Rigid-flexible fused capacitive flexible MEMS ultrasonic transducer and preparation method thereof

An ultrasonic transducer, capacitive technology, applied in the direction of electric solid devices, piezoelectric/electrostrictive/magnetostrictive devices, instruments, etc., can solve the difficulty in realizing high-density flexible CMUTs two-dimensional transducer array micromachining , It is impossible to solve the problems of the mutual restriction of the design of the flexible performance of the transducer frequency design, and the difficulty of realizing the design of the high density/high filling factor transducer array element, so as to improve the output sound pressure and receiving sensitivity, stable working performance, and prevent bending deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

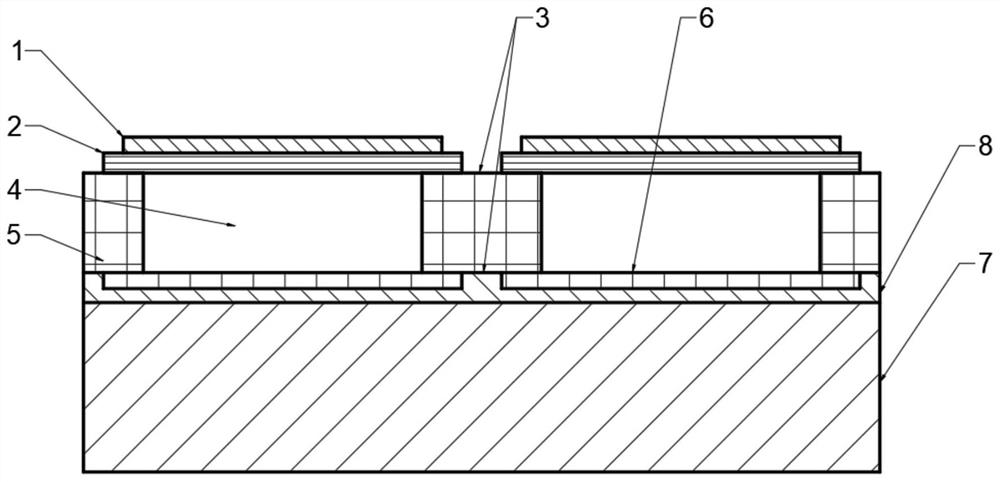

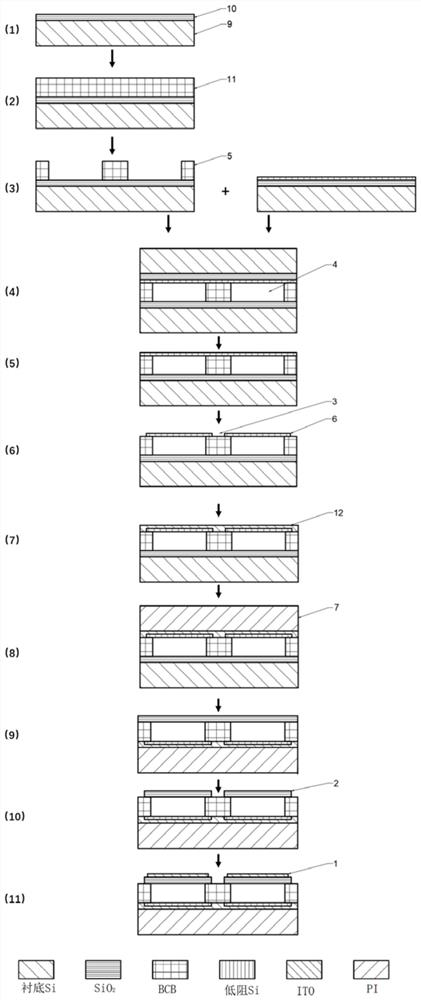

[0041] like figure 1 As shown, the rigid-flexible capacitive flexible MEMS ultrasonic transducer of this embodiment includes a flexible upper electrode 1, a rigid vibrating membrane 2, a groove 3, a cavity 4, a flexible pillar 5, a rigid lower electrode 6, a flexible base 7 and a flexible The conductive layer 8; wherein the rigid vibrating film 2, the flexible pillar 5 and the rigid lower electrode 6 are sequentially arranged from top to bottom and seal the cavity 4 together; the area where the rigid lower electrode 6 and the rigid vibrating film 2 contact the flexible pillar 5 It is penetrated by grooves 3 in the thickness direction, the grooves 3 are used as gaps between the rigid vibrating membranes 2 of adjacent transducing units, and the grooves 3 are used as gaps between the rigid lower electrodes 6 of adjacent transducing units. The flexible upper electrode 1 , the rigid vibrating membrane 2 , the cavity 4 and the rigid lower electrode 6 have the same shape;

[0042] A...

Embodiment 2

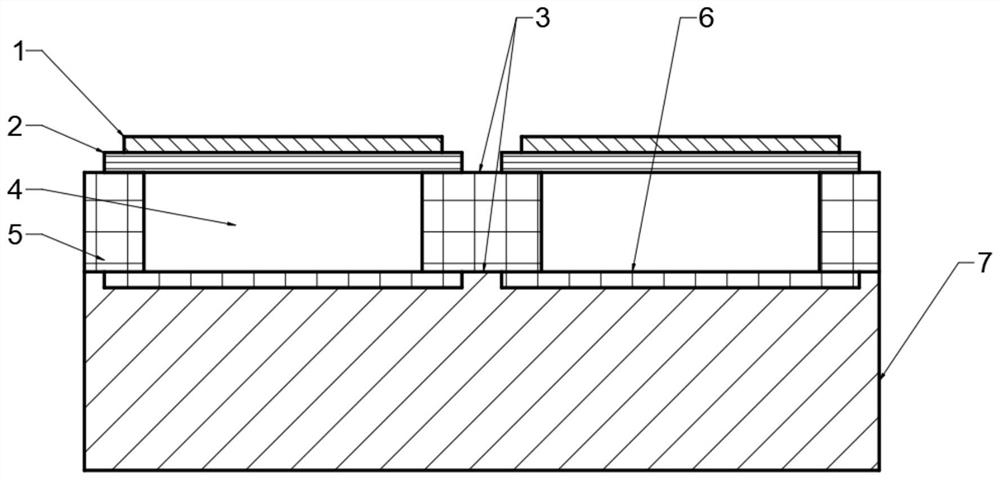

[0062] figure 2 Shown is a schematic diagram of another rigid-flexible fusion capacitive flexible MEMS ultrasonic transducer of the present invention, which is the variable structure of the rigid-flexible capacitive flexible MEMS ultrasonic transducer in Embodiment 1, and the variable structure is the same as figure 1 The difference in the structure of the shown embodiment 1 is that there is no need to set the conductive layer 8, and the material of the flexible substrate 7 is directly replaced by flexible conductive materials such as ITO, PEDOT:PSS, so as to realize the electrical connection between adjacent lower electrodes 6 . In the preparation process, this embodiment is similar to Embodiment 1, except that in step (7), PI is directly spin-coated on the rigid lower electrode 6 to form a flexible substrate 7, and then the steps in Embodiment 1 are carried out (9)-step (11); this embodiment is the same as other steps in the preparation process of embodiment 1, and will no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com