Positive electrode host material as well as preparation method and application thereof

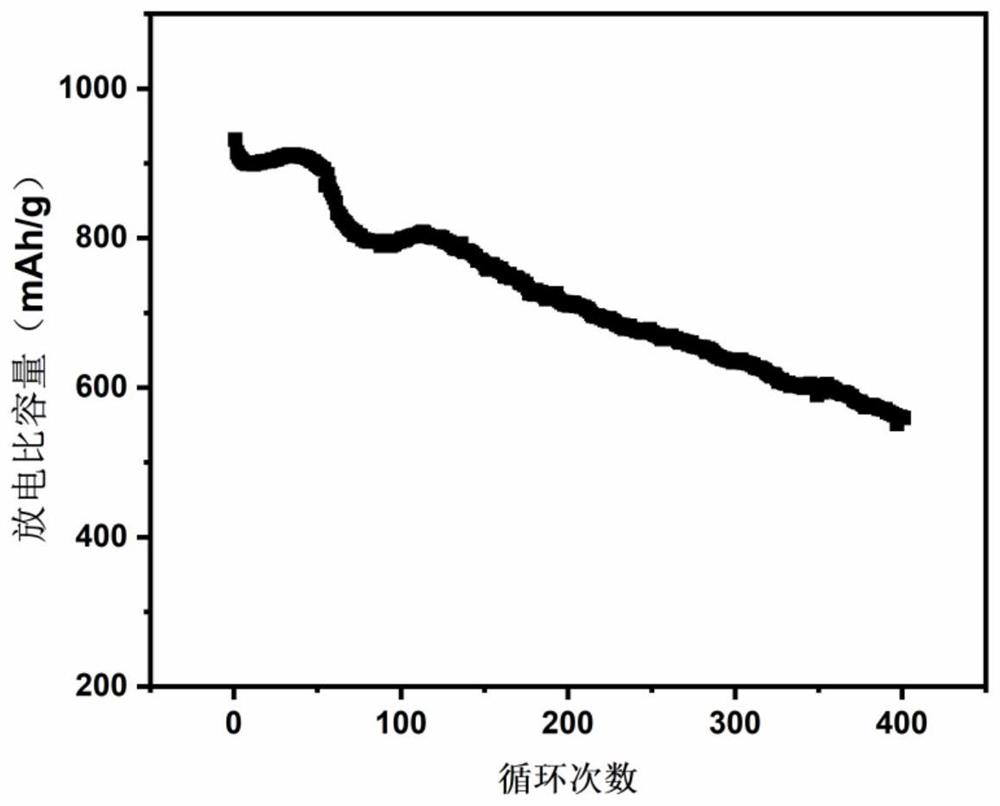

A technology of host material and positive electrode, applied in the field of positive host material and its preparation, can solve the problems of few catalytic active sites, poor ionic conductivity, small specific surface area, etc., and achieve the effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

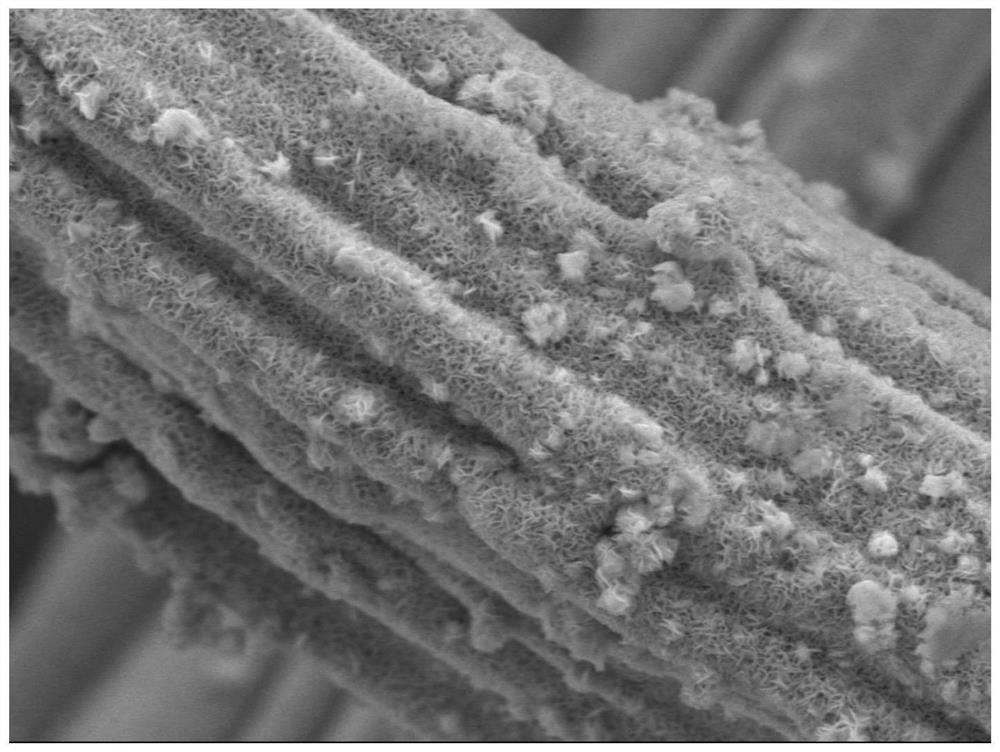

[0050] This embodiment provides a positive electrode host material, and the preparation method of the positive electrode host material is as follows:

