Furyl phosphate flame retardant and preparation method thereof

A technology of furan-based phosphate ester and flame retardant is applied in the field of phosphorus-containing bio-based flame retardant materials and preparation, and achieves the effects of rich aromatic ring structure, high molecular weight and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

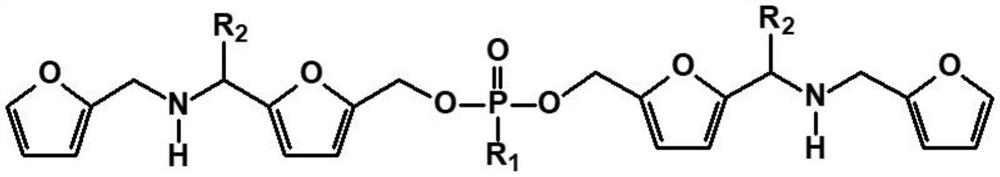

[0025] A kind of furyl phosphate flame retardant, the structure of this flame retardant is shown in the following formula:

[0026]

[0027] The preparation method of above-mentioned furyl phosphate flame retardant is, comprises the following steps

[0028] (1) 5-Hydroxymethylfurfural and triethylamine are dissolved in dichloromethane, then dropwise add dichlorinated phenyl phosphate, the mole of dichlorinated phenyl phosphate, 5-hydroxymethylfurfural and triethylamine The ratio is 1.0:2.0:2.0, react at 0°C for 3 hours, filter the reactant, wash the filtrate with water, and use a rotary evaporator to remove the solvent in the organic phase to obtain a phosphorus-containing furanyl intermediate;

[0029] (2) Add the phosphorus-containing furanyl intermediate, furfurylamine and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into the reactor according to the stoichiometric ratio, and the phosphorus-containing furanyl intermediate The molar ratio of the body, furfurylamine...

Embodiment 2

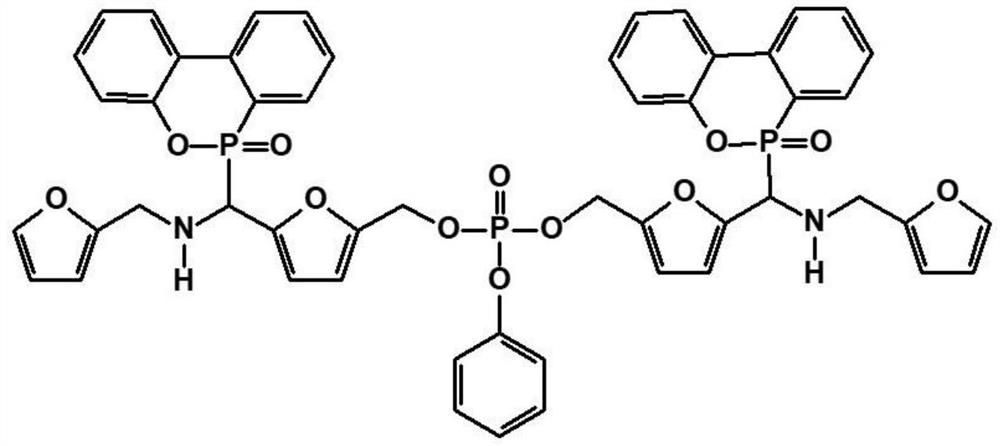

[0035] A kind of furyl phosphate flame retardant, the structure of this flame retardant is shown in the following formula:

[0036]

[0037] The preparation method of above-mentioned furyl phosphate flame retardant is, comprises the following steps

[0038] (1) 5-hydroxymethylfurfural and pyridine are dissolved in chloroform, then dropwise add phenylphosphonic dichloride, the mol ratio of phenylphosphonic dichloride, 5-hydroxymethylfurfural and pyridine is 1.0: 2.1: 2.1, react at 60°C for 8 hours, filter the reactant, wash the filtrate with water, and use a rotary evaporator to remove the solvent in the organic phase to obtain a phosphorus-containing furanyl intermediate;

[0039] (2) Add the phosphorus-containing furyl intermediate, furfurylamine and diphenylphosphoryl oxide into the reactor according to the stoichiometric ratio, and the molar ratio of the phosphorus-containing furyl intermediate, furfurylamine and diphenylphosphoryl oxide is 1.0:2.1 : 2.1, reacted at 50°...

Embodiment 3

[0045] A kind of furyl phosphate flame retardant, the structure of this flame retardant is shown in the following formula:

[0046]

[0047] The preparation method of above-mentioned furyl phosphate flame retardant is, comprises the following steps

[0048](1) 5-hydroxymethylfurfural and triethylamine are dissolved in tetrahydrofuran, then dropwise add methyl dichlorophosphate, the mol ratio of methyldichlorophosphate, 5-hydroxymethylfurfural and triethylamine is 1.0: 2.2: 2.2, react at 30°C for 12 hours, filter the reactant, wash the filtrate with water, and remove the solvent in the organic phase by a rotary evaporator to obtain a phosphorus-containing furanyl intermediate;

[0049] (2) Add the phosphorus-containing furanyl intermediate, furfurylamine and dimethyl phosphite into the reactor according to the stoichiometric ratio, and the molar ratio of the phosphorus-containing furanyl intermediate, furfurylamine and dimethylphosphite is 1.0:2.2 : 2.2, reacted at 80° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com