Acrylate copolymer as well as preparation method and application thereof

A technology of acrylates and copolymers, applied in the field of acrylates copolymers and its preparation, can solve the problems of poor compatibility of inorganic anti-opening agents, difficulty in dispersing, film surface properties and printing effects, etc., and achieve the effect of improving the opening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A first aspect of the present invention provides a method for preparing an acrylate copolymer, wherein the method comprises the following steps:

[0021] (1) In an inert atmosphere, the polymerization monomer and the initiator are dissolved in an organic medium to form a homogeneous solution;

[0022] (2) After the homogeneous solution is subjected to a polymerization reaction to obtain a copolymer emulsion suspension, centrifugal separation is performed to obtain the acrylate copolymer;

[0023] Wherein, the polymerized monomer includes maleic anhydride, styrene and the monomer shown in formula (1); based on the total substance amount of the polymerized monomer, the molar content of the maleic anhydride is 47-52% ; The molar ratio of the styrene to the monomer represented by the formula (1) is 10:1-1:10;

[0024] Among them, R 1 selected from H, methyl or ethyl; R 2 It is a straight-chain or branched-chain alkyl group with 1-5 carbon atoms.

[0025] In the presen...

Embodiment 1

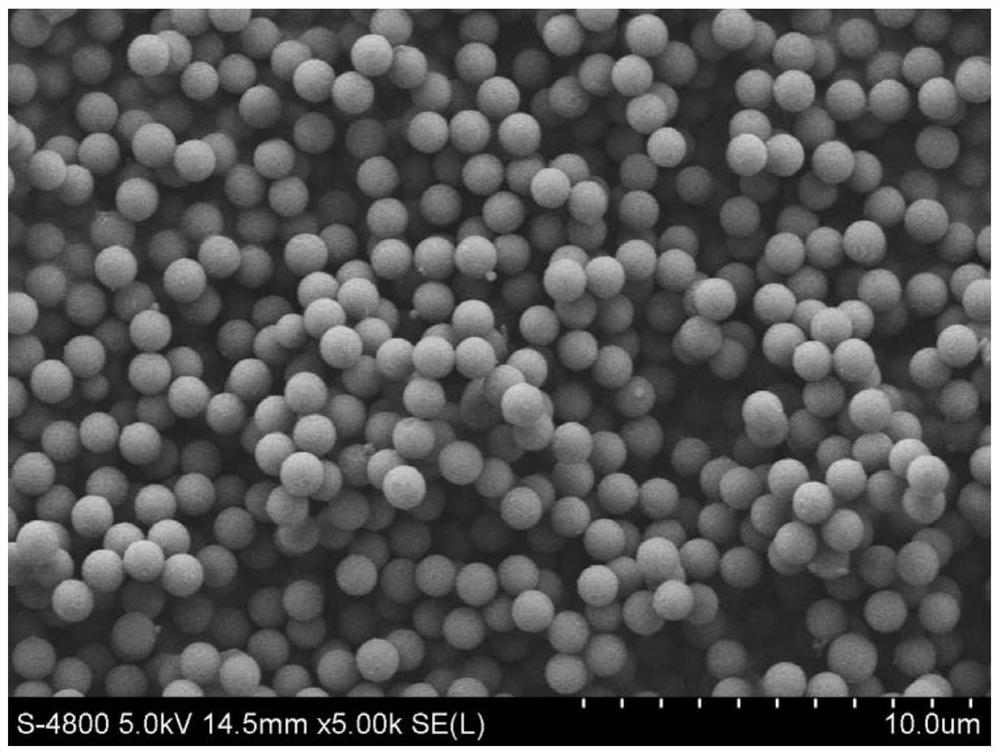

[0068] Add 11g of maleic anhydride, 0.6g of azobisisobutyronitrile, 10g of methyl methacrylate, 1.04g of styrene and 87.8g of isoamyl acetate into a 500mL three-necked flask, and mix the materials uniformly to obtain a homogeneous solution , blow nitrogen for 20 minutes, move the three-necked flask into a water bath at 60°C, and react for 12 hours. After the reaction is completed, the obtained polymer emulsion suspension is centrifuged at a speed of 2000 rad / min for 20 minutes to obtain a polymer solid A1 12.22 g, corresponding to a polymer yield of 61.6%. The particle size of the polymer microspheres is 1200 nm. Wherein, based on the total weight of the homogeneous solution, the concentration of the polymerizable monomer is 20wt%, and the concentration of the initiator is 0.54wt%. Based on the total amount of polymerized monomers, the molar content of maleic anhydride is 50.5%, and the molar ratio of styrene to methyl methacrylate is 1:10.

