Nanometer flaky MFI molecular sieve and preparation method thereof

A nano-sheet, molecular sieve technology, applied in the field of molecular sieves, can solve problems such as lack of crystal face selectivity, and achieve the effects of low production cost, uniform heating and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides a kind of preparation method of nano sheet MFI molecular sieve, comprises the following steps:

[0034] Mix the silicon source, tetrapropylammonium hydroxide and water, conduct microwave heat treatment, and then dialysis and purify to obtain the MFI crystalline solution;

[0035] The MFI crystalline solution is subjected to hydrothermal treatment to obtain nanosheet MFI molecular sieves.

[0036] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0037] The invention mixes the silicon source, tetrapropylammonium hydroxide and water, conducts microwave heat treatment, and then dialysis and purifies to obtain the MFI crystalline solution.

[0038] In the present invention, the silicon source preferably includes one or more of tetraethyl orthosilicate, silica sol and white carbon black, more preferably tetraethyl orthosilicate or sili...

Embodiment 1

[0055] (1) tetrapropyl ammonium hydroxide is dissolved in water and is mixed with the tetrapropyl ammonium hydroxide aqueous solution that concentration is 20wt%; 3g tetraethyl orthosilicate is dissolved in the 6.1686g tetrapropyl ammonium hydroxide aqueous solution, in Stir and age at room temperature and 150 rpm for 24 hours, then transfer to a microwave reactor, first heat-treat with low-temperature microwave at 90°C for 90 minutes, and then heat-treat with high-temperature microwave at 130°C for 50 minutes to obtain a mixed solution of MFI zeolite. The MFI zeolite mixed solution was transferred to a cellulose semi-permeable membrane with a molecular weight cut-off of 3.5kDa, then soaked in 1L of tetrapropylammonium hydroxide aqueous solution with a concentration of 6mmol / L, purified by dialysis at room temperature and 30rpm for 24h, and then Place in deionized water for dialysis purification, and replace the deionized water every 12 hours until the pH of the dialyzed fluid ...

Embodiment 2

[0061] According to the method of Example 1, the nano-flaky MFI molecular sieve is prepared, and the difference from Example 1 is only that in step (2), the pH of the MFI crystallization solution is adjusted to 11.41 by using an aqueous sodium hydroxide solution with a concentration of 1mol / L. , and then placed in a hydrothermal reaction kettle, the crystals were hydrothermally treated in a constant temperature oven for 18 hours; the centrifugal speed was 15000 rpm, and the centrifugal time was 5 minutes.

