Low-density interior calcium silicate board as well as preparation method and application thereof

A calcium silicate board, low-density technology, applied in covering/lining, construction, building construction, etc., can solve the problems of high plant fiber consumption, low board surface strength, and increased production costs, so as to reduce production costs and reduce The effect of heat consumption and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

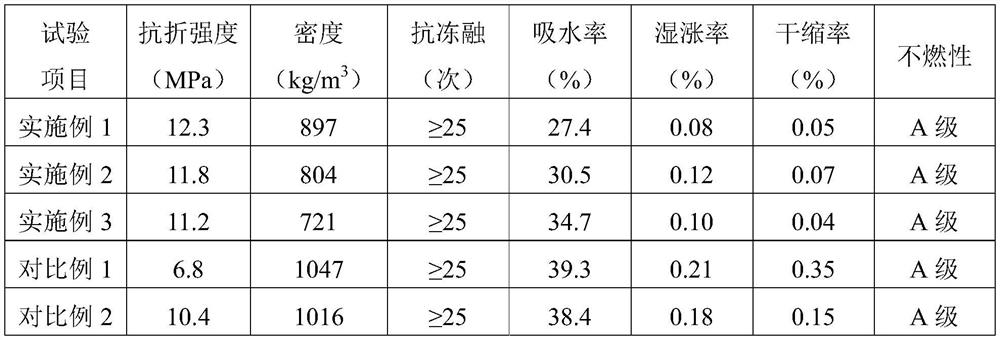

Examples

Embodiment 1

[0053] Embodiment 1 Preparation of low-density interior calcium silicate board

[0054] (1) Preparation of hollow silica microspheres:

[0055] ①Using the emulsion method to prepare hollow silica microsphere emulsion, firstly, nano-silica particles with a particle size of 10nm were added to the oil phase (silicone oil) to obtain a nano-silica suspension with a solid content of 20wt%. Thoroughly stir at 60°C to obtain suspension A;

[0056] 2. the suspension A that step 1. is obtained is under the condition of continuous stirring, gradually add the aqueous solution that concentration is the surfactant (sodium lauryl sulfate) of 10wt%, and the addition is 50% ( v / v), and then add sodium hydroxide solution (mass fraction 4%), adjust the pH value of the system to be 13, obtain the pre-reaction emulsion B;

[0057] ③Heat the pre-reaction emulsion B to 200°C and keep it warm for 2 hours to complete the prepolymerization reaction of hollow silica microspheres. After centrifugation an...

Embodiment 2

[0063] Embodiment 2 Preparation of low-density interior calcium silicate board

[0064] (1) Preparation of hollow silica microspheres:

[0065] ①Using the emulsion method to prepare the hollow silica microsphere emulsion, first adding nano-silica particles with a particle size of 50nm into the oil phase (cyclohexane) to obtain a nano-silica suspension with a solid content of 35wt%, And fully stirred at 60°C to obtain suspension A;

[0066] 2. the suspension A that step 1. is obtained is under the condition of continuous stirring, gradually adds the aqueous solution that concentration is the surfactant (polyethylene glycol monolaurate) of 10wt%, and the add-on is oily phase (cyclohexane) volume 50% (v / v), and then add sodium hydroxide solution (mass fraction 8%), adjust the pH value of the system to be 13, obtain pre-reaction emulsion B;

[0067] ③Heat the pre-reaction emulsion B to 200°C and keep it warm for 2 hours to complete the prepolymerization reaction of hollow silica...

Embodiment 3

[0073] Embodiment 3 Preparation of low-density interior calcium silicate board

[0074] (1) Preparation of hollow silica microspheres:

[0075] ①Use the emulsion method to prepare the hollow silica microsphere emulsion. First, add nano-silica particles with a particle size of 100nm to the oil phase (mixture of silicone oil, cyclohexane and kerosene, and the mass ratio is methyl silicone oil:cyclohexane : kerosene=5:3:2), to obtain a nano-silica suspension with a solid content of 50wt%, and fully stir it at 60°C to obtain a suspension A;

[0076] 2. With the suspension A obtained in step 1. under the condition of continuous stirring, gradually add the aqueous solution with a concentration of 10wt% surfactant (polyoxyethylene lauryl ether), and the addition amount is 50% of the volume of the oil phase (cyclohexane) (v / v), and then add sodium hydroxide solution (mass fraction 12%), adjust the pH value of the system to 13, obtain the pre-reaction emulsion B;

[0077] ③Heat the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com