Photo-curing matte surface-cleaning wood coating and preparation method thereof

A wood coating and photocuring technology, which is applied in the direction of polyester coating, polyurea/polyurethane coating, coating, etc., can solve the problem that the coating method of roller coating topcoat cannot be satisfied, and achieve good interlayer adhesion and low cost , Covering power and wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

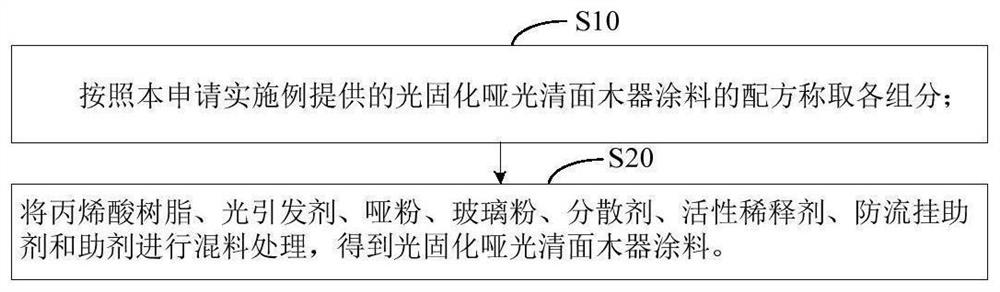

[0052] In a second aspect, the application provides a method for preparing a light-cured matte clear wood coating, comprising the following steps:

[0053] S10: Weigh each component according to the formula of light-curing matte clear wood coating provided in the embodiment of the present application;

[0054] S20: Mixing acrylic resin, photoinitiator, matte powder, glass powder, dispersant, reactive diluent, anti-sag additive and auxiliary agent to obtain light-cured matte clear wood coating.

[0055] In step S01, according to the light-cured matte clear wood coating of the embodiment of the present application, acrylic resin, photoinitiator, matte powder, wear-resistant powder, dispersant, reactive diluent, anti-sag additive, additive are provided, The selection type and the number of added parts of each component substance are as above, in order to save space, no more details are given here.

[0056] In step S02, acrylic resin, photoinitiator, dumb powder, wear-resistant pow...

Embodiment 1

[0060] This embodiment provides a light-cured matte clear wood coating and a preparation method thereof.

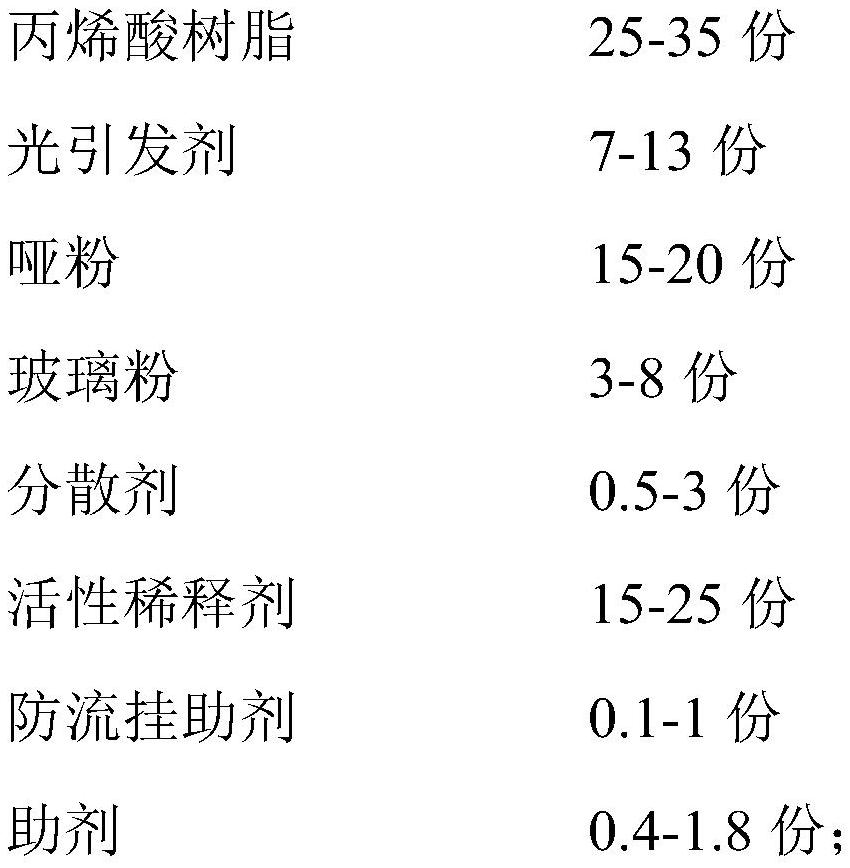

[0061] Light-curing matte clear wood coating, comprising the following components in the following parts by weight:

[0062]

[0063] Among them, the acrylic resin is selected from the mixture of nine-official aliphatic urethane acrylate resin and polyester acrylic resin with a mass ratio of 1:3; the photoinitiator is selected from the photoinitiator 2,4,6- Trimethylbenzoyl-diphenylphosphine oxide (TPO) and photoinitiator 2-isopropylthioxanthone (ITX);

[0064] The matte powder is selected from the mixture of Grace SYLOID Rad 2105 and SYLOID ED80 with a mass ratio of 14:3;

[0065] Glass powder is selected from Sibelco 925;

[0066] The dispersant is selected from BYK's dumb powder dispersant DISPERBYK 2009;

[0067] The active diluent is selected from the mixture of trimethylolpropane triacrylate (TMPTA) and dipropylene glycol diacrylate (DPGDA) with a mass ratio o...

Embodiment 2

[0076] This embodiment provides a light-cured matte clear wood coating and a preparation method thereof.

[0077] Light-curing matte clear wood coating, comprising the following components in the following parts by weight:

[0078]

[0079]

[0080] Wherein, the acrylic resin is selected from a mixture of nine-official aliphatic urethane acrylate resin and polyester acrylic resin with a mass ratio of 1:4.5;

[0081] The photoinitiator is selected from photoinitiator TPO and photoinitiator ITX with a mass ratio of 1:7;

[0082] The matte powder is selected from the mixture of Grace SYLOID Rad 2105 and SYLOID ED80 with a mass ratio of 14:3;

[0083] Glass powder is selected from Sibelco 925;

[0084] The dispersant is selected from BYK's dumb powder dispersant DISPERBYK 2009;

[0085] The active diluent is selected from the mixture of trimethylolpropane triacrylate (TMPTA) and dipropylene glycol diacrylate (DPGDA) with a mass ratio of 2:7;

[0086] The anti-sag additiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com