Lubricating grease compound additive and lubricating grease composition prepared from lubricating grease compound additive

A grease composition and compound additive technology, applied in the field of grease additives, can solve problems such as hindering organic extreme pressure agents and chemical protective films on the surface of friction pairs, and achieve stable anti-wear performance, excellent extreme pressure, and improved extreme pressure. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of STAB-ZrP compound: according to mass ratio α-ZrP (Zr(HPO 4 ) 2 ·H 2 O): distilled water (H 2O)=1 : 150 Weigh α-ZrP, after mixing, stir evenly at room temperature, and then according to the molar ratio of methylamine (CH 5 N): α-ZrP (Zr(HPO 4 ) 2 ·H 2 (O) = 1:1 ratio of methylamine was added, stirred at room temperature for 24 hours to obtain methylamine pre-intercalated zirconium phosphate suspension; then according to the molar ratio STAB (C 21 h 46 BrN): α-ZrP (Zr(HPO 4 ) 2 ·H 2 (0) = 1: 1 Weigh STAB and add it to the α-ZrP suspension pre-intercalated with methylamine, stir at room temperature for 24 hours, the product is centrifuged, washed with distilled water, dried at room temperature and air-dried, using X-ray Diffractometer (XRD) was used to characterize the crystal structure, and the content of interlayer organic matter was characterized by elemental analysis of C, H, and N, and STAB-ZrP with an interlayer organic matter cont...

Embodiment 2

[0032] Using the STAB-ZrP (STAB: 44.67 wt.%) prepared in Example 1;

[0033] Basic lithium base grease is prepared with embodiment 1;

[0034] Add 3.0 g STAB-ZrP (STAB: 44.67 wt.%), 0.5 g T746 and 2.0 g BHT as grease additives to 94.5 g of basic lithium-based grease, and use a three-roll mill to roll and grind 3 times to make the additives in the basic lithium Mix well with base grease to obtain a lithium base grease product containing 3.0 wt.% STAB-ZrP (STAB: 44.67 wt.%) (abbreviated as 3.0 wt.% STAB-ZrP (STAB: 44.67 wt.%) lithium base fat).

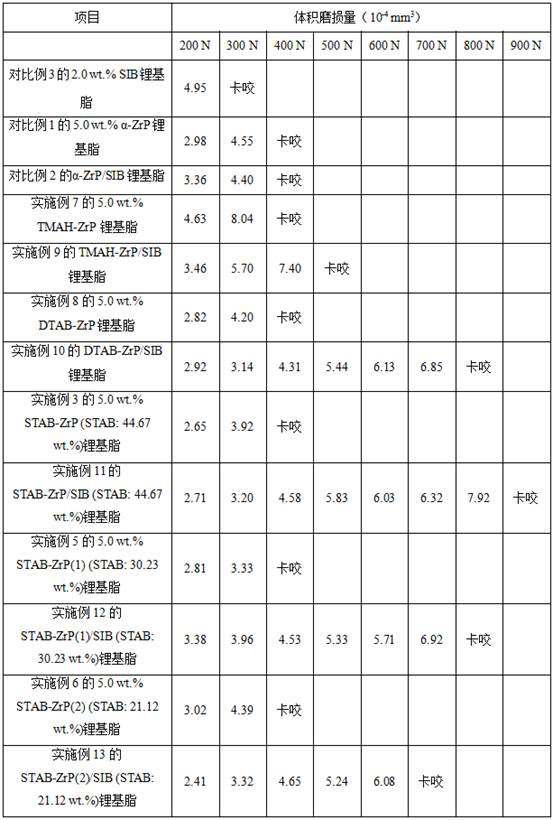

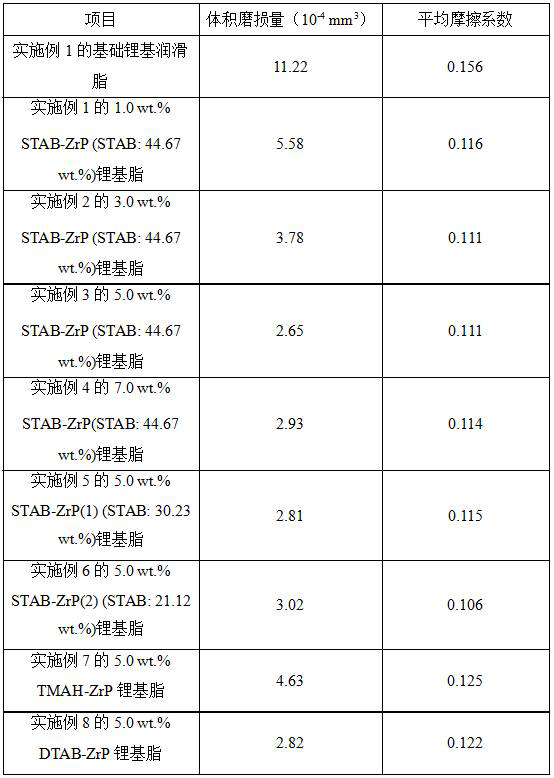

[0035] The SRV-V friction and wear testing machine was used to characterize the anti-wear and anti-friction properties of the prepared lubricating grease products. The load is 200 N, the frequency is 50 Hz, the step size is 1 mm, the temperature is 80 °C, and the time is 30 min. See Table 1 for the data.

Embodiment 3

[0037] Using the STAB-ZrP (STAB: 44.67 wt.%) prepared in Example 1;

[0038] Basic lithium base grease is prepared with embodiment 1;

[0039] Add 5.0 g STAB-ZrP (STAB: 44.67 wt.%), 1.0 g T746 and 1.0 g BHT as grease additives to 93.0 g of basic lithium-based grease, and use a three-roll mill to roll and grind 3 times to make the additives in the basic lithium Mix well with base grease to obtain a lithium base grease product containing 5.0 wt.% STAB-ZrP (STAB: 44.67 wt.%) (abbreviated as 5.0 wt.% STAB-ZrP (STAB: 44.67 wt.%) lithium base fat).

[0040] The SRV-V friction and wear testing machine was used to characterize the anti-wear and anti-friction properties of the prepared lubricating grease products. The frequency is 50 Hz, the step size is 1 mm, the temperature is 80 °C, and the time is 30 min. See Tables 1 and 2 for the data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com