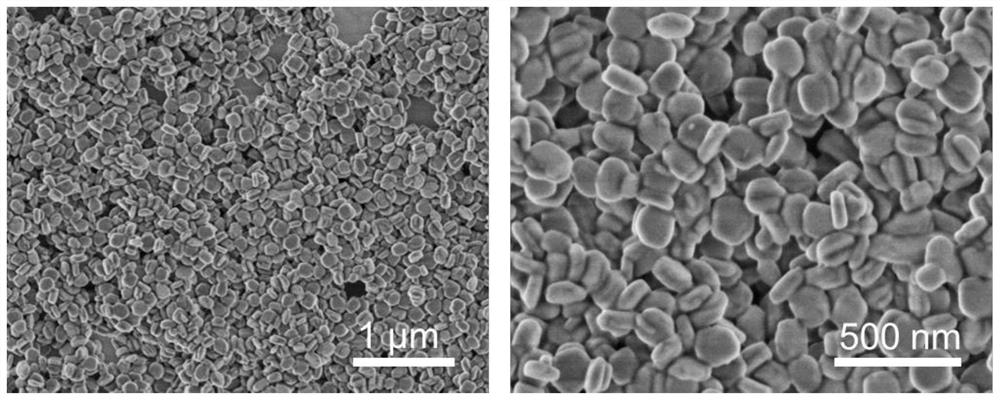

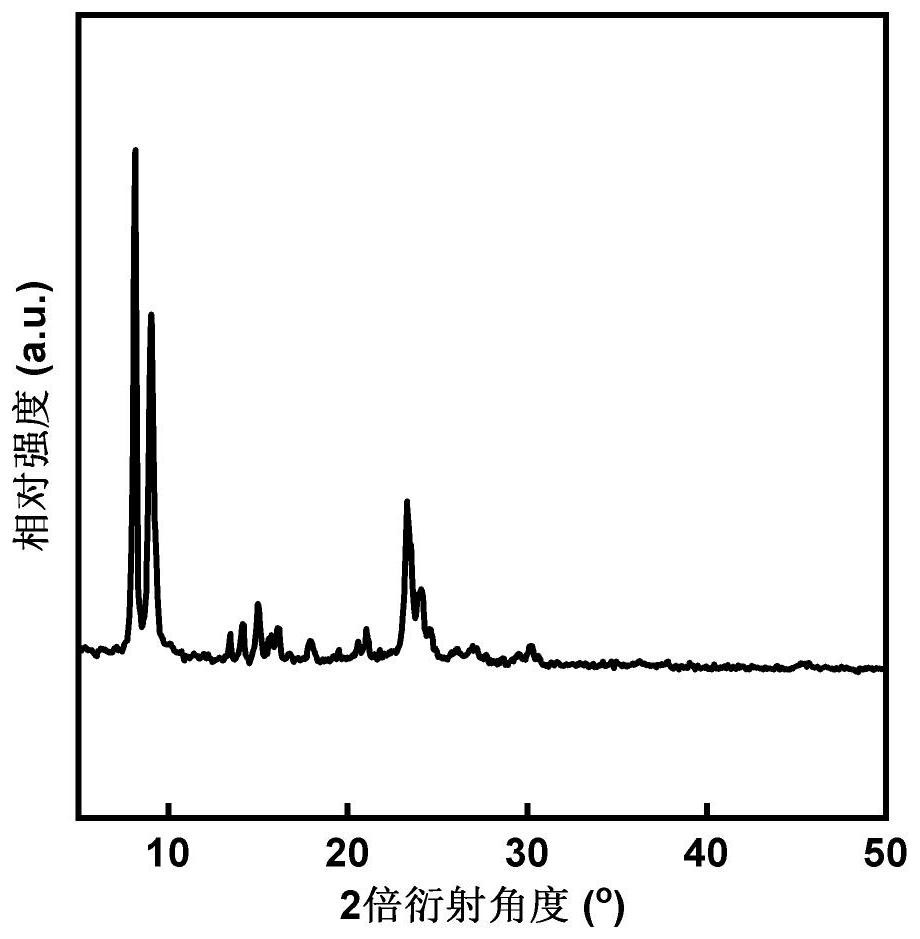

[0062] Figure 4 Scanning electron microscope image of the nanosheet MFI molecular sieve prepared for this example. Depend on Figure 4 It can be seen that the length × width × thickness of the nano-flaky MFI molecular sieve crystal obtained in this example is 160nm × 160nm × 80nm, which is a nano-flaky MFI molecular sieve crystal in the short b-axis direction with high crystal plane selectivity, and has good size uniformity .

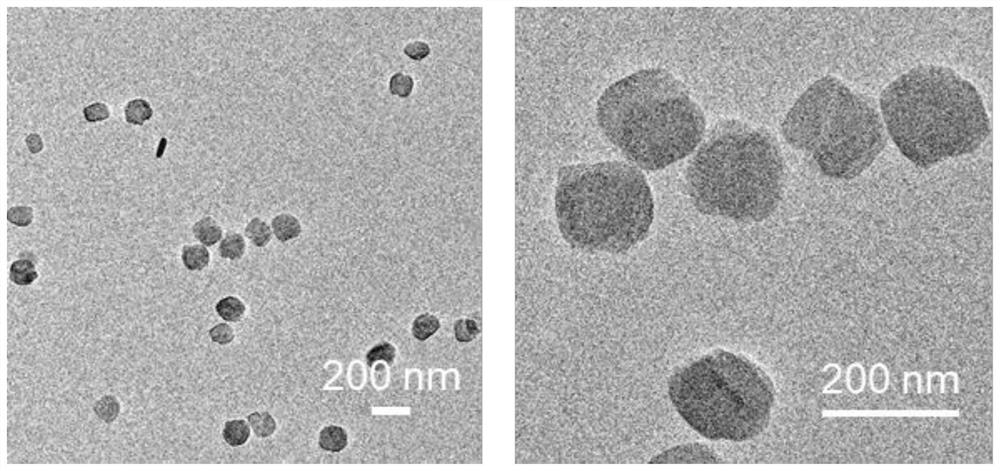

[0063] Figure 5 Transmission electron mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com