Refractory Al-Cr-Ti-V-Nb light high-entropy alloy and preparation method thereof

An al-cr-ti-v-nb, high-entropy alloy technology, applied in the field of alloys, can solve the problems of high density of refractory high-entropy alloys, which cannot be further satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

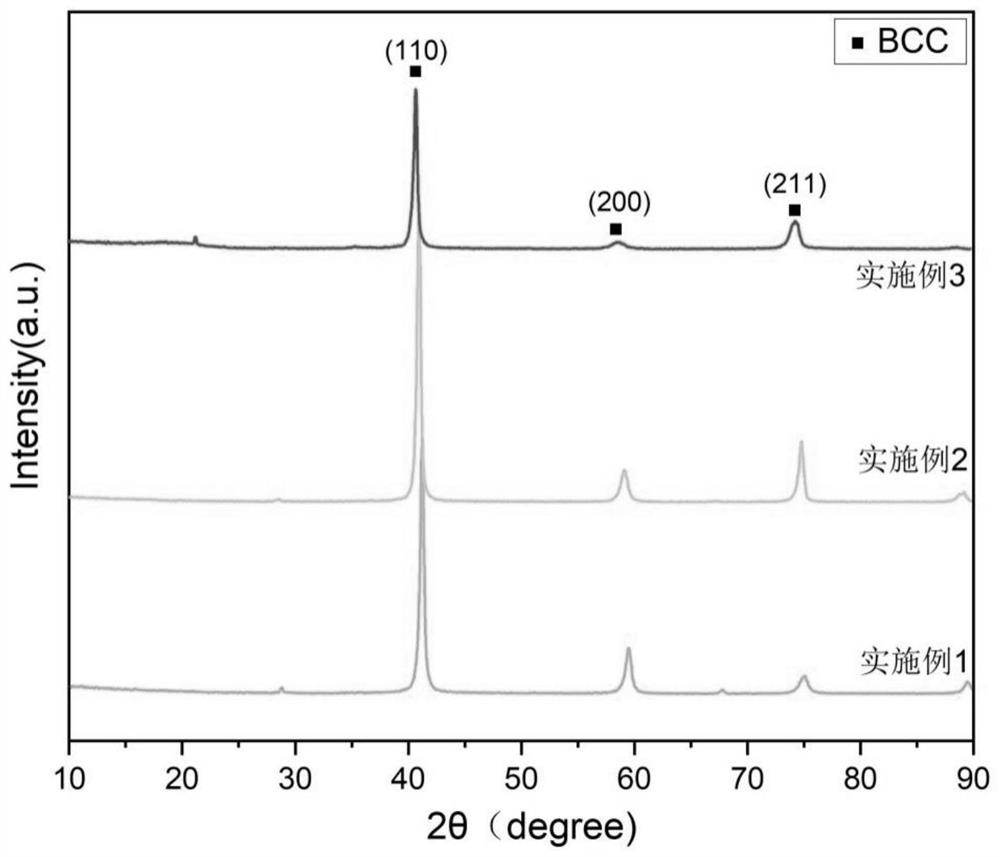

Embodiment 1

[0030] In the high-hardness Al-Cr-Ti-V-Nb lightweight high-entropy alloy in this example, the atomic percentages of each element are as follows: Al 24%, Cr 24%, Ti 24%, V 23%, and Nb 5%, expressed as Al 24 Cr 24 Ti 24 V 23 Nb 5 Lightweight high-entropy alloys.

[0031] Al above 24 Cr 24 Ti 24 V 23 Nb 5 The preparation method of lightweight high-entropy alloy is as follows:

[0032] (1) Prepare and weigh the metal raw materials Al, Cr, Ti, V, Nb and metal titanium blocks according to the proportioning ratio, and remove impurities and oxides on the raw materials and metal titanium blocks with sandpaper to remove the surface, and the purity of each metal raw material is uniform. If it is higher than 99.9wt%, use acetone as the cleaning solvent after polishing, perform vibration cleaning for 5 minutes in an ultrasonic cleaning machine with a power of 180W and a frequency of 40KHz, and then dry.

[0033] (2) In a non-consumable vacuum arc melting furnace, the metal titani...

Embodiment 2

[0036] In the high-hardness Al-Cr-Ti-V-Nb lightweight high-entropy alloy in this example, the atomic percentages of each element are as follows: Al 23%, Cr 23%, Ti 23%, V 22%, and Nb 9%, expressed as Al 23 Cr 23 Ti 23 V 22 Nb 9 Lightweight high-entropy alloys.

[0037] Al above 23 Cr 23 Ti 23 V 22 Nb 9 The preparation method of lightweight high-entropy alloy is as follows:

[0038] (1) prepare described metal raw material Al, Cr, Ti, V, Nb and metal titanium block according to proportioning, to raw material and metal titanium block use sandpaper to remove surface impurity and oxide, the purity of each metal raw material is all higher than 99.9 wt%, after polishing, use acetone as the cleaning solvent, perform vibration cleaning for 5 minutes in an ultrasonic cleaning machine with a power of 180W and a frequency of 40KHz, and dry.

[0039] (2) In a non-consumable vacuum arc melting furnace, the metal titanium block is first melted under the protection of argon, and th...

Embodiment 3

[0042] In the high-hardness Al-Cr-Ti-V-Nb lightweight high-entropy alloy in this example, the atomic percentages of each element are as follows: Al22%, Cr 22%, Ti 22%, V 22%, and Nb 12%, expressed as Al 22 Cr 22 Ti 22 V 22 Nb 12 Lightweight high-entropy alloys.

[0043] Al above 22 Cr 22 Ti 22 V 22 Nb 12 The preparation method of lightweight high-entropy alloy is as follows:

[0044] (1) Prepare the metal raw materials Al, Cr, Ti, V, Nb and metal titanium blocks according to the proportioning, and remove impurities and oxides on the raw materials and metal titanium blocks with sandpaper, and the purity of each metal raw material is higher than 99.9 wt%, after polishing, use acetone as the cleaning solvent, perform vibration cleaning for 5 minutes in an ultrasonic cleaning machine with a power of 180W and a frequency of 40KHz, and dry.

[0045] (2) In a non-consumable vacuum arc melting furnace, the metal titanium block is first melted under the protection of argon, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com