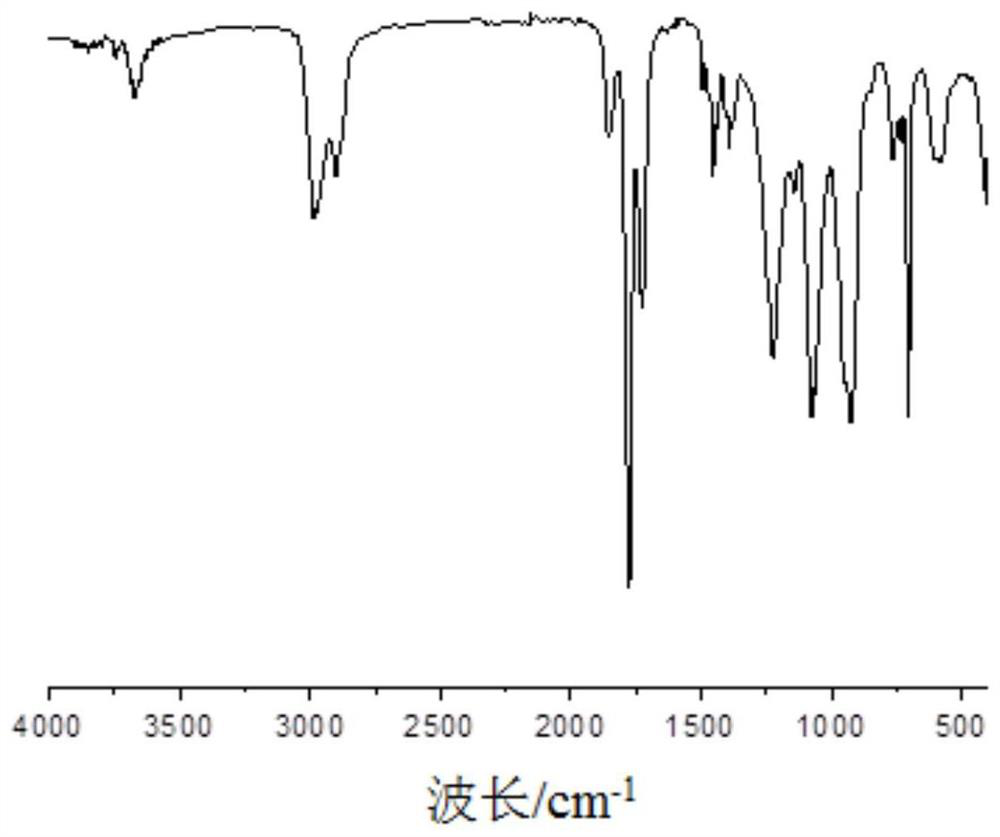

[0069] The polymer microsphere A...

Embodiment 2

[0073] Add 10.5g maleic anhydride, 0.89g azobisisobutyronitrile, 11.4g ethyl methacrylate, 2.08g styrene and 87.8g butyl butyrate into a 500mL three-necked flask, and mix the materials uniformly to obtain a homogeneous Solution, blow nitrogen for 20 minutes, move the three-neck flask into a 70°C water bath, and react for 5 hours. After the reaction is completed, the obtained polymer emulsion suspension is centrifuged at a speed of 2000rad / min for 20 minutes to obtain a polymer solid A2 13.9 g, corresponding to a polymer yield of 58%. The particle size of the polymer microspheres is 1500 nm. Wherein, based on the total weight of the homogeneous solution, the concentration of the polymerizable monomer is 20.9wt%, and the concentration of the initiator is 0.79wt%. Based on the total amount of polymerized monomers, the molar content of maleic anhydride was 47.8%, and the molar ratio of styrene to ethyl methacrylate was 1:5.

[0074] The polymer microsphere A2 was carried out 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com