Biodegradable polyester resin composition with antistatic capability

A polyester resin, biodegradable technology, applied in the field of polyester resin, can solve the problems of environmental degradation, troublesome treatment, loss and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

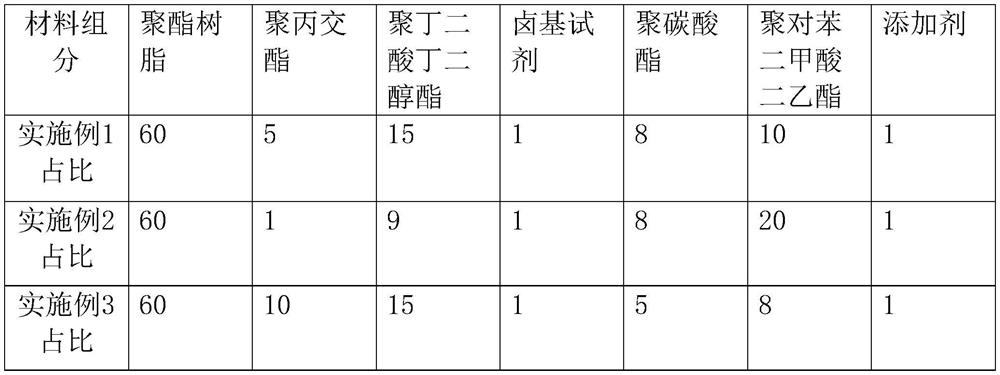

Embodiment 1

[0041] Embodiment 1: On the basis of percentage content 100%, wherein each raw material is polyester resin 60%, polylactide 5%, polybutylene succinate 15%, halogen reagent 1%, polycarbonate 8%, 8% polyethylene terephthalate, and 1% additive, the antistatic and biodegradable capabilities of the polyester resin composition are the same.

Embodiment 2

[0042] Embodiment 2: On the basis of percentage content 100%, wherein each raw material is polyester resin 60%, polylactide 1%, polybutylene succinate 9%, halogen reagent 1%, polycarbonate 8%, 20% polyethylene terephthalate, and 1% additive, the antistatic ability of the polyester resin composition is stronger, and it is more durable when its biodegradability becomes weaker.

Embodiment 3

[0043] Embodiment 3: On the basis of percentage content 100%, wherein each raw material is polyester resin 60%, polylactide 10%, polybutylene succinate 15%, halogen reagent 1%, polycarbonate In the case of 5%, polyethylene terephthalate 8%, and 1% additive, the biodegradability of the polyester resin composition is stronger, and its service life is reduced to a certain extent.

[0044] Working principle: Polyester resin is produced by reacting polyester resin, polylactide, polybutylene succinate, polycarbonate, and polyethylene terephthalate with halogen-based reagents and additives, among which Polylactide and polybutylene succinate have excellent biodegradability, through dissolution, enzymolysis, phagocytosis, etc. in the organism, they are continuously excreted from the body during the process of tissue growth, and repaired accordingly Thereby completely replacing the position of the implanted material, so that the material does not remain in the body, so when the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com