Cable construction conveying guide structure

A technology for guiding structures and cables, applied in the directions of transportation and packaging, transportation of filamentous materials, cleaning methods using tools, etc., can solve the problems of cable waste, corroded cables, shortened cable life, etc. The effect of cleaning, improving construction efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

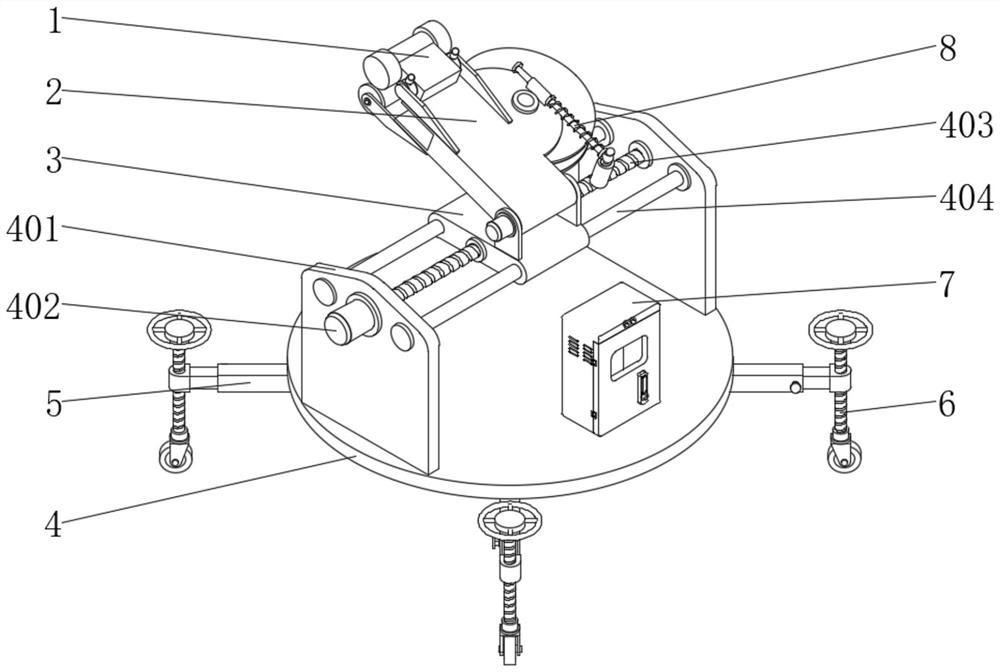

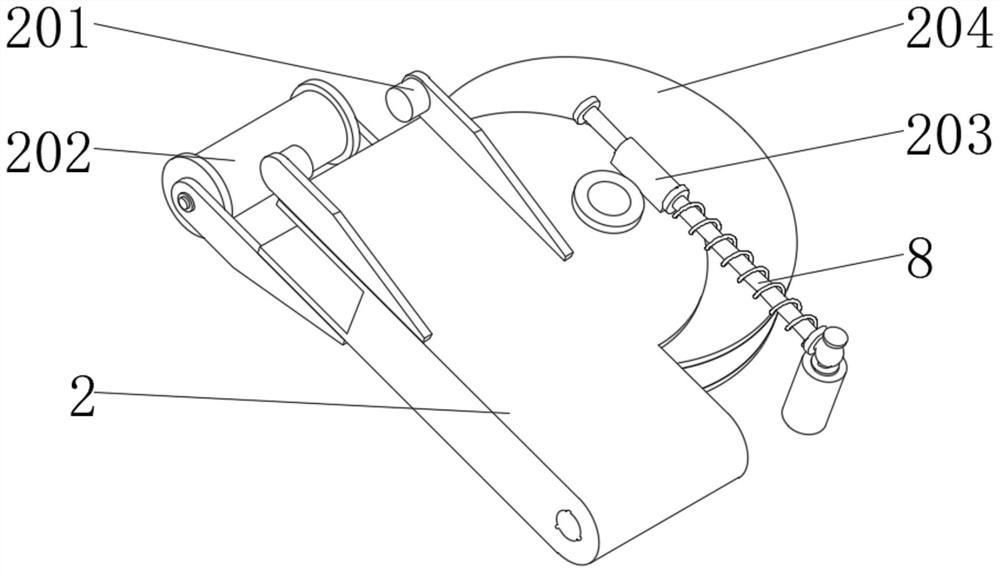

[0031] Such as Figure 1-7 As shown, a cable construction conveying guide structure proposed by the present invention includes an angle adjustment frame 2, a mounting plate 4 and a cleaning assembly 8, mounting plates 401 are installed on both sides of the top of the mounting plate 4, and a mounting plate 401 is installed on one side of the mounting plate 401. Servomotor 402, one side of servomotor 402 is installed with threaded rod 403 that runs through mounting plate 401, and the outside of threaded rod 403 is installed with moving seat 3 through threaded sleeve 302, and the top both sides of moving seat 3 is equipped with side plate 303, side The inboard of plate 303 is equipped with transmission rod 305, and the outside of transmission rod 305 is installed with angle adjustment