Metal-organic framework material separation membrane as well as preparation method and application thereof

An organic framework and separation membrane technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problem of difficult to obtain MOFs separation functional layer, weak combination of separation functional layer and basement membrane, specific material selectivity Difficult to improve and other problems, to achieve the effects of excellent chemical dissolution resistance, high temperature resistance, large flux and separation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

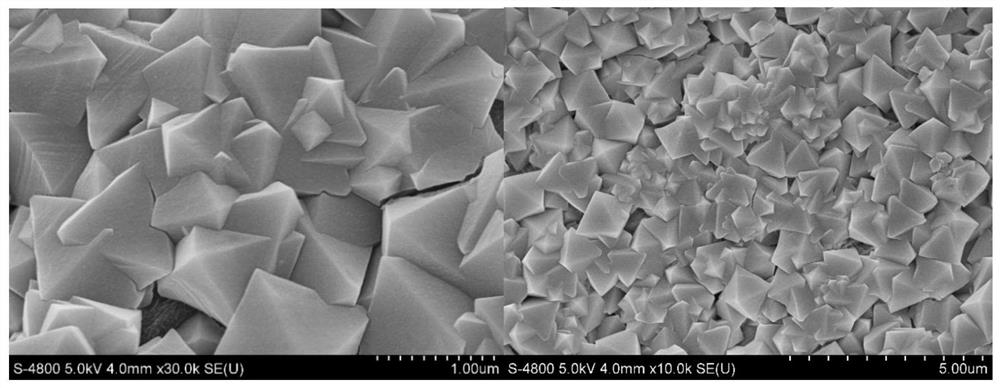

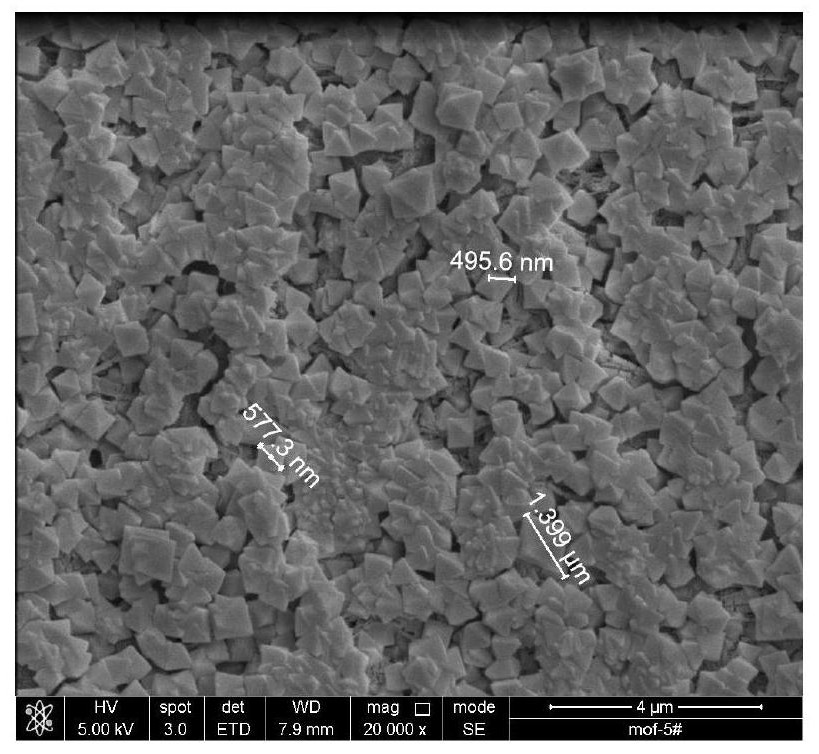

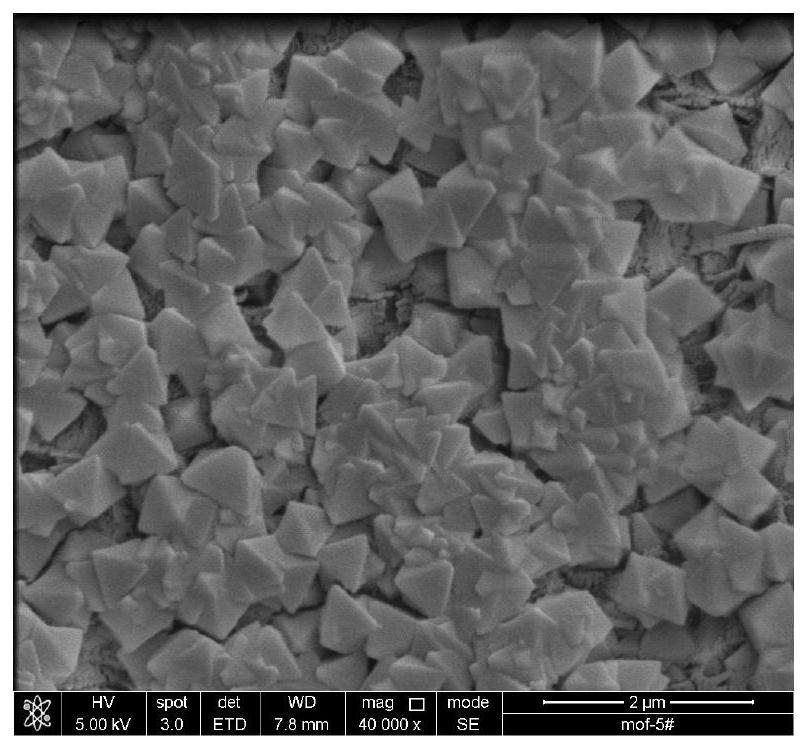

Image

Examples

Embodiment 1

[0191] (1) Solution required for MOFs membrane preparation

[0192] N-methylpyrrolidone, terephthalic acid, zirconium tetrachloride and pure water are mixed according to the molar ratio of 400:1:1:0.01 and fully stirred to obtain the solution required for the preparation of the MOFs membrane.

[0193] (2) Basement membrane pretreatment

[0194] (a) Mix polyacrylic acid, partially hydrolyzed polyacrylic acid, polyvinyl alcohol and zirconium tetrachloride at a molar ratio of 2:1 with a mass concentration of 1000 mg / L, and stir for 1 hour to obtain a reacted solution;

[0195] (b) After the polypropylene hollow fiber base membrane with a pore size of 500nm is washed with water, washed with ethanol and dried, the ratio of the surface area of the base membrane to the solution described in (a) is 1m 2 / L (that is, the film with a surface of 1 square meter is coated with 1L of the preparation solution described in step (a)), the solution generated in (a) is coated on the surface o...

