Catalyst for producing unsaturated aromatic hydrocarbon by dehydrogenating saturated aromatic hydrocarbon and application of catalyst

A catalyst and unsaturated technology, applied in the direction of catalysts, molecular sieve catalysts, carbon compound catalysts, etc., can solve the problems of hindering the agglomeration of active components, complex composition of catalyst elements, and long manufacturing process, so as to maintain activity and selectivity, solve Long-term stability issues, effects of high activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

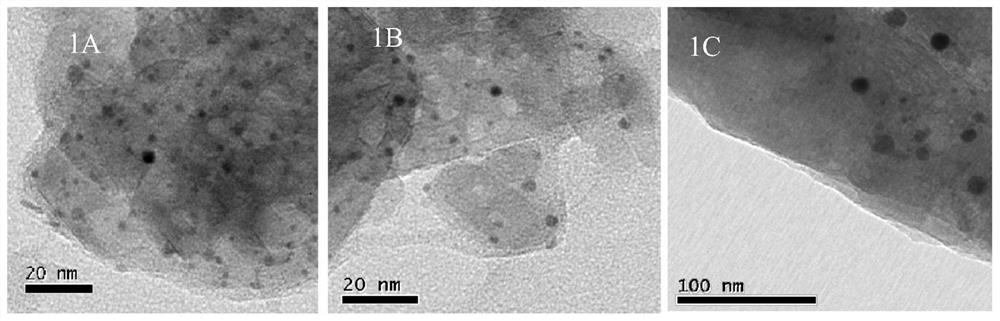

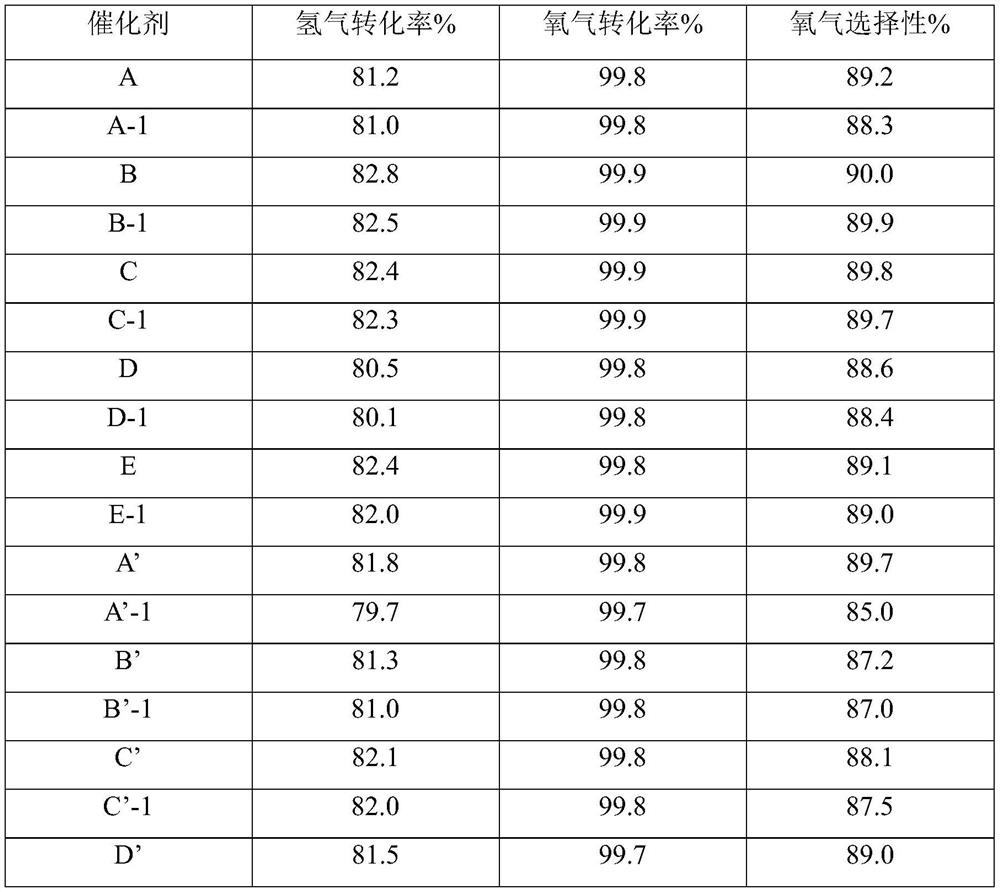

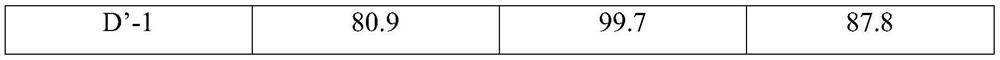

[0043] Add 15g of ZSM-5 molecular sieve powder to 600mL of 0.1mol / L chloroplatinic acid aqueous solution at 80°C, and perform ion exchange for 8 hours under stirring. After ion exchange, filter, wash the filtered solid with 1 L of deionized water, and filter again. The washed filtered solid was dried at 120°C, followed by calcination at 500°C for 4 hours. After cooling, the agglomerated solid was ground into a fine powder to obtain a Pt-bound ZSM-5 molecular sieve.

[0044] Weigh the above steps to obtain 10g of ZSM-5 molecular sieve combined with Pt, and then weigh the specific surface to be 8m 2 Add 40 g of α-alumina per gram into 200 mL of water and stir to disperse, then add 7.5 g of 20% aluminum sol, and stir for 1 hour to obtain a coating material suspension.

[0045] Take 176g of the coating material suspension obtained in the above steps, and apply it to 200g of cordierite cores by spraying. Then it was dried at 120°C for 2 hours, and then calcined at 650°C for 6 ho...

Embodiment 2

