Microbial organic fertilizer and production method thereof

A technology of microbial organic fertilizer and microbial inoculum, which is applied in the treatment of biological organic parts, organic fertilizers, and microorganisms, can solve the problems of insufficient soil water holding capacity and insufficient drought resistance, so as to improve the utilization rate of water and fertilizer and reduce leaching losses. , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

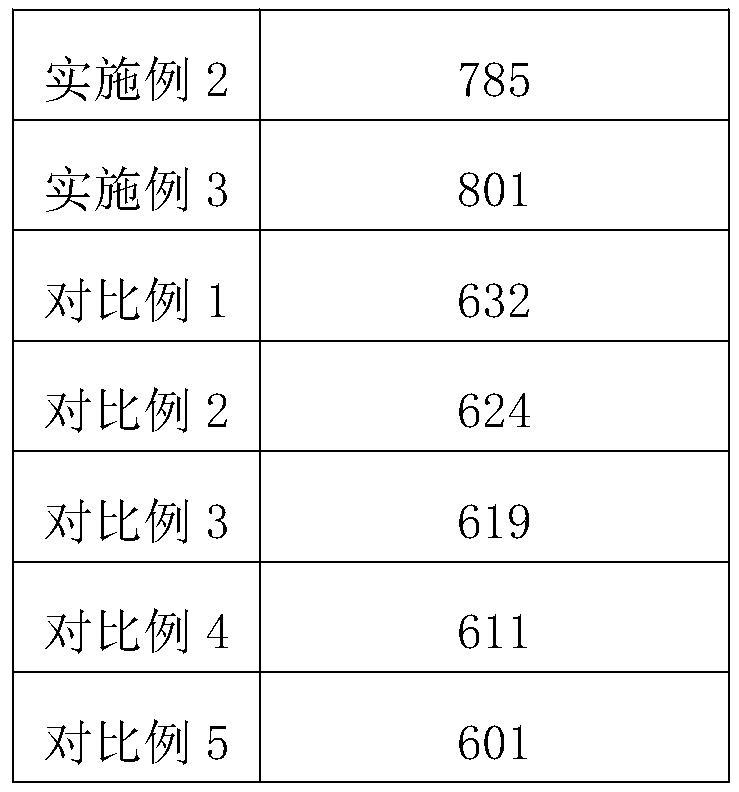

Examples

Embodiment 1

[0022] A microbial organic fertilizer, made from the following raw materials in parts by weight: 200 parts of decomposed farmyard manure, 5 parts of nitrogen, phosphorus and potassium compound fertilizer, 3 parts of water-retaining agent, 0.03 parts of microbial agent, and 30 parts of water; the water-retaining agent is by weight The ratio is a mixture of dextrin, acrylamide and borax in a ratio of 15:5:0.1; the microbial agent is a mixture of colloid bacillus, nitrifying bacteria and curved bacillus in a weight ratio of 10:3:0.1.

[0023] The preparation method of the above-mentioned water-retaining agent is as follows: add dextrin to water, mix evenly, heat up to 50°C, add acrylamide and borax, heat up to 80°C, stir for 20 minutes, dry to constant weight, and pulverize to obtain the water-retaining agent.

[0024] The production method of above-mentioned microorganism organic fertilizer, comprises the following steps:

[0025] (1) Mix decomposed farmyard manure and nitrogen,...

Embodiment 2

[0029] A microbial organic fertilizer, made of the following raw materials in parts by weight: 250 parts of decomposed farmyard manure, 8 parts of nitrogen, phosphorus and potassium compound fertilizer, 6 parts of water-retaining agent, 0.06 part of microbial agent, and 50 parts of water; the water-retaining agent is by weight The ratio is a mixture of dextrin, acrylamide and borax in a ratio of 22:8:0.6; the microbial agent is a mixture of colloid bacillus, nitrifying bacteria and campylobacter bacillus in a weight ratio of 15:6:0.8.

[0030] The preparation method of the above-mentioned water-retaining agent is as follows: add dextrin to water, mix evenly, heat up to 60°C, add acrylamide and borax, heat up to 90°C, stir for 30 minutes, dry to constant weight, and pulverize to obtain the water-retaining agent.

[0031] The production method of above-mentioned microorganism organic fertilizer, comprises the following steps:

[0032] (1) Mix decomposed farmyard manure and nitro...

Embodiment 3

[0036] A microbial organic fertilizer, made of the following raw materials in parts by weight: 230 parts of decomposed farmyard manure, 6 parts of nitrogen, phosphorus and potassium compound fertilizer, 5 parts of water-retaining agent, 0.05 part of microbial agent, and 40 parts of water; the water-retaining agent is by weight The ratio is a mixture of dextrin, acrylamide and borax in a ratio of 18:6:0.3; the microbial agent is a mixture of colloid bacillus, nitrifying bacteria and campylobacter bacillus in a weight ratio of 13:5:0.5.

[0037] The preparation method of the above water retaining agent is as follows: add dextrin to water, mix evenly, heat up to 55°C, add acrylamide and borax, heat up to 85°C, stir for 25 minutes, dry to constant weight, and pulverize to obtain the water retaining agent.

[0038] The production method of above-mentioned microorganism organic fertilizer, comprises the following steps:

[0039] (1) Mix decomposed farmyard manure and nitrogen, phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com