Carbon dioxide-based polycarbonate containing abb structure and synthesis method thereof

A technology based on polycarbonate and carbon dioxide, applied in the field of carbon dioxide-based polycarbonate and its synthesis, can solve the problems such as the decline of mechanical properties of polymers, and achieve the effect of broadening the possibility and regulating the polymerization product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Embodiment 1 The synthetic method of the carbon dioxide-based polypropylene carbonate containing abb structure is as follows:

[0091] Adopt catalyst 1 structural formula as follows:

[0092]

[0093] Purified propylene oxide PO (3g, 51.7mmol) and catalyst 1 (25.6mg, 0.052mmol) were added to the autoclave under anhydrous and oxygen-free conditions, filled with carbon dioxide (2.0MPa), and reacted at 40°C for 6h. After the product is dissolved in dichloromethane, the impurity such as catalyst is washed away by precipitation with methanol solution of hydrochloric acid, and the following carbon dioxide-based polypropylene carbonate containing abb structure is obtained:

[0094]

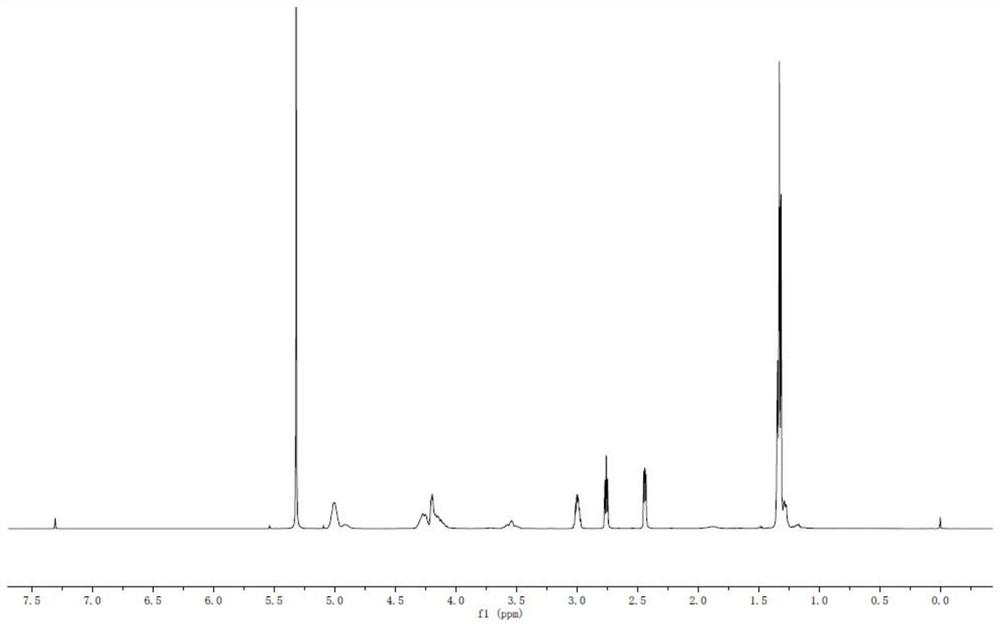

[0095] The results of hydrogen nuclear magnetic spectrum showed that the carbonate units accounted for 91.2%, the abb structural units accounted for 8.2%, and the ether units accounted for 0.5% (molar ratio) in the polypropylene carbonate.

Embodiment 2

[0097] The synthetic method of the carbon dioxide-based polypropylene carbonate containing abb structure is as follows:

[0098] Add purified propylene oxide PO (3g, 51.7mmol) and catalyst 1 (25.6mg, 0.052mmol) into the autoclave under anhydrous and oxygen-free conditions, fill with carbon dioxide (1.0MPa), and react at 90°C for 0.3h . After the product is dissolved in dichloromethane, the impurity such as catalyst is washed away by precipitation with methanol solution of hydrochloric acid, and the following carbon dioxide-based polypropylene carbonate containing abb structure is obtained:

[0099]

