Preparation method of gamma-Fe2O3-coated HAP magnetic composite material for removing uranium

A magnetic composite material and composite material technology, applied in the field of preparation of γ-Fe2O3@HAP magnetic composite material, can solve the problems of unconsidered material disposal, environmental secondary pollution, complex preparation process of adsorption or removal agent, and inability to recycle and use, etc. problems, to achieve excellent purification effect, fast adsorption speed, and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A method for preparing a γ-Fe2O3@HAP magnetic composite material for removing uranium, comprising the following steps:

[0039] Step 1, weigh 0.5392g γ-Fe 2 o3 Disperse in 20mL ethylene glycol, then add 30mL water, stir evenly to form magnetic levitation solution A;

[0040] Step 2, weigh 7.9583g (33.7mmol) of Ca(NO 3 ) 2 4H 2 O was dissolved in 100mL deionized water, and stirred evenly to form solution B;

[0041] Step 3: Mix the magnetic levitation solution A with the solution B, stir evenly and adjust the pH to 11 with diluted ammonia solution;

[0042] Step 4, weigh 2.6412g (20mmol) of (NH 4 ) 2 HPO 4 Dissolve in 50mL deionized water, stir evenly and add dropwise to the mixed solution prepared in step 3 with a burette;

[0043] Step 5, place the mixed solution prepared in step 4 in an oil bath at 90°C for 4 hours, take it out and age it overnight;

[0044] Step 6, obtain the solid by solid-liquid separation, wash it several times with deionized water and ab...

example 1

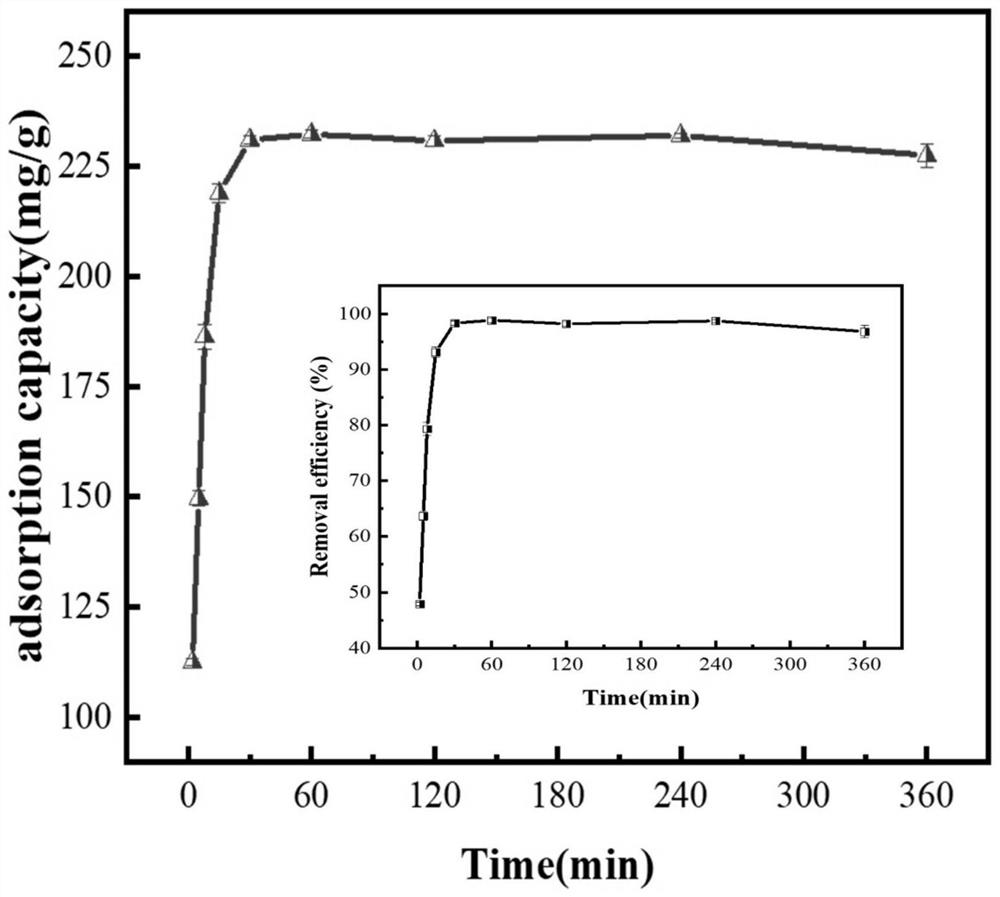

[0046] With the gamma-Fe that embodiment 1 makes 2 o 3 The @HAP composite material is used as a sample to determine the relationship between uranium adsorption performance and adsorption time, including the following steps:

[0047] Step 1: Prepare 50 mL of uranium solution with an initial concentration of 50 mg / L, and adjust the pH of the solution to 4.

