Method for treating salt-containing wastewater

A technology for saline wastewater and edible salt, applied in chemical instruments and methods, multi-stage water/sewage treatment, biological water/sewage treatment, etc., can solve problems such as high operating costs and achieve cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1. Isolation, purification and identification of Dunaliella salina and symbiotic bacteria

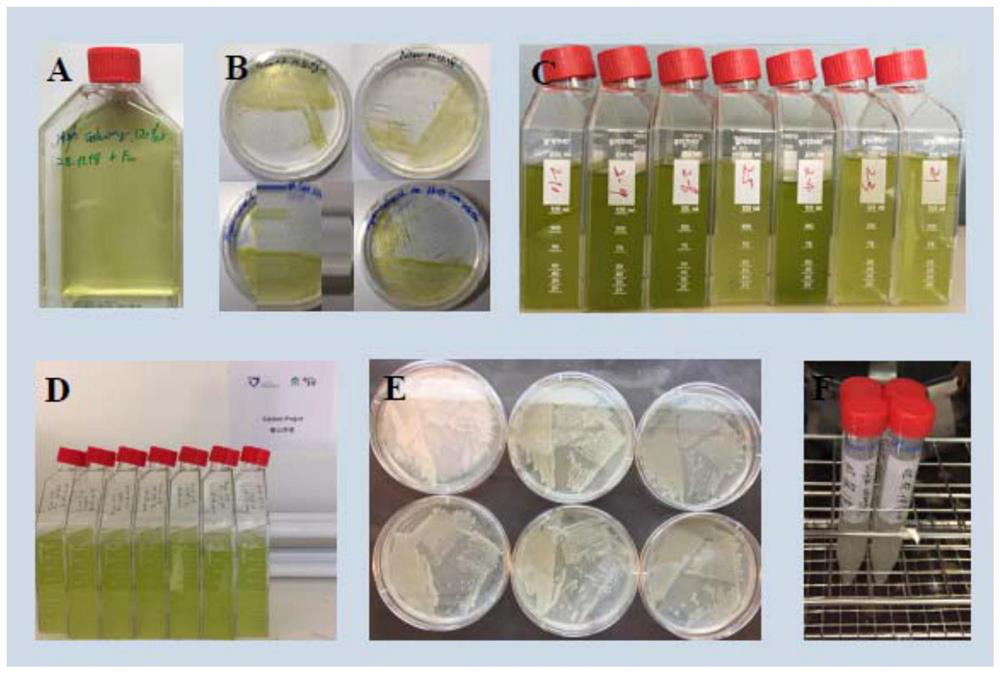

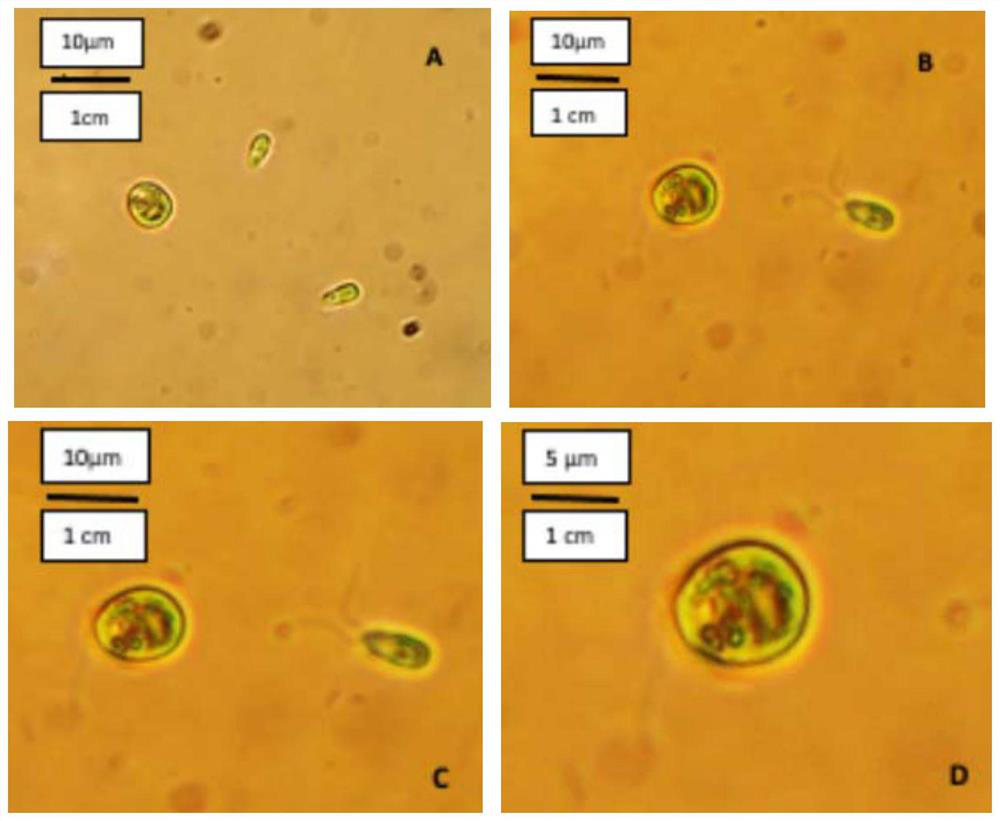

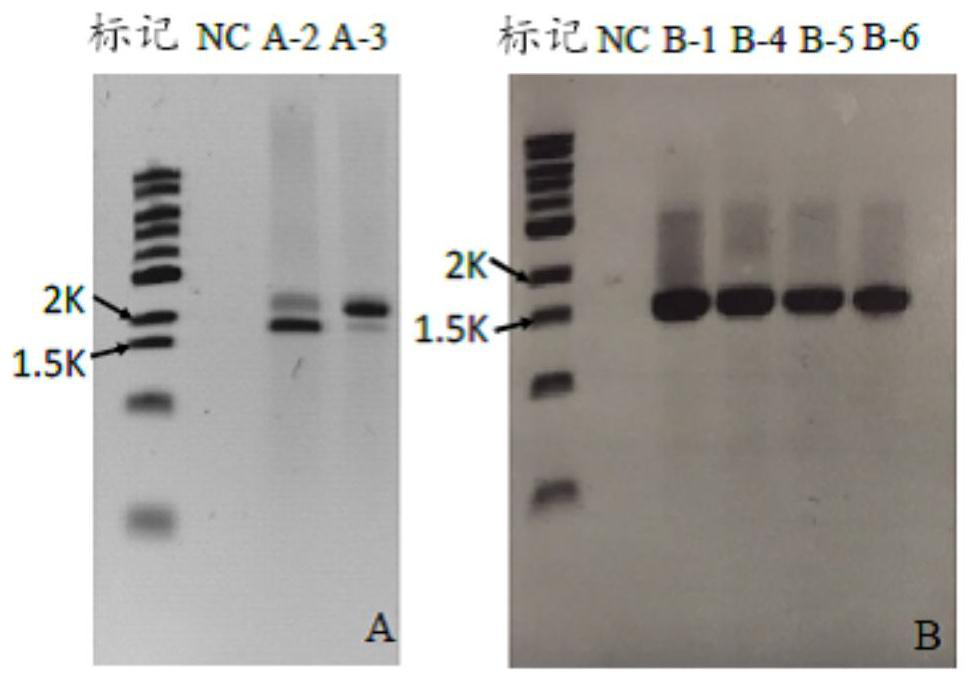

[0075] Isolation and purification of Dunaliella salina: The salinity of the kelp production and processing water sampled by Haizhibao Company and brought back to Jacobs University Bremen is close to 20%. After adding twice the f / 2 (Guillard 1975) medium nutrient salt to the sampled processing water, place it in a temperature-controlled room at 21±1°C for cultivation. After one month of cultivation, the concentration of microalgae cells in the sample increased significantly compared with the initial colorless water sample, as shown in figure 1 As shown in A. Spread an integer volume of algae liquid evenly on an agar plate supplemented with twice the f / 2 nutrient salt and cultivate until the microalgae single colony of Dunaliella salina grows on the plate, such as figure 1Shown in B. Single colonies of microalgae are picked and transferred to separate culture flasks to f...

Embodiment 2

[0087] Embodiment 2: Batch cultivation of Dunaliella salina in universal medium with different salinities

