Vacuum sizing spraying box for polyvinyl chloride pipe production line

A technology of vacuum sizing and polyvinyl chloride, which is applied in the field of vacuum sizing spray boxes for polyvinyl chloride pipe production lines, and can solve problems such as pipe deformation, yellowing, and surface oxidation of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

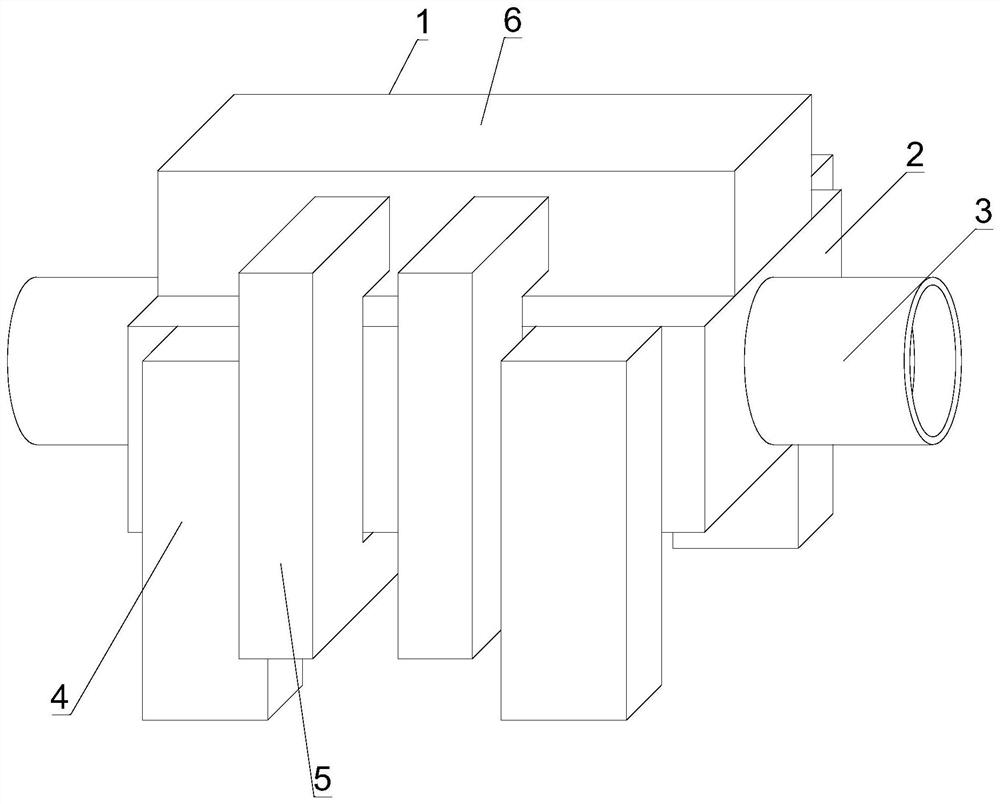

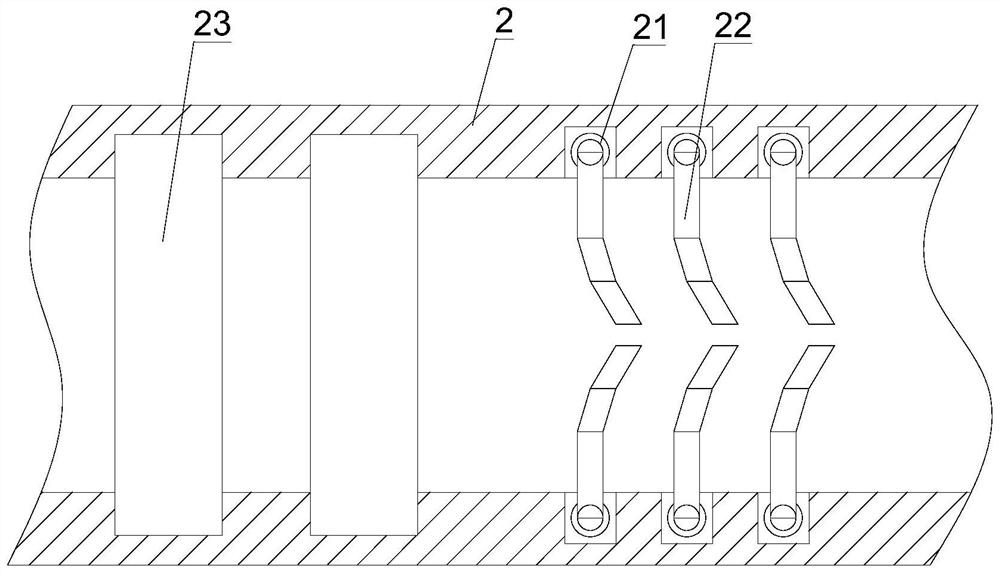

[0047] Such as Figure 1-9 As shown, the present invention provides a vacuum sizing spray box for a polyvinyl chloride pipe production line, including a polyvinyl chloride pipe vacuum sizing sprayer 1, and the polyvinyl chloride pipe vacuum sizing sprayer 1 includes a spray box 2. Rotation guides 3 are detachably installed on the outer surfaces of both sides of the spray box 2, and snap-in blocks 21 are detachably installed on the upper and lower inner surfaces of the right side of the spray box 2, and the outer surfaces of the snap-in blocks 21 Bending tube surface laminating device 22 is detachably installed on the top, vacuum extractor 23 is detachably installed on the upper and lower inner surfaces of the left side of spray box 2, and rotation guide 3 includes lifter 34, the lifter 34 A clamping rotator 35 is detachably installed on the outer surface, and a rotating wheel 36 is arranged on the inner and outer surfaces of the clamping rotator 35 .

