Method for improving fermentation yield and conversion rate of threonine

A technology for increasing threonine and conversion rate, which is applied in the field of threonine fermentation, can solve problems such as impact, and achieve the effects of high efficiency, simple process operation, high stability and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

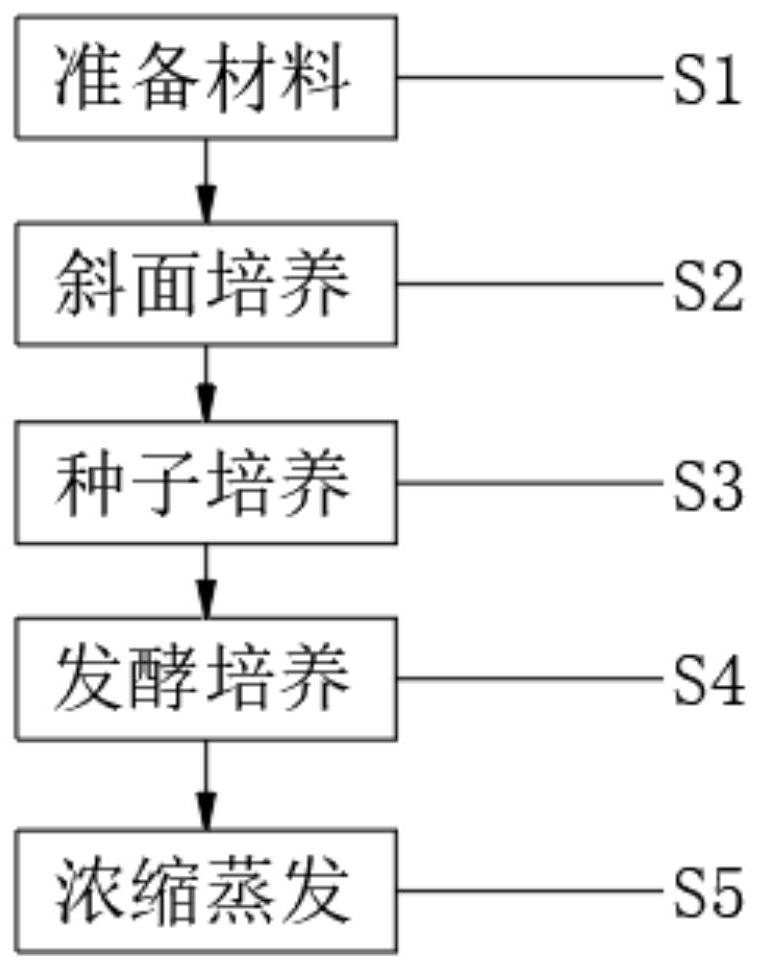

[0034] A method for increasing threonine fermentation yield and conversion rate, comprising the following steps:

[0035] S1. Preparation materials: Prepare 5.0% glucose, 1.5% peptone, 1.5% yeast powder, 1.5% beef extract, 1.0% NaCl, 2.0% agar, 0.55% KH2PO4, 0.25% MgSO4, 30mg / L FeSO4, 25mg / L MnSO4 , corn steep liquor 4.5%, VB14mg / L, amino acid powder 1.1%, paodi 0.005%, betaine 0.2%, choline 0.2%;

[0036] S2, slant culture: take 0.2% glucose, 1.0% peptone, 0.5% yeast powder, 1.0% beef extract, 0.5% NaCl, 1.8% agar, put it into the slant medium, adjust the pH value to 7.2, and Put the slant medium into the heating box, adjust the temperature to 36°C, and cultivate for 20 hours. After passing the inspection, put it in the refrigerator for future use;

[0037] S3. Seed culture: use glucose 3.0%, KH2PO40.15%, MgSO40.05%, FeSO410mg / L, MnSO410mg / L, corn steep liquor 2.5%, yeast powder 0.30%, VB12mg / L, amino acid powder 0.5%, bubble enemy 0.002%, put it into the seed medium, adjus...