[0088] Although Dunaliella salina is characterized by tolerance to high salinity, salinity may have an impact on wastewater treatment efficiency and carotenoid accumulation. Therefore, it is necessary to optimize the salinity of process water before using Dunaliella salina to treat process water. For this reason, in this example, the optimum salinity suitable for the processing water of Dunaliella salina was tested.

[0089] The culture conditions are as follows: use 4 times of f / 2 universal medium to cultivate Dunaliella salina, where: initial OD 725 The value is about 0.2; the salinity of the medium is adjusted by adding sodium chloride; the illumination is provided by a fluorescent tube: the light intensity is 200 μmol / m 2 / s; the light cycle is 14 hours light / 10 hours dark; the room temperature is maintained at 25±1°C; the pH is set to 7.4 and the hysteresis effect...

Embodiment 3

[0094] Example 3: Cultivation of Dunaliella salina in synthetic process water

[0095] According to the analysis report of the original saturated processing water provided by Haizhibao, the synthetic processing water is prepared to simulate the actual wastewater treatment situation. According to the information provided by Haizhibao, the water source for processing water is seawater. Therefore, in this experiment, in order to better simulate the actual water source that needs to be treated, North Sea seawater was used to prepare synthetic processing water in the laboratory. By adding sodium chloride To increase the salinity of seawater, add NH 4 Cl and KH 2 PO 4 as inorganic nutrients. The contents of nutrients and total organic carbon (TOC) in the prepared processing water with a salinity of 5%, 10% and 15% are shown in Table 2 below. Of course, it is understood that in order to achieve maximum nutrient recovery efficiency and biomass yield, the saturated process water ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com