Alpha-olefin-maleic anhydride copolymer as well as preparation method and application thereof

A maleic anhydride and copolymer technology, which is applied in the field of alpha-olefin-maleic anhydride copolymer microspheres and their preparation, can solve the problems of reduced polyolefin performance, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The second aspect of the present invention provides a kind of preparation method of α-olefin-maleic anhydride copolymer, wherein, described method comprises the following steps:

[0041] (1) In an inert atmosphere, the polymerization monomer and the initiator are dissolved in an organic medium to form a homogeneous solution;

[0042] (2) After the homogeneous solution is subjected to a polymerization reaction to obtain a copolymer emulsion suspension, centrifugal separation is performed to obtain the α-olefin-maleic anhydride copolymer;

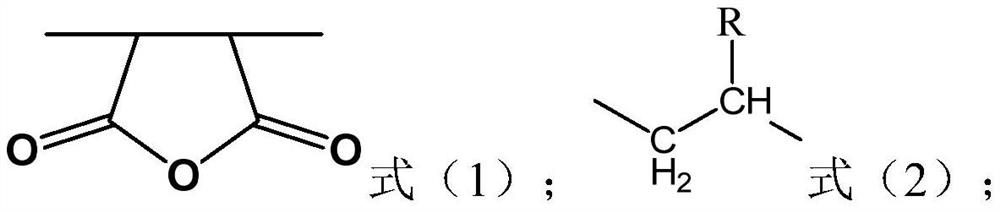

[0043] Wherein, the polymerized monomer is maleic anhydride and the α-olefin shown in formula (3); based on the total substance amount of the polymerized monomer, the molar content of the maleic anhydride is 48-53%, and the α - the molar content of olefins is 47-52%;

[0044]

[0045] Wherein, R is an alkane with 6-12 carbon atoms.

[0046] In the present invention, in the presence of an organic medium, the α-olefin shown in malei...

Embodiment 1

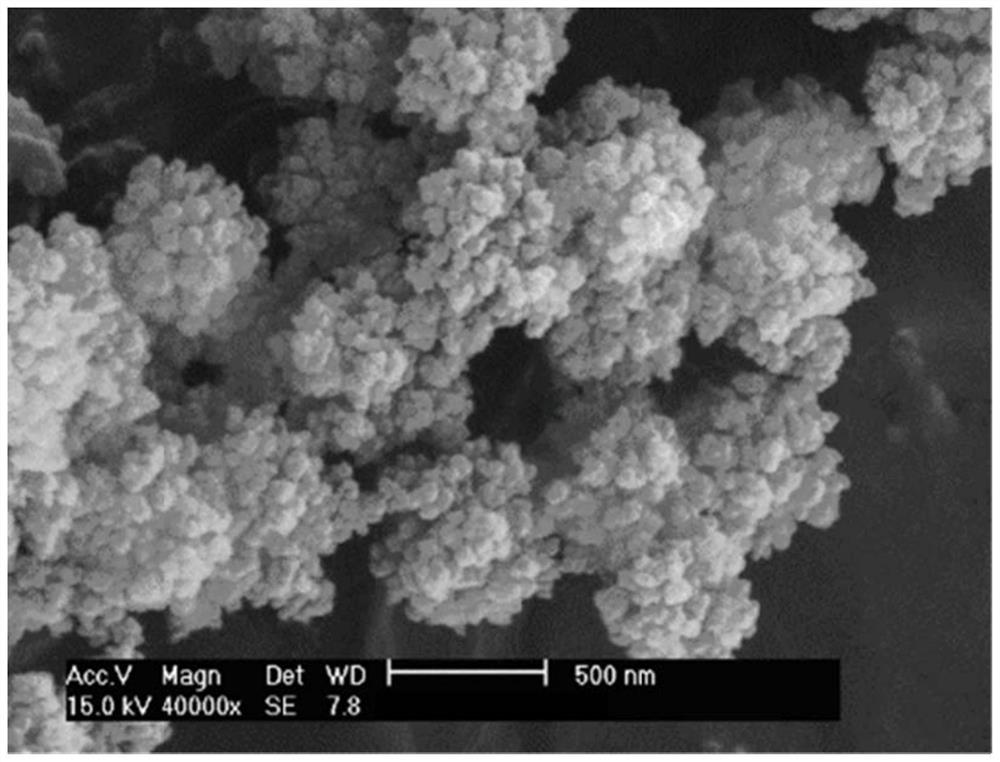

[0084] Add 11g of maleic anhydride, 0.6g of azobisisobutyronitrile, 8.4g of hexene, 90mL of hexane, and 87.8g of isoamyl acetate into a 500mL three-necked flask. After the materials are mixed evenly, a homogeneous solution is obtained. For 20 minutes, move the three-necked flask into a water bath at 60°C and react for 24 hours. After the reaction is completed, the obtained polymer emulsion suspension is centrifuged at a speed of 2000 rad / min for 20 minutes to obtain 9.7 g of polymer solid A1, corresponding to Polymer yield 50%. The particle size of the polymer microspheres is 1600 nm. Wherein, based on the total weight of the homogeneous solution, the concentration of the polymerizable monomer is 11.6wt%, and the concentration of the initiator is 0.36wt%.

