Composite solid electrolyte and preparation method thereof

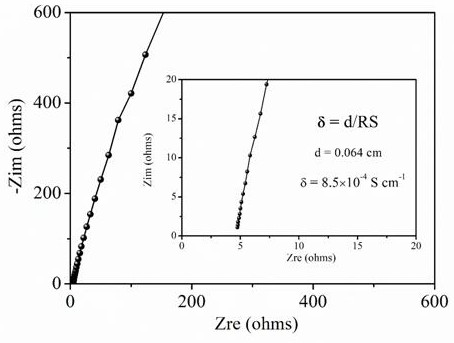

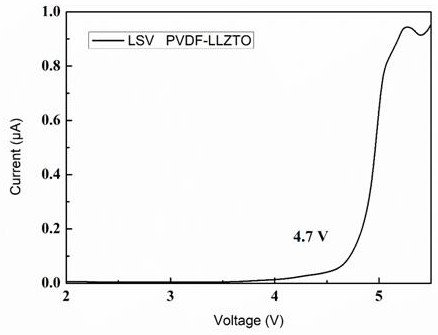

A solid electrolyte and polymer technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of reducing the crystallinity of PVDF polymers, affecting the film coating process, and low ionic conductivity at room temperature, achieving enhanced Effects of segment mobility, reduced crystallinity, and high room temperature ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A method for preparing a composite solid electrolyte, comprising the following steps:

[0039] (1) Under the protective atmosphere of the glove box, weigh the plasticizer, dispersant, lithium salt, fine Li6.75La3Zr1.75Ta0.25O12 ceramic powder and PVDF polymer substrate and add them to the reagent bottle; add the organic solvent to the In the above reagent bottle, the mixed solution is obtained, and then sealant is used to seal the mouth of the reagent bottle;

[0040] (2) Use a magnetic stirrer to fully stir the above mixed solution to dissolve the solute and mix evenly to obtain a glue; after that, heat the obtained glue in a water bath;

[0041] (3) Cast the glue solution on the polytetrafluoroethylene plate, use a scraper to scrape it to an appropriate thickness, then place it in a vacuum oven for drying to obtain a composite solid electrolyte membrane, and finally cut the solid electrolyte membrane to a suitable size. Composite solid electrolyte membrane.

[0042]...

Embodiment 1

[0049] A composite solid electrolyte and a preparation method thereof, comprising the following steps:

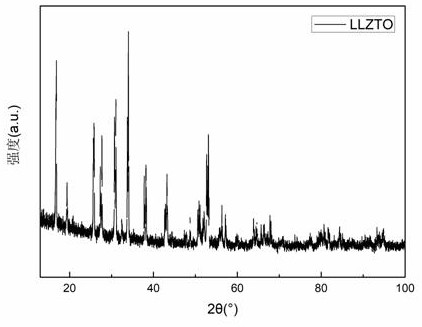

[0050] (1) Under the protective atmosphere of the glove box, weigh 0.3005g succinonitrile, 0.0963g polyvinylpyrrolidone, 1.0116g lithium bistrifluoromethanesulfonimide, 0.3065g fine LLZTO ceramic powder and 3.0291g polyvinylidene fluoride Chlorotrifluoroethylene copolymer is added to the reagent bottle, wherein the ratio of VDF and CTFE is 88%:12%; 30ml N, N-dimethylformamide is added to the above reagent bottle to obtain a mixed solution, and then use a sealed Seal the mouth of the reagent bottle with glue;

[0051] (2) Use a magnetic stirrer to fully stir the above mixed solution to dissolve the solute and mix evenly to obtain a glue solution. The stirring time is 12 hours; after that, the obtained glue solution is heated in a water bath for 6 hours and the heating temperature is 60°C ;

[0052] (3) Cast the glue solution on a polytetrafluoroethylene board, use a scrape...

Embodiment 2

[0054] A composite solid electrolyte and a preparation method thereof, comprising the following steps:

[0055] (1) Under the protective atmosphere of the glove box, weigh 0.6044g succinonitrile, 0.0163g polyacrylamide, 1.5072g lithium perchlorate, 0.9017g fine LLZTO ceramic powder and 3.0531g polyvinylidene fluoride chlorotrifluoroethylene copolymer and add it into the reagent bottle, wherein the ratio of VDF and CTFE is 92%:8%; add 30ml N,N-dimethylformamide into the above reagent bottle to obtain a mixed solution, and then seal the reagent bottle with sealant mouth;

[0056] (2) Use a magnetic stirrer to fully stir the above mixed solution to dissolve the solute and mix evenly to obtain a glue solution. The stirring time is 6 hours; after that, the obtained glue solution is heated in a water bath for 3 hours and the heating temperature is 40°C. ;

[0057] (3) Cast the glue on the polytetrafluoroethylene board, use a scraper to scrape it to an appropriate thickness, then p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com