Cobalt-containing monatomic catalyst as well as macro preparation method and application thereof

A catalyst and atom technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the complex and difficult to control the preparation process of cobalt single-atom catalysts, the low yield of cobalt single-atom catalysts, and the unfriendly environment. and other problems, to achieve the effects of efficient atomic utilization, high cost-effectiveness of raw materials, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for the macro-preparation of a cobalt-containing single-atom catalyst, comprising the following steps:

[0036] 1) Disperse 1 mmol of 3-aminophenol and 2 mmol of hexamethylenetetramine in water, add 0.2 mmol of cetyltrimethylammonium bromide as a shape-directing agent, react at 85°C for 24 hours, and freeze-dry Obtain phenolic resin fiber;

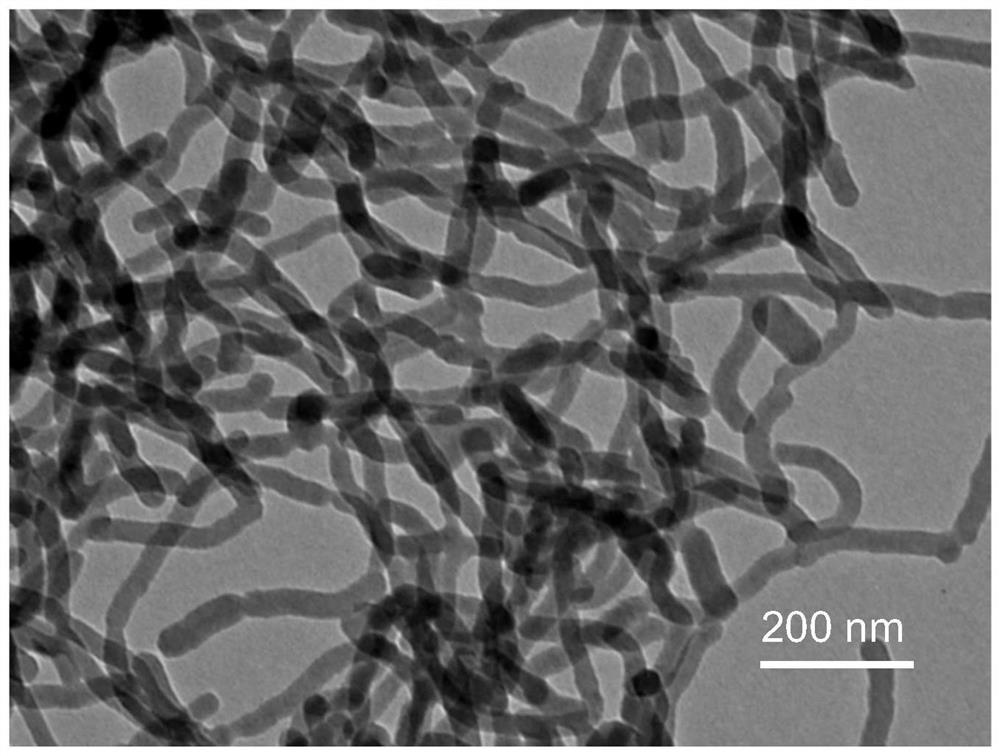

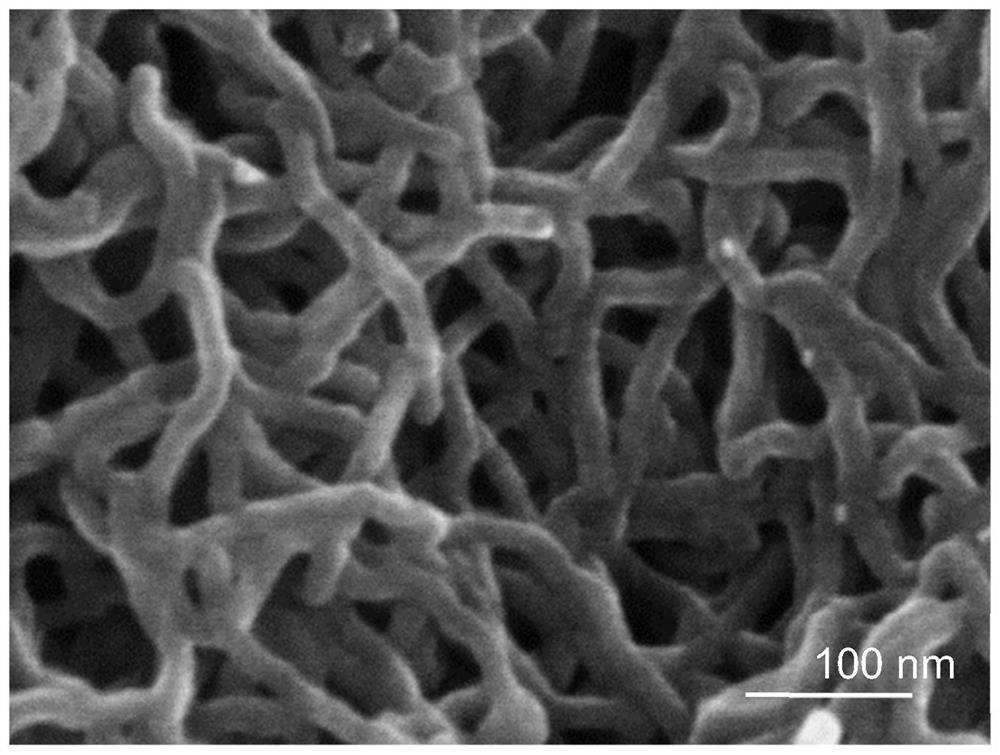

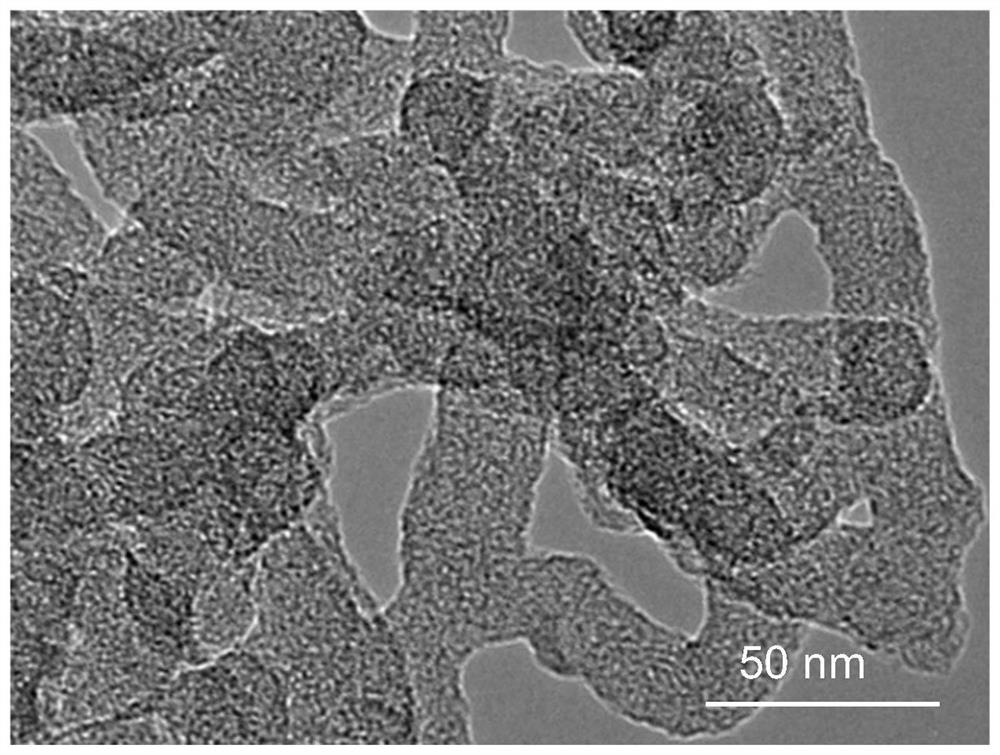

[0037] 2) Weigh 0.3g of phenolic resin fiber, add 30 mL of 0.1 mol / L cobalt nitrate mixed solution, stir at 25°C for 12 hours at a stirring speed of 200 r / min, centrifuge and freeze-dry the precipitate and freeze-dry the obtained product In an inert atmosphere, the carbonization temperature is 900°C, and the temperature is kept for 60 minutes to obtain the cobalt-containing single-atom catalyst, which is denoted as Co-SA@N-CNFs;

[0038] 3) Increasing the feed amount of the precursor and using a larger reactor can realize the macro-production of cobalt-containing single-atom catalysts, such as Figure 5 shown.