[0051] (1) (1.09mmol) 284mg SnCl 2 and (0.36mmol) 73mg Co(NO 3 ) 2 ·H 2 O was dissolved in 40 mL deionized water, and solution A was obtained by ultrasonic-assisted method. Then (2mmol) 152mg CS(NH 2 ) 2Dissolve in 40mL deionized water, and obtain solution B by ultrasonic-assisted method. Then add solution A to solution B drop by drop, stir magnetically for 30 minutes while dropping, and then transfer to a clean 6cm 2 In the hydrothermal reactor of carbon cloth, react for 12h at 160°C. Take out the carbon cloth, wash it 4 times with deionized water, and freeze-dry overnight to obtain a yellow carbon cloth layer;

[0052] (2) Put 0.5g of sodium hypophosphite powder in a small magnetic boat, put it on one side of the tube furnace, arrange the above-mentioned carbon at the other end of the tube furnace, and put it at 350°C...

Embodiment 2

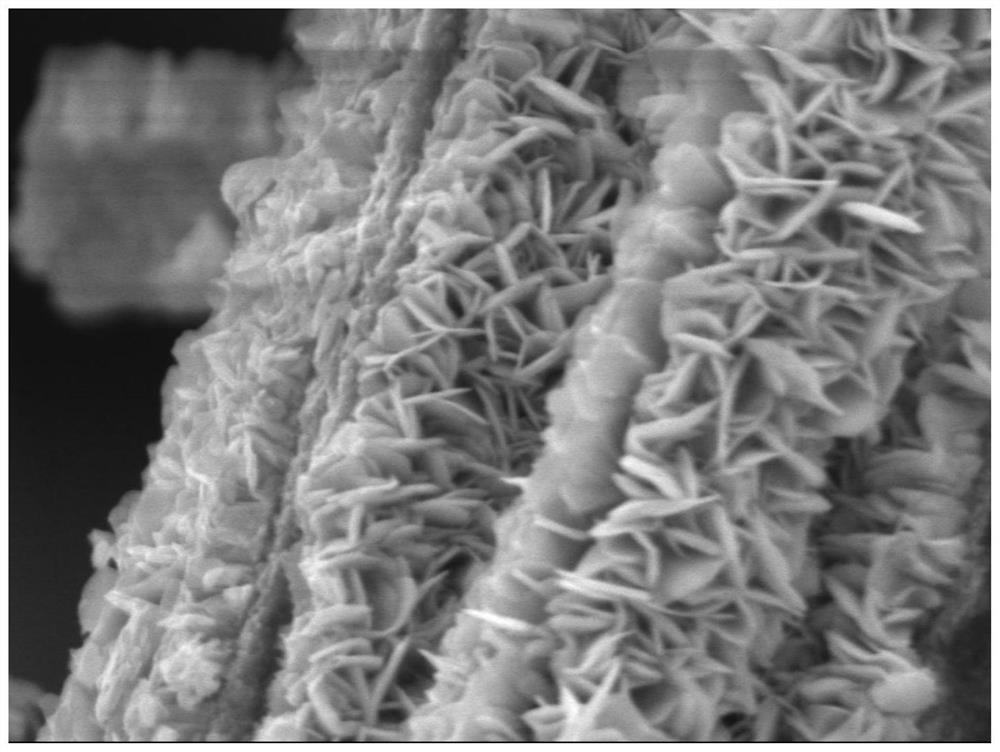

[0055] This embodiment provides a positive electrode host material, and the preparation method of the positive electrode host material is as follows:

[0056] (1) (1mmol) 260mg SnCl 2 and (0.3mmol) 54mg Mn(NO 3 ) 2 Dissolve in 40mL deionized water, and obtain Solution A by ultrasonic-assisted method. Then (2mmol) 152mg CS(NH 2 ) 2 Dissolve in 40mL deionized water, and obtain solution B by ultrasonic-assisted method. Then add solution A to solution B drop by drop, stir magnetically for 30 minutes while dropping, and then transfer to a clean 6cm 2 In the hydrothermal reactor of carbon felt, react for 12 hours at 165°C. Take out the carbon felt, wash it 4 times with deionized water, and freeze-dry overnight to obtain a yellow carbon cloth layer;

[0057] (2) Put 0.5g of sodium hypophosphite powder in a small magnetic boat, put it on one side of the tube furnace, put the above-mentioned carbon felt on the other end of the tube furnace, and put it under N at 350°C 2 Calcine...

Embodiment 3

[0059] The only difference between this embodiment and embodiment 1 is that Co(NO 3 ) 2 ·H 2 The quality of O is 40 mg (0.2 mmol), and other conditions and parameters are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com