Embodiment 2

[0202] The difference from Example 1 is only that in (2) basement membrane pretreatment, according to the ratio of the basement membrane surface area and the solution described in (a), it is 0.1m 2 / L (that is, the film with a surface of 0.1 square meters is coated with 1 L of the solution prepared in step (a)), and the solution generated in (a) is coated on the surface of the dried base film.

[0203] The performance test data of the membrane is shown in Table 1. The performance test data of the membrane show that the flux of nitrogen gas at 0.1Mpa can reach 2.01×10 -6 mol / (m 2 ·s·Pa), while the flux of propylene gas is only 0.18×10 - 6 mol / (m 2 s Pa), the nitrogen / propylene separation coefficient is 11.17.

Embodiment 3

[0205] The difference with Example 1 is only that in (2) basement membrane pretreatment, according to the ratio of the basement membrane surface area and the solution described in (a), be 5m 2 / L (that is, a film with a surface of 5 square meters is coated with 1 L of the solution prepared in step (a)), and the solution generated in (a) is coated on the surface of the dried base film.

[0206] The performance test data of the membrane is shown in Table 1. The performance test data of the membrane show that the flux of nitrogen gas at 0.1Mpa can reach 10.41×10 -6 mol / (m 2 ·s·Pa), while the flux of propylene gas is only 1.206×10 - 6 mol / (m 2 s Pa), the nitrogen / propylene separation coefficient is 8.63.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com