Reusable polyurethane transfer film and preparation method thereof

A transfer film and polyurethane technology, applied in the field of polyurethane transfer film and its preparation, can solve the problems of polyurethane residue and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

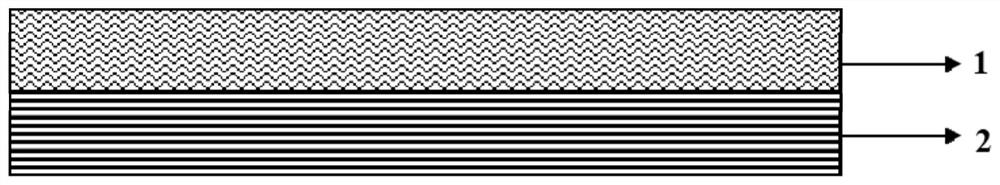

[0048] The film of this embodiment includes a layer of optical surface transfer layer 1 and a layer of support layer 2, wherein the optical surface transfer layer 1 is arranged on one side of the support layer 2, the side is the upper side or the lower side, the specific structure like figure 1 shown.

[0049] The composition of smooth transfer layer 1 is: 99.9wt% polymethylpentene copolymer (melt index is 4.6g / 10min, test conditions: melting temperature is 230°C, load weight is 2.16Kg), 0.1wt% synthetic silica , wherein the average particle size of synthetic silica is 4 μm. The polymethylpentene copolymer is the TPX produced by Mitsui Chemicals TM Polymethylpentene copolymer (the content of 4-methyl-1-pentene in the polymethylpentene copolymer is 95-100wt%, and its surface tension is 24mN / m).

[0050] Support layer 2 composition is: 97.2wt% homopolypropylene (isotacticity is 96%, melt index is 2.8g / 10min, melt index test condition: melting temperature is 230 ℃, load weight...

Embodiment 2

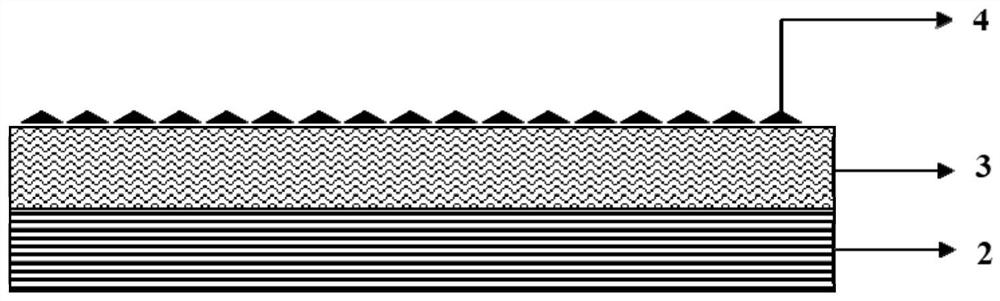

[0055] The film of this embodiment includes one layer of matt transfer layer 3 and one layer of support layer 2, wherein said matt transfer layer 3 is arranged on one side of support layer 2, said side is the upper side or the lower side, and the specific structure is as follows figure 2 shown.

[0056] The composition of the matting transfer layer 3 is: 95wt% polymethylpentene copolymer (melt index is 4.6g / 10min, test conditions: melting temperature is 230°C, load weight is 2.16Kg), 5wt% synthetic silica, wherein The average particle diameter of silica is 4 μm. The polymethylpentene copolymer is the TPX produced by Mitsui Chemicals TM Polymethylpentene copolymer (the content of 4-methyl-1-pentene in the polymethylpentene copolymer is 95-100wt%, and its surface tension is 24mN / m).

[0057] Supporting layer 2 composition is: 97.2wt% homopolypropylene (isotacticity is 96%, melt index is 2.8g / 10min, melt index test condition: melting temperature is 230 ℃, load weight is 2.16Kg...

Embodiment 3

[0061] The film of this embodiment includes one layer of matt transfer layer 3 and one layer of support layer 2, wherein said matt transfer layer 3 is arranged on one side of support layer 2, said side is the upper side or the lower side, and the specific structure is as follows figure 2 shown.

[0062] The composition of the matting transfer layer 3 is: 85wt% polymethylpentene copolymer (melt index is 4.6g / 10min, test conditions: melting temperature is 230°C, load weight is 2.16Kg), 15wt% synthetic silica, wherein The average particle diameter of silica is 4 μm. The polymethylpentene copolymer is the TPX produced by Mitsui Chemicals TM Polymethylpentene copolymer (the content of 4-methyl-1-pentene in the polymethylpentene copolymer is 95-100wt%, and its surface tension is 24mN / m).

[0063] Supporting layer 2 composition is: 97.2wt% homopolypropylene (isotacticity is 96%, melt index is 2.8g / 10min, melt index test condition: melting temperature is 230 ℃, load weight is 2.16K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com