Production method of P265GH steel plate with good low-temperature impact toughness

A technology of low temperature impact toughness and production method, applied in the field of metallurgy, can solve the problems of high production cost, uneven structure of steel plate, unstable impact performance of steel plate, etc., and achieve the effect of low production cost, stable comprehensive performance and improved impact performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

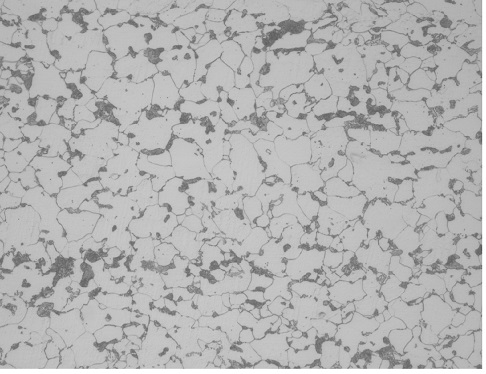

Image

Examples

Embodiment 1

[0016] In this example, the thickness of the P265GH steel plate is 60mm. Among the steel plate components, C: 0.12wt%, Mn: 1.10wt%, Nb: 0.015wt%, P: 0.007wt%, S: 0.003wt%, and the remaining alloy elements and mass percentages meet the EN10028 standard Require. Its production method includes smelting, rolling and heat treatment processes, and the steps are as follows:

[0017] (1) Smelting process: control the superheat of the tundish to 15°C; turn on the electromagnetic stirring device during the continuous casting process: the stirring current is 400A, the frequency is 40Hz, the end of the continuous casting is lightly reduced to improve the internal quality of the billet, and the dynamic reduction is 3mm;

[0018] (2) Rolling process: the rough rolling stage and the finishing rolling stage ensure that the rolling reduction of 2 passes is 30mm, and the rough rolling is 2.2 times the thickness of the finished steel plate before finishing rolling; in order to ensure the penetra...

Embodiment 2

[0022] In this example, the thickness of the P265GH steel plate is 65mm. Among the components of the steel plate, C: 0.14wt%, Mn: 1.30wt%, Nb: 0.020wt%, P: 0.006wt%, S: 0.002wt%, and the remaining alloy elements and mass percentages meet the EN10028 standard Require. Its production method includes smelting, rolling and heat treatment processes, and the steps are as follows:

[0023] (1) Smelting process: control the superheat of the tundish to 30°C; turn on the electromagnetic stirring device during the continuous casting process: the stirring current is 450A, the frequency is 60Hz, the end of the continuous casting is lightly reduced to improve the internal quality of the slab, and the dynamic reduction is 5mm;

[0024] (2) Rolling process: the rough rolling stage and the finishing rolling stage ensure that the rolling reduction of 3 passes is 35mm, and the rough rolling is 2.5 times the thickness of the finished steel plate before finishing rolling; Water spray cooling, wat...

Embodiment 3

[0028] In this example, the thickness of the P265GH steel plate is 70mm. Among the components of the steel plate, C: 0.13wt%, Mn: 1.15wt%, Nb: 0.017wt%, P: 0.005wt%, S: 0.002wt%, and the rest of the alloy elements and mass percentages meet the EN10028 standard Require. Its production method includes smelting, rolling and heat treatment processes, and the steps are as follows:

[0029] (1) Smelting process: control the superheat of the tundish to 20°C; turn on the electromagnetic stirring device during the continuous casting process: the stirring current is 420A, the frequency is 50Hz, the end of the continuous casting is lightly reduced to improve the internal quality of the slab, and the dynamic reduction is 4mm;

[0030] (2) Rolling process: the rough rolling stage and the finishing rolling stage ensure that the rolling reduction of 2 passes is 32mm, and the rough rolling is 2.3 times the thickness of the finished steel plate before finishing rolling; in order to ensure the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impact absorption energy | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com