Anti-vulcanization bonding silver wire

A technology of anti-vulcanization and vulcanization bond, which is applied in the direction of coating, wax coating, circuit, etc., can solve the problems of lack of luster, increase of cost, and influence on the popularization and application of bonding silver wire, so as to improve reliability, good heat insulation, Good anti-vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

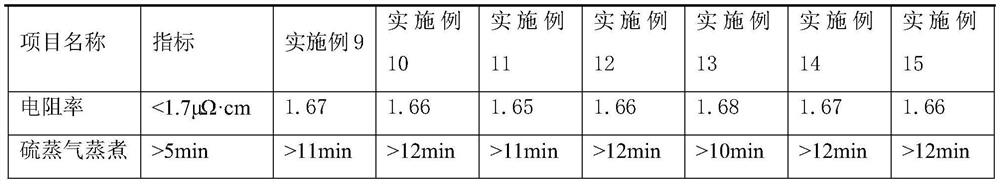

Examples

Embodiment 1

[0021] An anti-sulfur bonding silver wire, the surface of the bonding silver wire is coated with an anti-sulfur coating.

[0022] The bonding silver wire of the present invention realizes anti-corrosion and anti-sulfurization effects through the anti-sulfurization coating, and improves the reliability of the bonding silver wire.

Embodiment 2

[0024] Compared with Example 1, the anti-sulfur coating includes the following components in weight percentage: rosin 1%, epoxy resin 24%, ozokerite 25%, polystyrene 50%.

Embodiment 3

[0026] Compared with Example 1, the anti-sulfur coating includes the following components in weight percentage: rosin 25%, epoxy resin 25%, ozokerite 20%, polystyrene 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com