frame 2 by card hole, and angle adjustment frame 2 top is installed with installation frame 201, and the inside of angle adjustment frame 2 is equipped with wire roulette 204, angle A sleeve 203 is ...

Embodiment 2

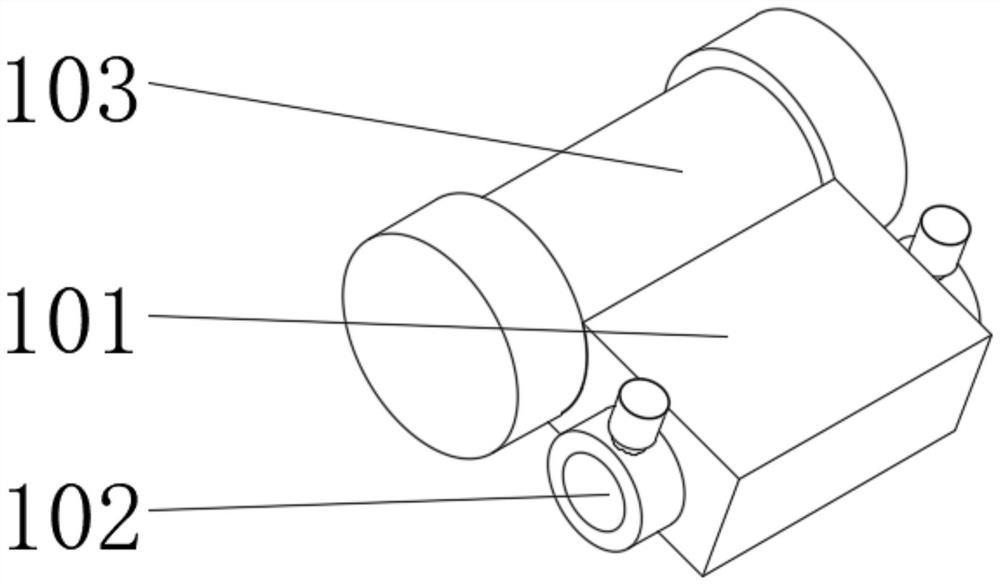

[0034] Such as Figure 2-6 As shown, the present invention proposes a guiding structure for cable construction. Compared with Embodiment 1, this embodiment also includes: mounting sleeves 102 are installed on both sides of the encoder 101, and the top of the mounting sleeve 102 is threaded. The knob is fixed, the limit runner 202 is installed on the bottom of the angle adjustment frame 2, and the inside of the angle adjustment frame 2 is provided with clamping holes, the inner sides of the moving seat 3 are provided with sliding holes 301, and the inside of the moving seat 3 is provided with threads Sleeve 302, a servo motor 304 is installed on one side of the side plate 303, and the output end of the servo motor 304 is connected with one end of the transmission rod 305, and two sets of sliding rods 404 are installed on one side of the mounting plate 401, and the sliding rods 404 move through Inside the seat 3, a sleeve rod 501 is installed in the extension frame 5, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com