Graded buffering high-shock-resistance bending-resistance pipe-in-pipe type guide pipe and fuel assembly

A fuel assembly and anti-bending technology, applied in the direction of pipes/pipe joints/pipes, assembly of fuel elements, pipe elements, etc., can solve the problems of not fully exerting mechanical properties, affecting the bearing capacity of guide pipes, and difficult to meet seismic requirements. , to achieve the effect of facilitating high fuel consumption operation, increasing the axial equivalent stiffness and transverse bending stiffness, alleviating thermal creep and irradiating the secondary side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

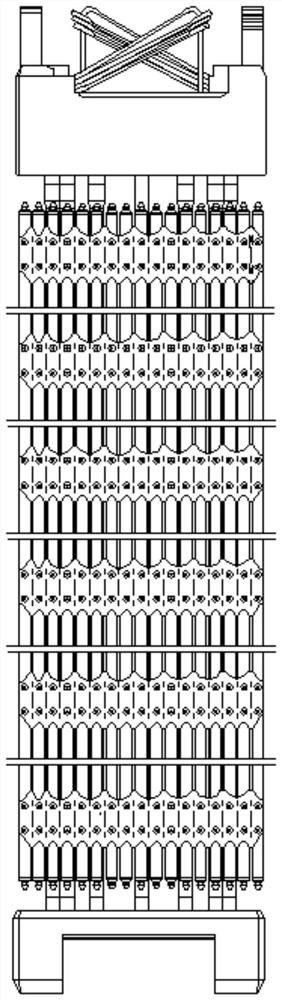

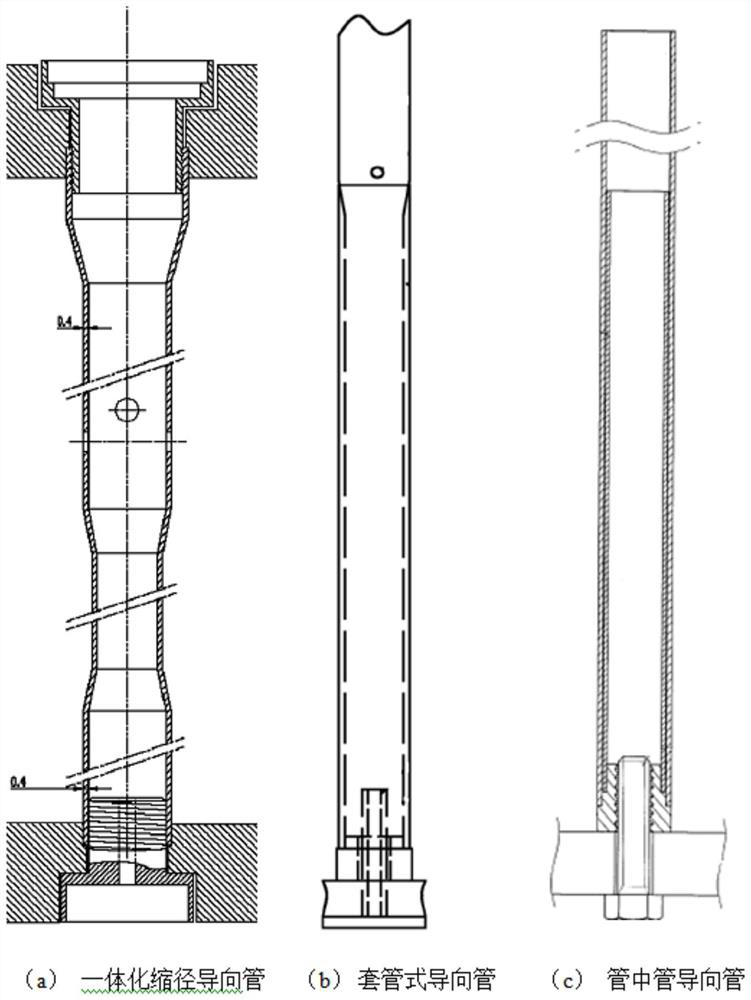

[0047] For existing guide tube structures (such as figure 2 As shown), there are gaps to form dead water areas, which are likely to cause crevice corrosion, and then affect the bearing capacity of the guide tube. The tube is a tube-in-tube structure with a simple manufacturing process (reduced inner diameter, increased wall thickness), which improves the equivalent stiffness of the guide tube, improves the shock resistance and bending resistance under high fuel consumption. At the same time, multi-level hydraulic buffering is realized through the opening of the inner tube, which reduces the impact load of falling rods, thereby reducing the maximum stress of the guide tube during operation, improving the bending resistance of the fuel assembly, and avoiding dead water areas to alleviate crevice corrosion, thereby improving the bearing capacity of the guide tube .

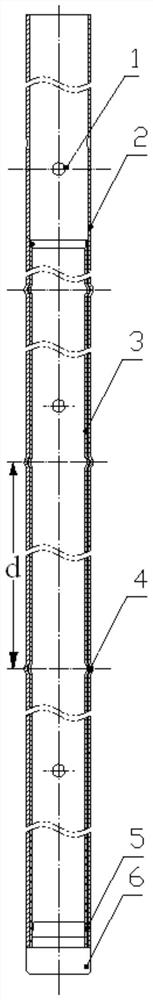

[0048] Specific as Figure 3-5 As shown, the guide tube 1 of this embodiment is composed of an outer tube 2, an ...

Embodiment 2

[0052] This embodiment further optimizes the above-mentioned embodiment 1, such as image 3 As shown, the inner tube 3 and the outer tube 2 are connected by expansion or welding, that is, as image 3 The outer tube shown is connected to the inner tube through the connection part 4, and the connection part 4 is a convex part formed by expansion or welding.

[0053] In this embodiment, the inner tube 3 is axially connected to the outer tube 2 through a plurality of connecting parts 4 . The distance between two adjacent connecting parts, that is, the connection distance between the inner pipe 3 and the outer pipe 2 is d, and the size of d should fully consider the span of the guide pipe in the fuel assembly. Evenly arranged on the span between; and the maximum value of d, Dmax, should meet the requirement that the inner tube and the outer tube do not touch when bearing the maximum axial load, realizing the effect of "bunching into a column" between the inner tube and the outer t...

Embodiment 3

[0055] This embodiment further optimizes the above-mentioned embodiment 1. In this embodiment, the upper end of the inner tube 3 is made into a slotted and opened structure 33, which can be automatically attached after being inserted into the outer tube 2, without welding or expansion joints 4, The manufacturing process is greatly simplified, while relative vibration and potential abrasion can be avoided, and structural reliability can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com