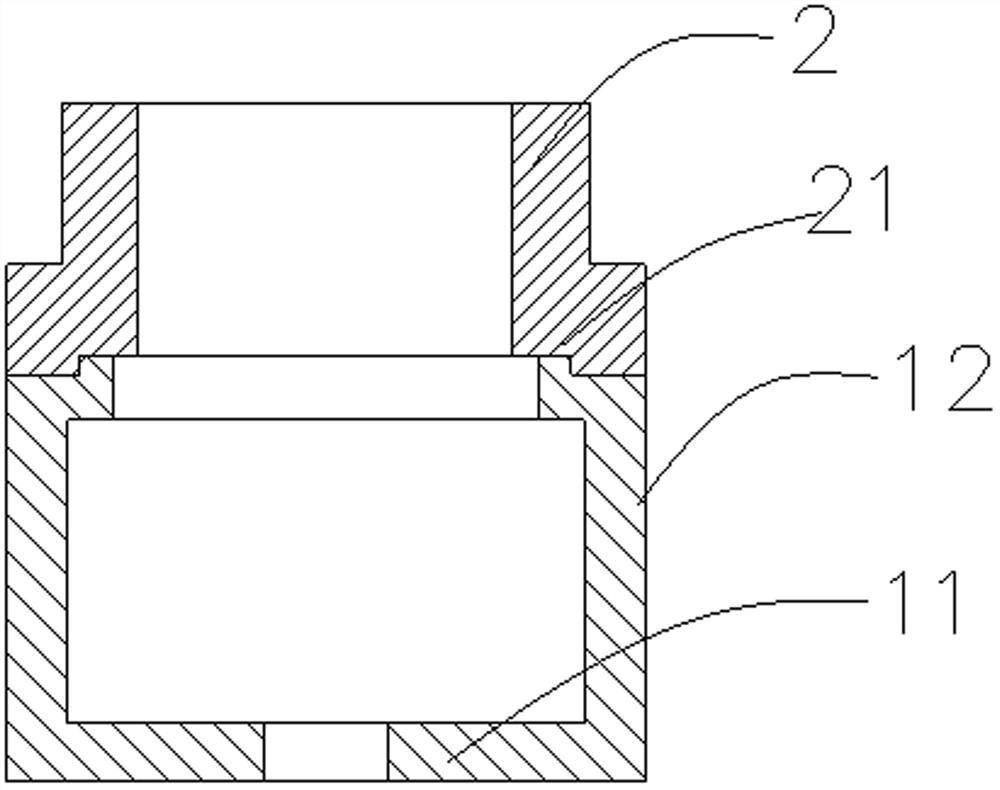

[0021] Such as figure 1 As shown, in the press-quenching production method of the ring-shaped workpiece disclosed in this embodiment, the ring-shaped workpiece is transported to the gear-aligning machine tool through the feeding machine tool, and the finger cylinder of the gear-aligning machine tool fixes the ring-shaped workpiece at the position of the gear-aligning station. On the disk, another cylinder two with a positioning switch moves the positioning switch to the tooth-aligning workpiece, and the workpiece rotates to the positioning switch to stop, completing the tooth alignment.

[0022] Transfer the ring-shaped workpiece after aligning the teeth to the heating machine tool. The heated workpiece rotation of the heating machine tool adopts frequency conversion speed regulation. The output end of the heater of the heating machine tool is connected to an inductor, and the sensor is aligned with the part that needs to be heated for induction heating. ;The heating workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com