[0048] Step 2: Add 0.0125 g of the adsorbent prepared in Example 1 to the solution in Step 1, shake the reaction at room temperature, take samples at different times, and filter the water samples for later use.

[0049] In step 3, the concentration of uranium in the water sample obtained in step 2 is detected by spectrophotometry, and the adsorption capacity of the adsorbent at different equilibrium concentrations is calculated. see attached results figure 1 .

[0050] The detection result of the present embodiment is: the gamma-Fe that embodiment 1 prepares 2 o 3 The adsorption of uranium by the @HAP composite materia...

) example 2

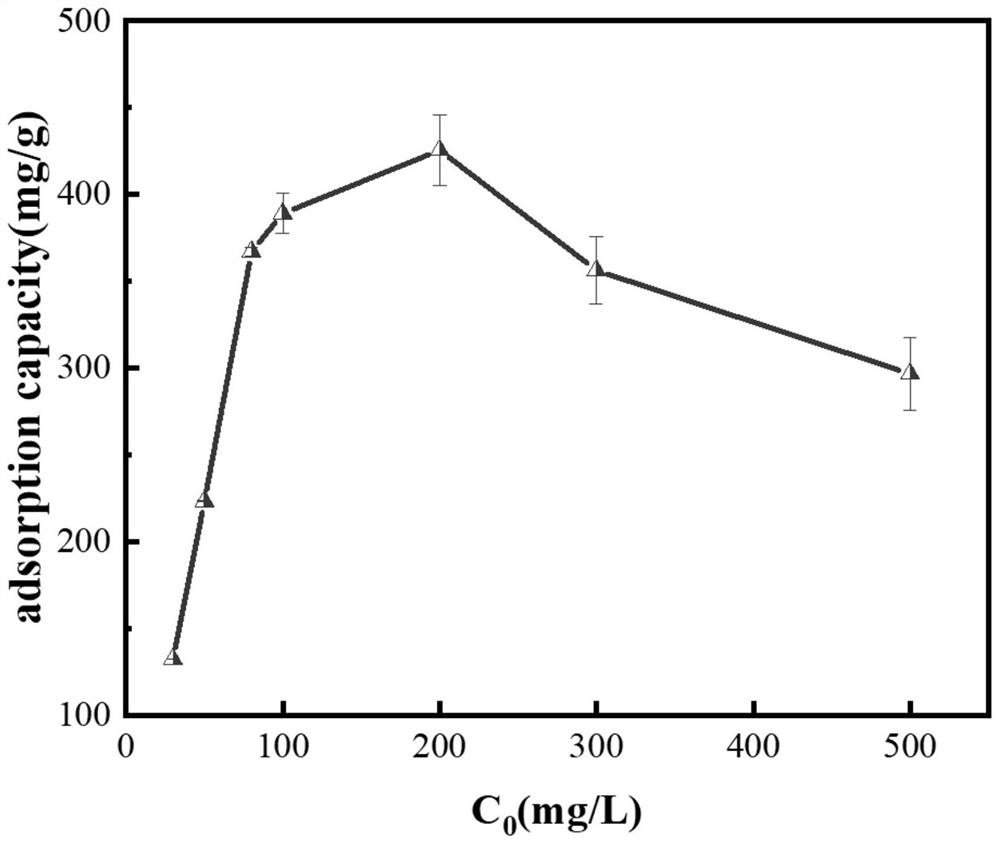

[0052] With the gamma-Fe that embodiment 1 makes 2 o 3 The @HAP composite material is used as a sample to measure the adsorption capacity under different concentrations of uranium, including the following steps:

[0053] Step 1, prepare 50 mL of uranium solutions with concentration gradients of 30, 50, 80, 100, 200, 300 and 500 mg / L and initial concentration pH=4.

[0054] Step 2: Add 0.0125 g of the adsorbent prepared in Example 1 to the solution in Step 1, shake and react at room temperature, take a sample after the reaction reaches equilibrium, and filter the water sample for later use.

[0055] In step 3, the concentration of uranium in the water sample obtained in step 2 is detected by spectrophotometry, and the adsorption capacity of the adsorbent at different equilibrium concentrations is calculated. see attached results figure 2 .

[0056] The detection result of the present embodiment is: the gamma-Fe that embodiment 1 prepares 2 o 3 The maximum adsorption capa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com