Beta-amylase production system and production process thereof

A production system and technology of β-amylase, applied in the field of β-amylase production system and its production process, can solve the problems of low cleaning efficiency, wrinkled filter cloth, and poor filter press effect, so as to enhance the deslagging effect and reduce the Labor intensity, the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

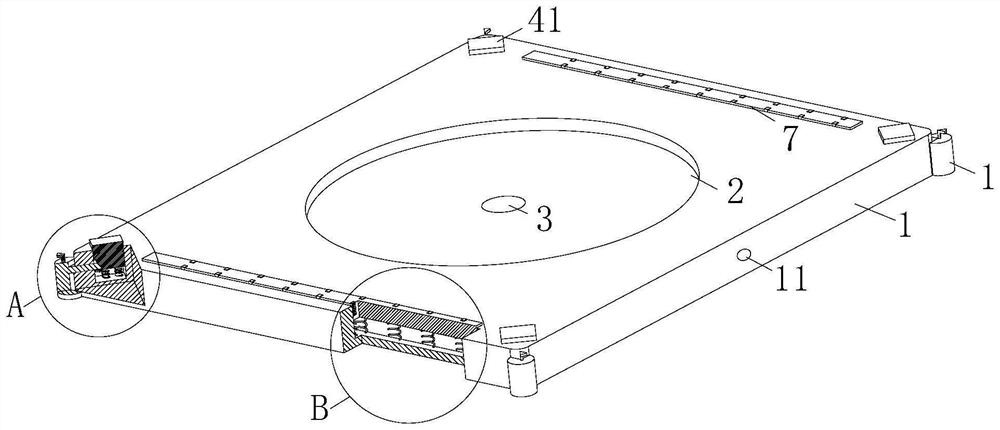

[0047] As an embodiment of the present invention, the cross-sectional shape of the groove 2 can be one of rectangle, circle, and regular polygon, and the cross-sectional shape of the through groove 5 can be one of rectangle, circle, and regular polygon. kind;

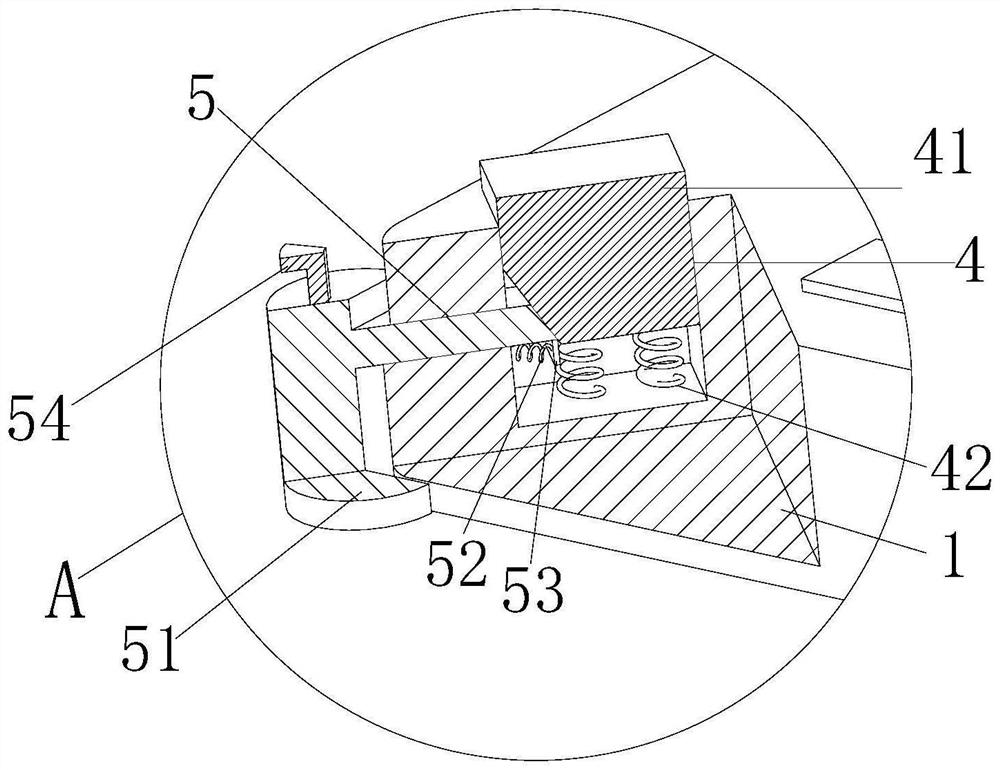

[0048] As an embodiment of the present invention, shaking parts with the same structure are arranged on both sides of the groove 2, and the shaking parts include No. 2 groove 6, and the No. 2 groove 6 is vertically arranged with the filter plate 1, so A push bar 7 is slidingly arranged in the No. 2 groove 6, and a number of No. 3 springs 61 are clipped between the bottom of the push bar 7 and the bottom of the No. 2 slot 6. The top of the push bar 7 is vertically aligned with the push bar 7. There are several No. 3 grooves 71 straight downward, and a shaking block 73 is slidably connected in the No. 3 groove 71. The bottom of the shaking block 73 is connected to the bottom of the No. 3 groove 71 through a No. 4 spring 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com