Material with antibacterial and osteogenesis promoting performance and preparation method thereof

A technology that promotes bone and performance. It is used in medical science, prosthesis, tissue regeneration, etc. to achieve high safety, promote bone repair, and improve osteogenic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

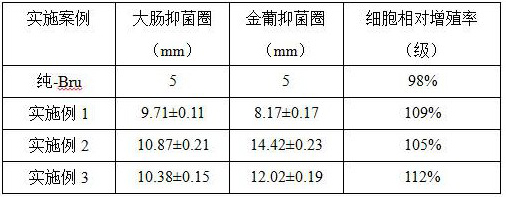

Examples

preparation example Construction

[0033] A method for preparing a material with antibacterial and bone-promoting properties, comprising the following steps:

[0034] S1, load gallium β-calcium phosphate (gallium accounts for 2-5 mol% of the total metal ions in molar weight) and Ca(H 2 PO 4 ) 2 ·H 2 O powder is ground separately, and is standby after sieving;

[0035] S2. Weigh the loaded gallium β-calcium phosphate and Ca(H 2 PO 4 ) 2·H 2 The O powder is mixed and ground to obtain a mixed powder for subsequent use;

[0036] S3, adding calcium alginate microspheres loaded with acidic fiber growth factor to S2, grinding and mixing evenly;

[0037] S4, preparation concentration is the chitosan solution of 0.8~1.2wt% as bone cement liquid phase, stand-by;

[0038] S5. Add the solution prepared by S4 to the mixed powder prepared in S3 at a ratio of 2.2 to 3 g / mL, and stir to obtain a uniform slurry, and put it into a mold;

[0039] S6. After the material is solidified and demolded, the product is obtain...

Embodiment example 1

[0056] S1. Preparation of gallium-loaded β-TCP

[0057] S11. Prepare 3 L (Ga / (Ga +Ca)= 2 mol%) of Ca(NO 3 ) 2 and Ga(NO 3 ) 3 Mixed solution, Ca in the solution 2+ and Ga 3+ The concentration is 0.1 mol / L.

[0058] S12, in the solution of S11, dropwise add 2 L concentration be the (NH 4 ) 2 HPO 4 solution. During the 4 h reaction, stirring was continued, and NH 3 ·H 2 O, keep the pH around 7-8.

[0059] S13. Precipitate the mixed suspension of S12 at 40°C for 24 h, suction filter the precipitate obtained from the reaction, put the filter cake into a glass dish, and dry it in a drying oven at 110°C for 24 h.

[0060] S14. Calcining the dried semi-finished material of S13 at 1100° C. for 2 h, pulverizing the sintered powder, and sieving with 200 mesh.

[0061] S2. Preparation of calcium alginate microspheres loaded with acidic fibroblast growth factor

[0062] S21. Prepare 1wt% sodium alginate solution A1 and store it at 4°C for later use;

[0063] S22. Weighing ...

Embodiment example 2

[0074] S1. Preparation of gallium-loaded β-TCP

[0075] S11. Prepare 3 L (Ga / (Ga +Ca)= 3mol%) of Ca(NO 3 ) 2 and Ga(NO 3 ) 3 Mixed solution, Ca in the solution 2+ and Ga 3+ The concentration is 0.1 mol / L.

[0076] S12, in the solution of S11, dropwise add 2 L concentration be the (NH 4 ) 2 HPO 4 solution. During the 4 h reaction, stirring was continued, and NH 3 ·H 2 O, keep the pH around 7-8.

[0077] S13. Precipitate the mixed suspension of S12 at 40°C for 24 h, suction filter the precipitate obtained from the reaction, put the filter cake into a glass dish, and dry it in a drying oven at 110°C for 24 h.

[0078] S14. Calcining the dried semi-finished material of S13 at 1100° C. for 2 h, pulverizing the sintered powder, and sieving with 200 mesh.

[0079] S2. Preparation of calcium alginate microspheres loaded with acidic fibroblast growth factor

[0080] S21. Prepare 1wt% sodium alginate solution A1 and store it at 4°C for later use;

[0081] S22. Weighing 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com