Embodiment 2

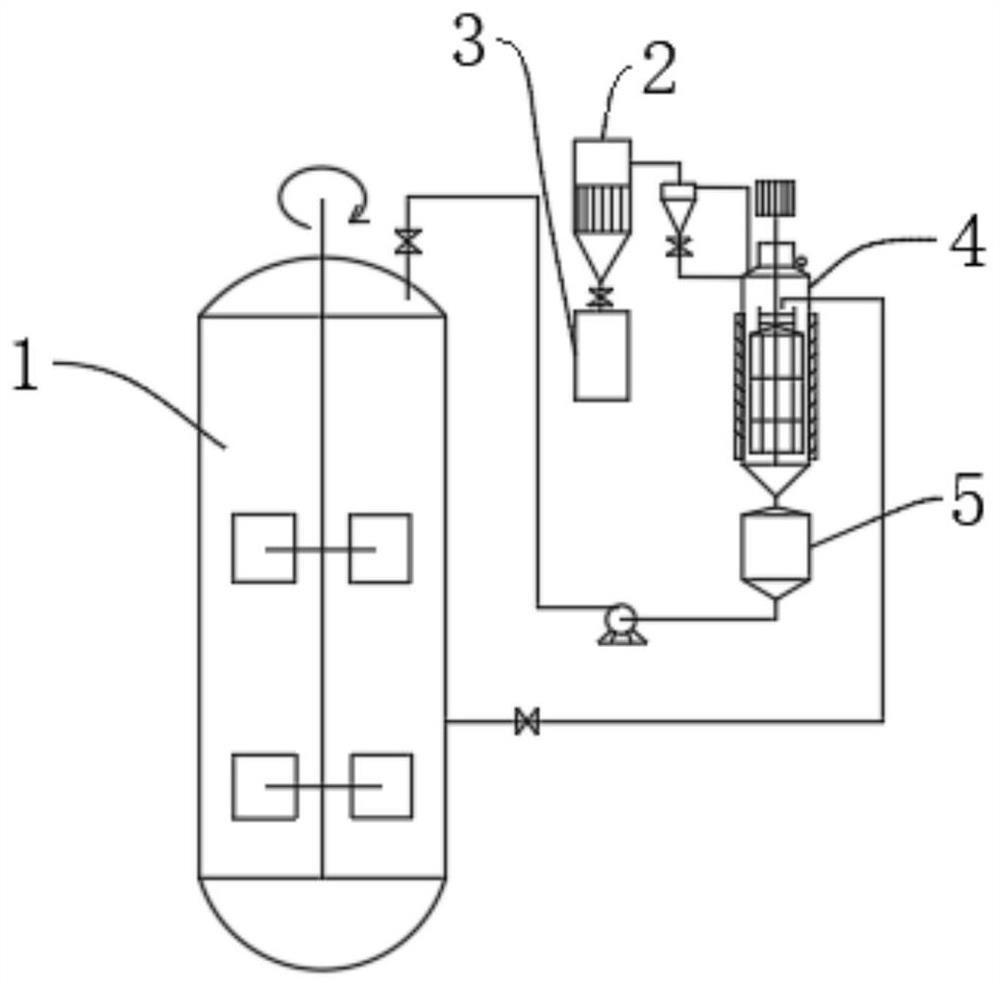

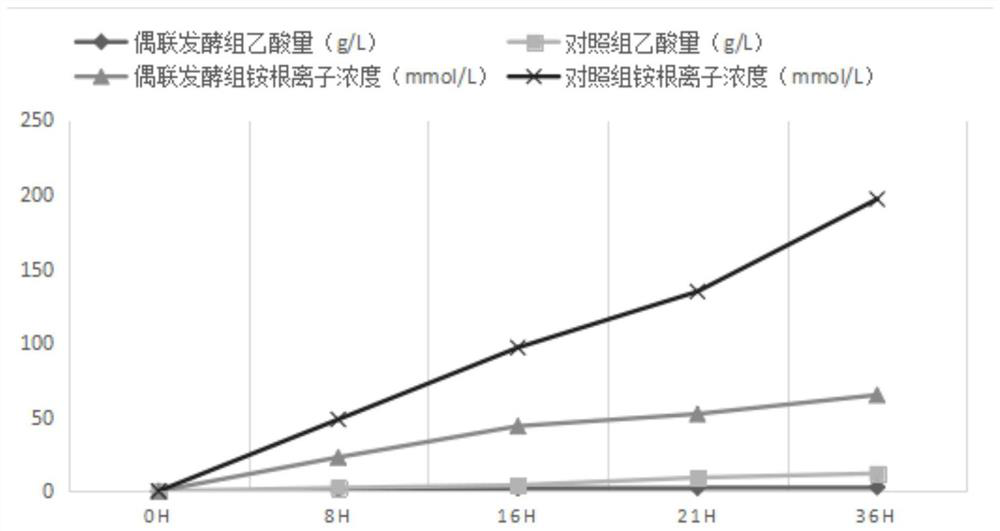

[0042] When L-threonine is fermented to 16 hours, use the scraper concentration and evaporation system to carry out vacuum evaporation to remove acetic acid and NH4+ in the fermentation broth. The concentrated fermentation broth is pressed into the fermentation tank by a diaphragm pump to continue fermentation, and the evaporation is replenished with sterile water. After 16 hours of evaporation, the acetic acid in the coupling fermentation has been maintained at a low level in the middle and late stages of the fermentation. At the end of the fermentation, the acetic acid was 2.7g / L, while the fermentation acetic acid in the control group was 9.2g / L , the concentration of acetic acid decreased by 70.65%, and the concentration of ammonium ion decreased from 132.0mmol / L in the control fermentation to 52.9mmol / L in the coupled fermentation, a decrease of 59.92%. The amount of bacteria in the coupled fermentation maintained a rapid growth trend. At 36 hours of fermentation, the OD60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com