[0049] Add 15g of ZSM-5 molecular sieve powder into 500mL of 0.2mol / L chloroplatinic acid aqueous solution at 80°C, and perform ion exchange for 8 hours under stirring. After ion exchange, filter, wash the filtered solid with 1 L of deionized water, and filter again. The washed filtered solid was dried at 120°C, followed by calcination at 500°C for 4 hours. After cooling, the agglomerated solid was ground into a fine powder to obtain a Pt-bound ZSM-5 molecular sieve.

[0050] Weigh the above steps to obtain 10g of ZSM-5 molecular sieve combined with Pt, and then weigh the specific surface to be 8m 2 Add 40 g of α-alumina per gram into 200 mL of water and stir to disperse, then add 7.5 g of 20% aluminum sol, and stir for 1 hour to obtain a coating material suspension.

[0051] Take 176g of the coating material suspension obtained in the above steps and apply it to 105g of cordierite cores by spraying. Then it was dried at 120°C for 2 hours, and then calcined at 650°C for 6 h...

Embodiment 3

[0055] Add 15g of ZSM-5 molecular sieve powder to 600mL of 0.12mol / L chloroplatinic acid aqueous solution at 80°C, and perform ion exchange for 8 hours under stirring. After ion exchange, filter, wash the filtered solid with 1 L of deionized water, and filter again. The washed filtered solid was dried at 120°C, followed by calcination at 500°C for 4 hours. After cooling, the agglomerated solid was ground into a fine powder to obtain a Pt-bound ZSM-5 molecular sieve.

[0056] Weigh the above steps to obtain 10g of ZSM-5 molecular sieve combined with Pt, and then weigh the specific surface to be 5m 2 Add 40 g of α-alumina per gram into 200 mL of water and stir to disperse, then add 7.5 g of 20% aluminum sol, and stir for 1 hour to obtain a coating material suspension.

[0057] Take 176g of the coating material suspension obtained in the above steps and apply it to 105g of cordierite cores by spraying. Then it was dried at 120°C for 2 hours, and then calcined at 650°C for 6 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com