Rolling sagger and powder sintering method

A technology for saggar and powder materials, which is applied in the field of rolling saggar and powder sintering. It can solve the problems of difficult sintering, damage to saggar ceramic materials, and restrictions on the structure of rolling saggar. It achieves a simple and reliable fixed structure and reduces processing costs. Difficulty, the effect of reducing expansion stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

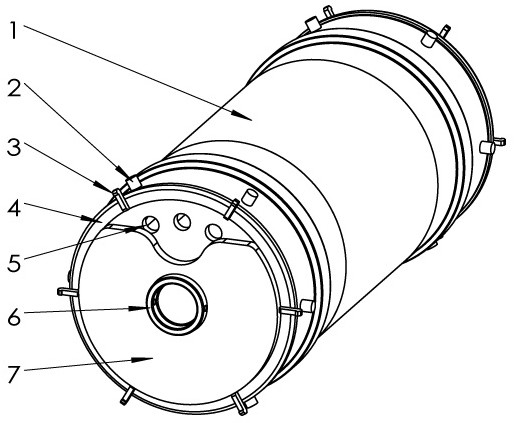

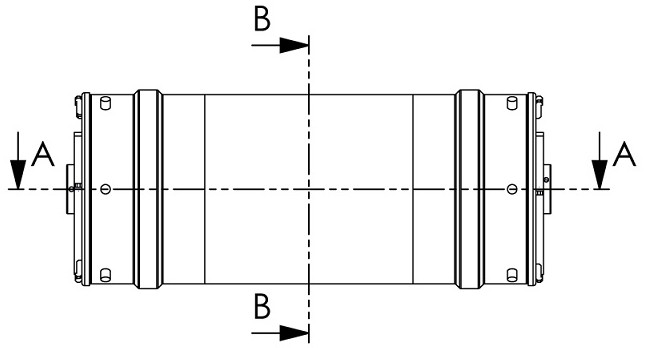

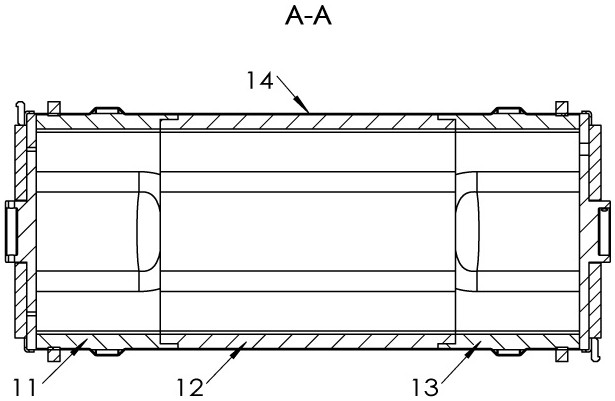

[0027] figure 1 and figure 2Shown is a specific structure of a rolling sagger of the present invention, including a sagger main body 1, which is a hollow cylinder surrounding the inner cavity and has a horizontal axis of rotation. A number of fixed columns 2 are fixed, and the two ends of the sagger main body 1 are detachably connected with a fixed cover 4. The fixed cover 4 is a circular plate, and its outer periphery is fixed with a number of fixed hooks 3. The number of fixed hooks 3 And the position is in one-to-one correspondence with the fixed column 2. The fixed cover plate 4 is provided with a through vent hole 5 , and the vent hole 5 communicates with the inner cavity of the sagger main body 1 . A side of the fixed cover 4 away from the sagger body 1 (hereinafter referred to as “outer side”) is fixed with a fixed shaft 6 , and the fixed shaft 6 is located at the geometric center of the fixed cover 4 . The outer side of the fixed cover plate 4 is provided with a mo...

Embodiment 2

[0031] A powder sintering method using the above-mentioned rolling sagger, comprising the following steps: putting powdery materials into the sagger main body 1, covering the opening end of the sagger main body 1 with the fixed cover plate 4, and making the fixed hook 3 and the fixed hook 3 The positions of the columns 2 correspond one by one, and each set of corresponding fixed hooks 3 and the fixed columns 2 are respectively connected and fixed together with detachable connectors. In this embodiment, the connectors are metal wires, and the powdery The rolling sagger of the material is put into the pusher tunnel kiln for high-temperature sintering, the rolling sagger rolls forward in the pusher tunnel kiln, and the movable cover 7 keeps the center of gravity lower than the fixed shaft 6 during the tumbling under the action of gravity and makes the At least one exhaust hole 5 on the upper part of the fixed cover plate 4 is in a connected state, and the rest of the exhaust holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com