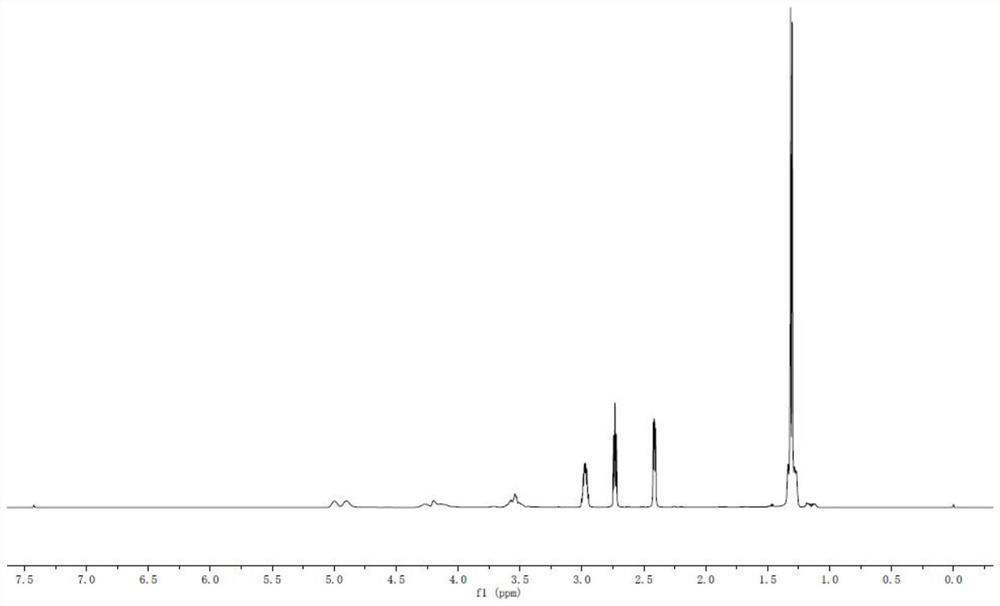

[0100] The results of hydrogen nuclear magnetic spectrum showed that the carbonate unit accounted for 57.8%, the abb structure unit accounted for 36.4%, and the ether unit accounted for 5.8% (molar ratio) in the polypropylene carbonate.

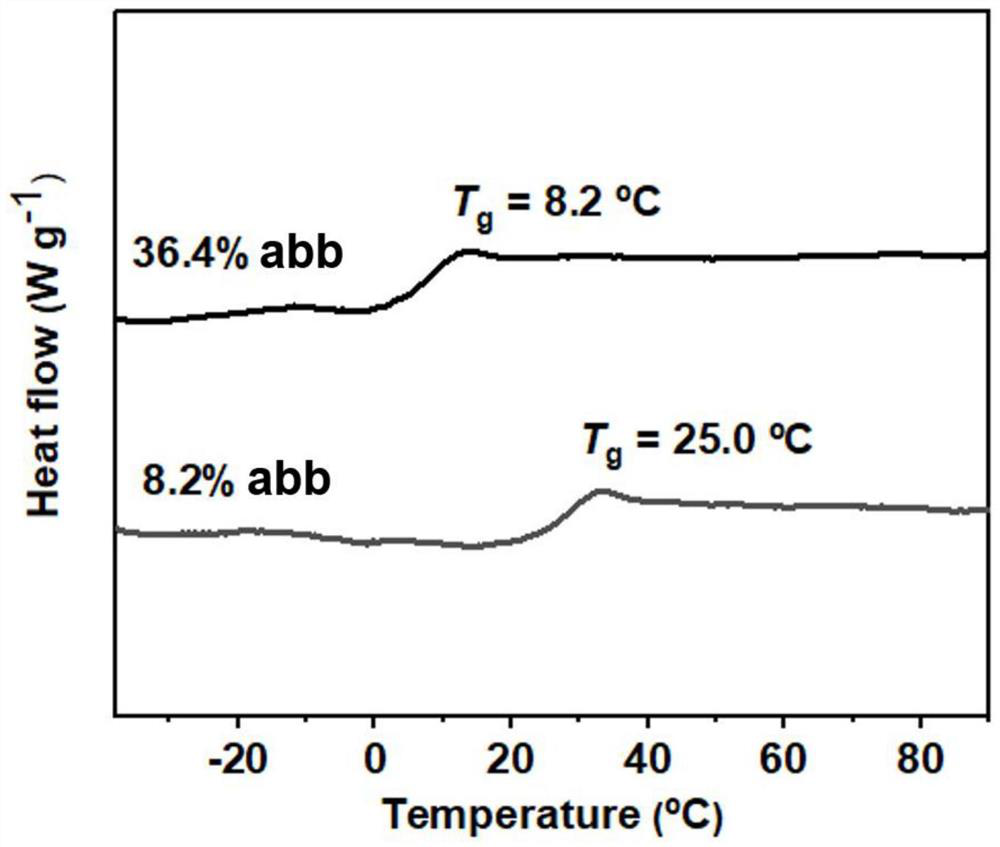

[0101] The DSC curve contrast chart of the polypropylene carbonate of different constituent unit ratios in embodiment 1,2 is as image 3 as s...

Embodiment 3

[0103] The synthetic method of the carbon dioxide-based polypropylene carbonate containing abb structure is as follows:

[0104] Adopt catalyst 2 structural formula as follows:

[0105]

[0106] Purified propylene oxide PO (3g, 51.7mmol) and catalyst 2 (38.8mg, 0.052mmol) were added to the autoclave under anhydrous and oxygen-free conditions, filled with carbon dioxide (2.0MPa), and reacted at 40°C for 6h. After the product is dissolved in dichloromethane, the impurity such as catalyst is washed away by precipitation with methanol solution of hydrochloric acid, and the following carbon dioxide-based polypropylene carbonate containing abb structure is obtained:

[0107]

[0108] The results of hydrogen nuclear magnetic spectrum showed that the carbonate units accounted for 69.7%, the abb structural units accounted for 21.4%, and the ether units accounted for 8.9% (molar ratio) in the polypropylene carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com