Preparation method of high-ductility cement-based composite material

A composite material and cement-based technology, applied in the field of high ductility cement-based composite material preparation, can solve the problems of spalling and crushing, prone to brittle failure, low concrete tensile strength, etc., achieve good impact resistance and seismic characteristics, reduce settlement deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

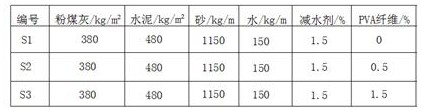

Embodiment 1

[0019] A method for preparing a high-ductility cement-based composite material, the steps are as follows:

[0020] Step 1: Add 480kg / m 2 Cement, 380kg / m 2 The fly ash and 1150kg / m sand are mixed and stirred evenly to obtain the mixture;

[0021] Step 2: Pour 1.5% water reducer into 150kg / m water and stir for 3-5 minutes. After the two are evenly dissolved, pour into the mixture and stir until it is in a fluid plastic state, then stop to obtain a wet mixture;

[0022] Step 3: Put the wet mixture in a model of 40mm*40mm*160mm, place the model on a vibrating device, vibrate and compact it, then let it stand for 24 hours, and then standardize it for 28 days to obtain a high-ductility cement-based composite material.

Embodiment 2

[0024] A method for preparing a high-ductility cement-based composite material, the steps are as follows:

[0025] Step 1: Add 480kg / m 2 Cement, 380kg / m 2 The fly ash and 1150kg / m sand are mixed and stirred evenly to obtain the mixture;

[0026] Step 2: Pour 1.5% water reducer into 150kg / m water and stir for 3-5 minutes. After the two are evenly dissolved, pour into the mixture and stir until it is in a fluid plastic state, then stop to obtain a wet mixture;

[0027] Step 3: Sprinkle 0.5% PVA fiber evenly into the wet mixture, and keep stirring until it is evenly fused to obtain the mixture;

[0028] Step 4: Put the mixture in a model of 40mm*40mm*160mm, place the model on a vibrating device, vibrate and compact it, then let it stand for 24 hours, and then standardize it for 28 days to obtain a superelastic SMA reinforced high ductility cement-based composite Material.

Embodiment 3

[0030] A method for preparing a high-ductility cement-based composite material, the steps are as follows:

[0031] Step 1: Add 480kg / m 2 Cement, 380kg / m 2 The fly ash and 1150kg / m sand are mixed and stirred evenly to obtain the mixture;

[0032] Step 2: Pour 1.5% water reducer into 150kg / m water and stir for 3-5 minutes. After the two are evenly dissolved, pour into the mixture and stir until it is in a fluid plastic state, then stop to obtain a wet mixture;

[0033] Step 3: Sprinkle 1.5% PVA fiber evenly into the wet mixture, and keep stirring until it is evenly fused to obtain the mixture;

[0034] Step 4: Put the mixture in a model of 40mm*40mm*160mm, place the model on a vibrating device, vibrate and compact it, then let it stand for 24 hours, and then standardize it for 28 days to obtain a superelastic SMA reinforced high ductility cement-based composite Material.

[0035] The overall performance of the high-ductility cement-based composite material in the above examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com