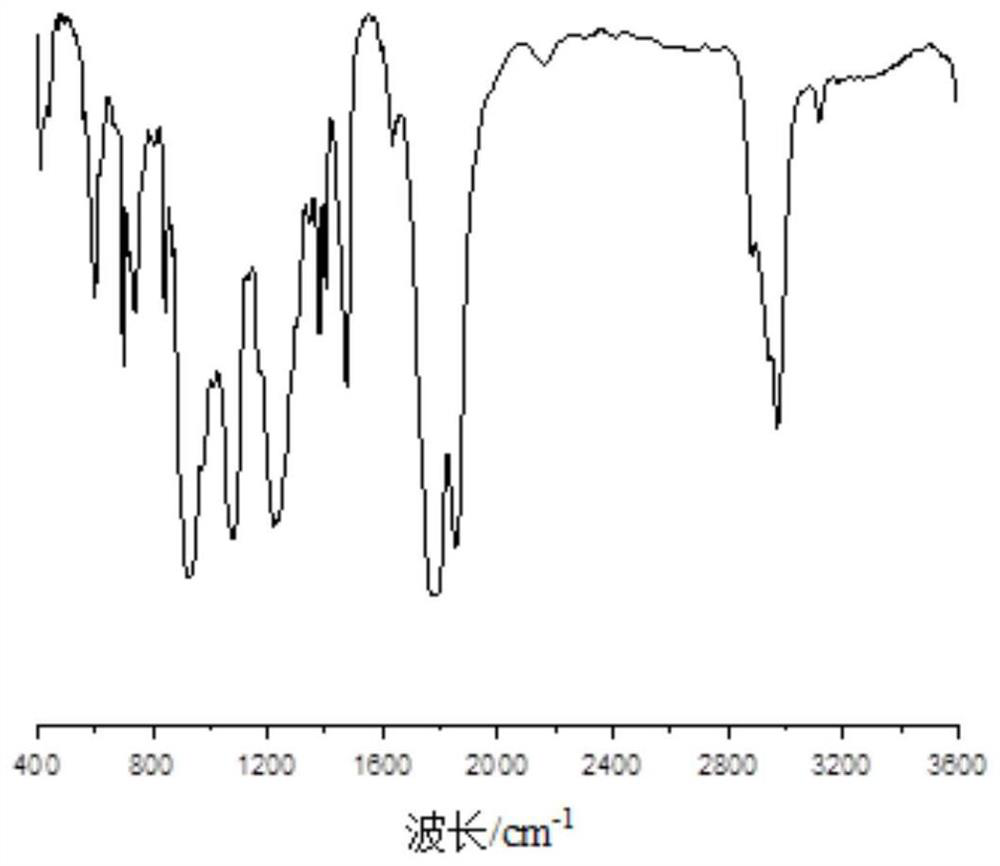

[0085] The polymer microsphere A1 was carried out 1 According to H NMR measurement, in the polymer, the molar content of the structural unit provided by maleic anhydride is 50%, and the molar content of the structural uni...

Embodiment 2

[0089] Add 20g of maleic anhydride, 0.2g of azobisisobutyronitrile, 70mL of hexane, 17.2g of hexene and 87.8g of butyl butyrate into a 500mL three-necked flask. After the materials are mixed evenly, a homogeneous solution is obtained. Minutes, the three-neck flask was moved into a 95°C water bath, and reacted for 2 hours. After the reaction was completed, the obtained polymer emulsion suspension was centrifuged at a speed of 2000rad / min for 20 minutes to obtain 8.9g of polymer solid A2, corresponding to polymer Yield 48%. The particle size of the polymer microspheres is 1500 nm. Wherein, based on the total weight of the homogeneous solution, the concentration of the polymerizable monomer is 21.6wt%, and the concentration of the initiator is 0.12wt%.

[0090] The polymer microsphere A2 was carried out 1 According to H NMR measurement, in the polymer, the molar content of structural units provided by maleic anhydride is 48%, and the molar content of structural units provided b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com