[0048] In this embodime...

Embodiment 2

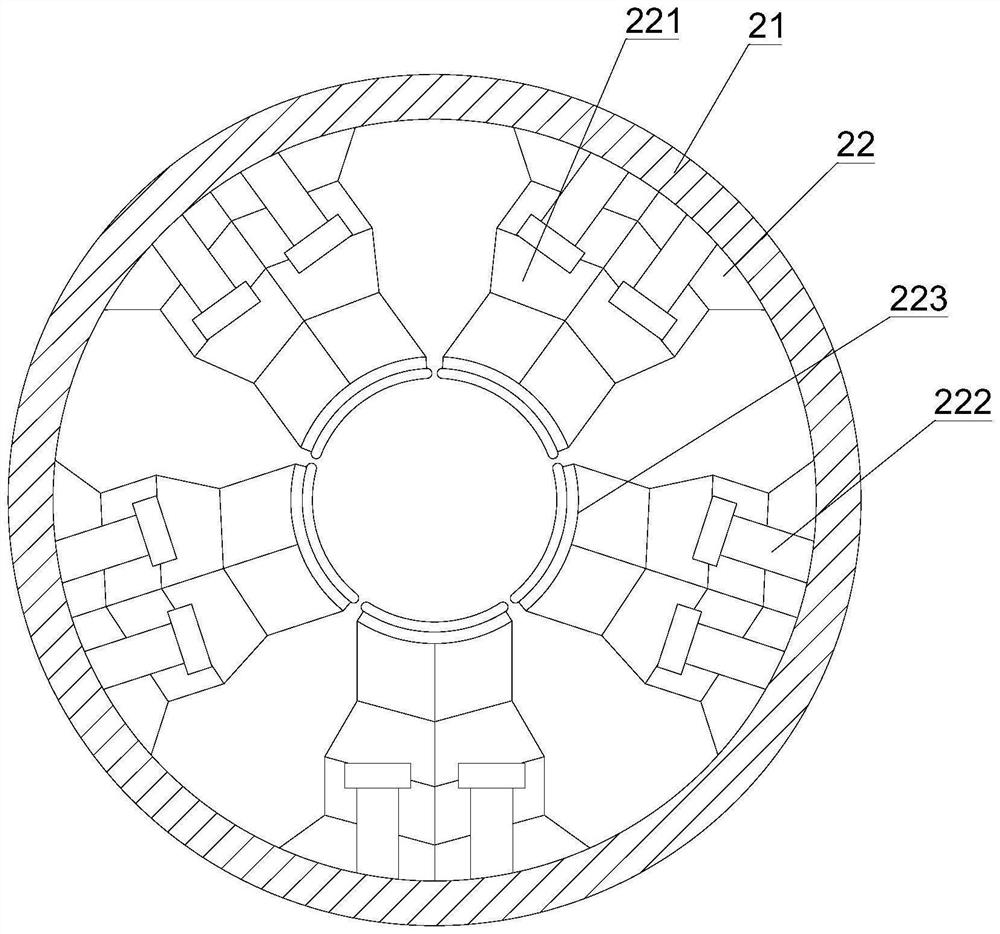

[0050] Such as Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the bent tube surface applicator 22 includes a folded and bent plate 221, and the outer surface of the outer bottom of the folded and bent plate 221 is detachably installed There is a water splash extractor 222, one end of the water splash extractor 222 extends to the outer surface of the clamping block 21, the shape of the folded and curved plate 221 gradually shrinks, and the folded and curved plate 221 is evenly distributed on the inner surface of the clamping block 21, One end of the folded and curved plate 221 is provided with a cleaning arc plate 223 .

[0051] The top outer surface of the fitting and cleaning arc plate 223 is detachably installed with an arc-shaped fitting soft board layer a1, and the outer surface of the arc-shaped fitting soft board layer a1 is provided with a high-pressure atomization water spray hole a2, and the high-pr...

Embodiment 3

[0054] Such as Figure 1-9 As shown, on the basis of Example 2, the present invention provides a technical solution: preferably, the outer surface of the bottom of the high-pressure atomization water spray hole a2 is provided with a water inlet pipe hole a21, and the two high-pressure atomization water spray holes a2 Auxiliary water guide pipe a22 is detachably installed on the side outer surface, and one end of auxiliary water guide pipe a22 is provided with atomization auxiliary nozzle a23, and the top of high-pressure atomization spray hole a2 is detachably connected with high-pressure atomizer head a24, A water-guiding atomizing bar a25 is arranged on the outer surface of the high-pressure atomizing head a24, and is arranged on the outer surface of the top end of the high-pressure atomizing head a24 and on both sides of one end of the water-guiding atomizing bar a25.

[0055] In this embodiment, the water source is directed to the inside of the high-pressure atomization wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com