[0039]...

Embodiment 2

[0051] A method for the macro-preparation of a cobalt-containing single-atom catalyst, comprising the following steps:

[0052] 1) Disperse 1 mmol of 3-aminophenol and 1 mmol of hexamethylenetetramine in water, add 0.2 mmol of cetyltrimethylammonium bromide as a shape-directing agent, react at 85°C for 24 hours, and freeze-dry Obtain phenolic resin fiber;

[0053] 2) Weigh 0.3g of phenolic resin fiber, add 30 mL of 0.1 mol / L cobalt nitrate mixed solution, stir at 25°C for 12 hours at a stirring speed of 200 r / min, centrifuge and freeze-dry the precipitate and freeze-dry the obtained product In an inert atmosphere, the carbonization temperature is 900° C., and the temperature is kept for 60 minutes to obtain the final product.

Embodiment 3

[0055] A method for the macro-preparation of a cobalt-containing single-atom catalyst, comprising the following steps:

[0056] 1) Disperse 1 mmol of 3-aminophenol and 3 mmol of hexamethylenetetramine in water, add 0.2 mmol of cetyltrimethylammonium bromide as a shape-directing agent, react at 85°C for 24 hours, and freeze-dry Obtain phenolic resin fiber;

[0057] 2) Weigh 0.3g of phenolic resin fiber, add 30 mL of 0.1 mol / L cobalt nitrate mixed solution, stir at 25°C for 12 hours at a stirring speed of 200 r / min, centrifuge and freeze-dry the precipitate and freeze-dry the obtained product In an inert atmosphere, the carbonization temperature is 900° C., and the temperature is kept for 60 minutes to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com