Fructus cannabis functional polypeptide and preparation method thereof

A hemp seed and multi-functional technology, which is applied in the field of hemp seed functional polypeptide and its preparation, can solve the undisclosed problems of inhibiting the activity of α-amylase and lipase, and achieve the improvement of low utilization rate of raw materials, low utilization rate of raw materials, and the like. The effect of increasing yield and reducing processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

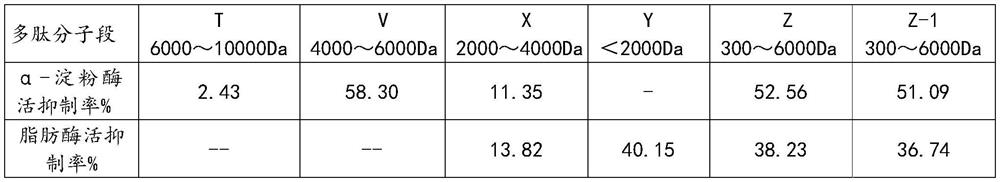

Examples

Embodiment 1

[0033] S100. Hemp seed cake pretreatment: Take 1000 grams of defatted hemp seed meal powder crushed to 80-100 mesh (containing 70% protein), add 20 kg of water, stir well, boil for 4 minutes, pour into a colloid mill and circulate for grinding for 3 minutes , forming the hemp seed meal liquid;

[0034] S200, the first enzymatic hydrolysis: use hydrochloric acid solution to adjust the pH of the hemp seed meal liquid to 2.6; add 3.4310 acid protease 3.2 million u, hydrolyze at 45°C for 130min; after the hydrolysis, inactivate the enzyme at 80°C for 8min to obtain the first enzymatic solution;

[0035] S300, the second enzymatic hydrolysis: After the first enzymatic hydrolysis liquid is cooled, add 2.8 million u of pepsin, and hydrolyze it for 50 minutes under the conditions of pH 2.2 and 37°C; Obtain the second enzymolysis solution;

[0036] S400, sediment enzymolysis: centrifuge the second enzymolysis solution at 4000rpm for 10min with a centrifuge to obtain supernatant A and...

Embodiment 2

[0045] S100. Pretreatment of hemp seed meal: take 100 grams of defatted hemp seed meal powder crushed to 80-100 mesh (containing 70% protein), add 2 kg of water, stir well, boil for 3 minutes, pour into a colloid mill and circulate for grinding for 3 minutes , forming the hemp seed meal feed liquid.

[0046] S200, the first enzymatic hydrolysis: adjust the pH of the hemp seed meal liquid to 3.0 with citric acid solution, add 3.4310 acid protease 350,000 u, hydrolyze at 48°C for 90 minutes; after the hydrolysis is completed, inactivate the enzyme at 90°C 5min to obtain the first enzymatic hydrolysis solution.

[0047] S300, the second enzymatic hydrolysis: after the first enzymatic hydrolysis solution is cooled, add 245,000 u of pepsin, and hydrolyze it for 45 minutes at a pH of 2.5 and 40°C; after the hydrolysis, heat to 85°C to inactivate the enzyme for 3 minutes Obtain the second enzymolysis solution.

[0048] S400, sediment enzymolysis: centrifuge the second enzymolysis l...

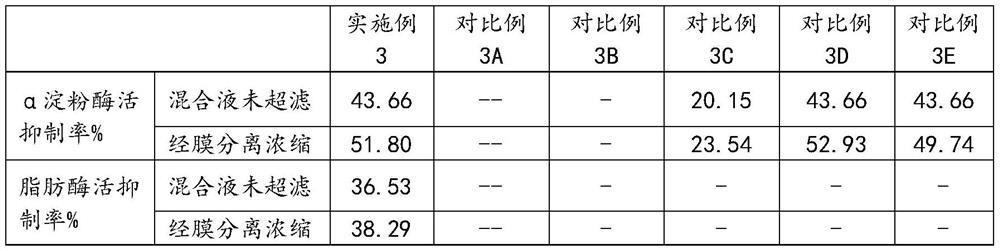

Embodiment 3

[0057] S100. Hemp seed cake pretreatment: Take 100 grams of defatted hemp seed meal powder crushed to 80-100 mesh (containing 70% protein), add 2 kg of water, stir well, boil for 3 minutes, pour into a colloid mill and circulate for grinding for 3 minutes , forming the hemp seed meal liquid;

[0058] S200, the first enzymatic hydrolysis: use hydrochloric acid solution to adjust the pH of the hemp seed meal liquid to 3.2; add 3.4310 acid protease 420,000 u, and hydrolyze at 52°C for 70 minutes; after the hydrolysis, extinguish the enzyme at 85°C for 8 minutes to obtain the first One enzymatic solution;

[0059] S300, the second enzymatic hydrolysis: After the first enzymatic hydrolysis solution is cooled, add 180,000 u of pepsin, and hydrolyze it for 30 minutes at pH 2.8 and 42°C; after hydrolysis, heat to 85°C to inactivate the enzyme for 3 minutes, Obtain the second enzymolysis solution;

[0060] S400, sediment enzymatic hydrolysis: centrifuge the second enzymatic hydrolysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com