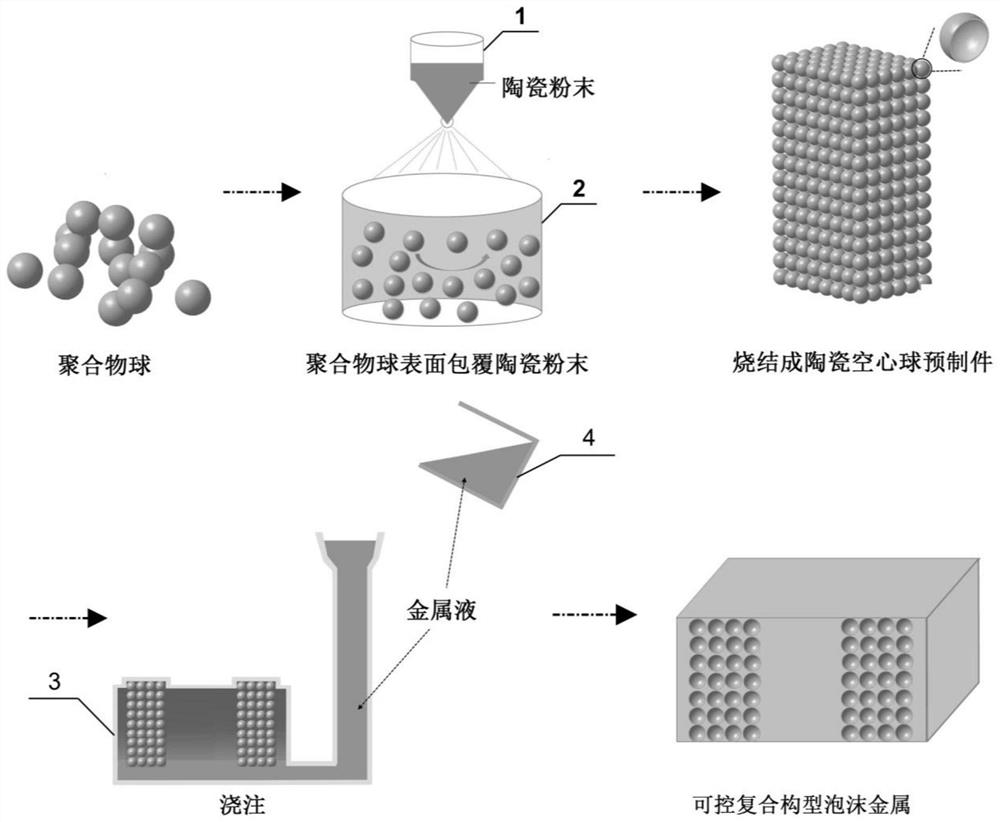

Casting forming method of composite-configuration foam metal material

A metal foam and casting forming technology, which is applied in the field of metal foam, can solve problems such as the difficulty in realizing the controllable adjustment of complex configurations, the complicated process of metal foam in composite configurations, and the long process. Engineering applicability, controllable and adjustable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

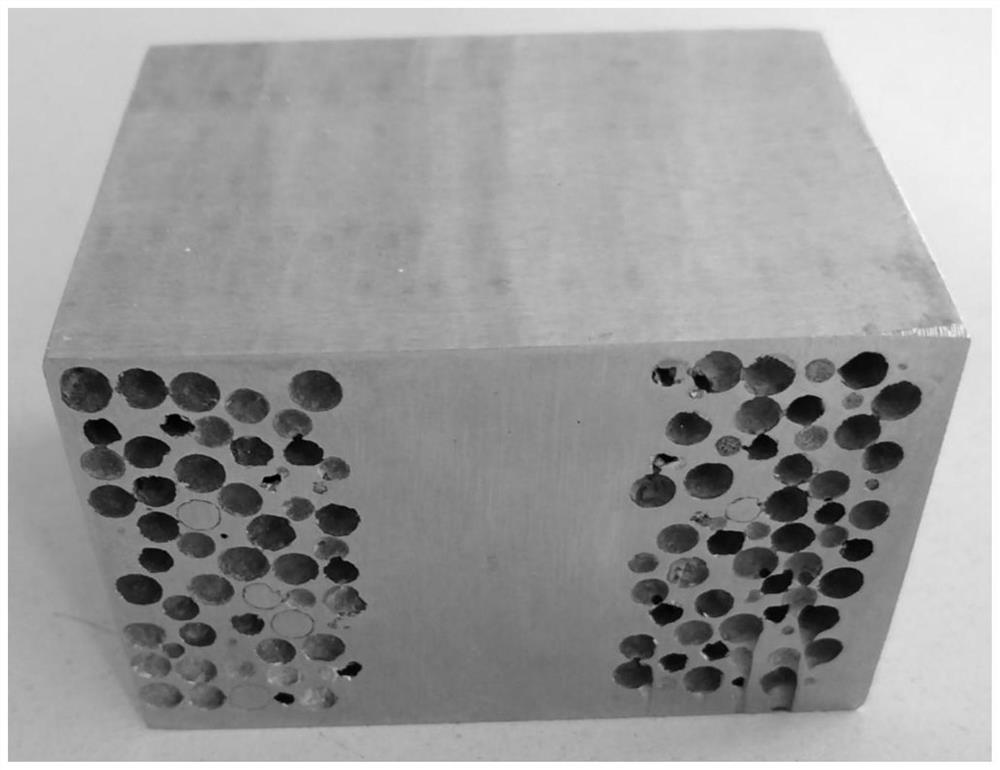

Examples

Embodiment 1

[0030] 1) Place a polymer ball (StMMA copolymer ball) with a diameter of 3mm in a roll coater equipped with an ethyl silicate binder, and the roll coater makes a circular motion at a speed of 25 rpm, and the polymer The ball is evenly wrapped by the binder during the rolling process.

[0031] 2) Use a ceramic powder sprayer to evenly spray a layer of alumina ceramic powder with a thickness of 70-80 μm on the surface of the polymer ball wrapped with the binder.

[0032] 3) Put the polymer balls coated with the binder and the alumina ceramic powder on the surface into a drying oven, and dry at 100° C. for 3 hours to obtain dry polymer balls coated with the outer layer of the ceramic powder.

[0033] 4) Repeat steps 1), 2), and 3) until the thickness of the ceramic powder on the outer layer of the polymer ball reaches about 230 μm.

[0034] 5) Design the mold according to the structural characteristics of the composite configuration, place the pellets in the mold, and transfer t...

Embodiment 2

[0037] Except that the diameter of the polymer ball selected in step 1) is 4 mm, and the thickness of the coating layer is 180 μm, all other steps and process parameters are the same as in Example 1.

Embodiment 3

[0039] Except that the diameter of the polymer ball selected in step 1) is 5 mm, and the thickness of the coating layer is 150 μm, the sintering temperature in step 5) is: heating to 600 ° C at a heating rate of 5 ° C / min to completely burn the polymer ball, Heat to 900°C at a heating rate of 10°C / min, then heat to 1350°C at a rate of 50°C / min, and hold for 4 hours. All other steps and processing parameters are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com