Injectable temperature-sensitive hydrogel as well as preparation method and application thereof

A technology of temperature-sensitive hydrogel and preparation steps, which is applied in the field of biomedicine, can solve the problems of insufficient antibacterial concentration, limited curative effect of mechanical therapy, and increased bacterial resistance, so as to achieve the promotion of injectable performance, excellent antibacterial ability, and enhanced antibacterial The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

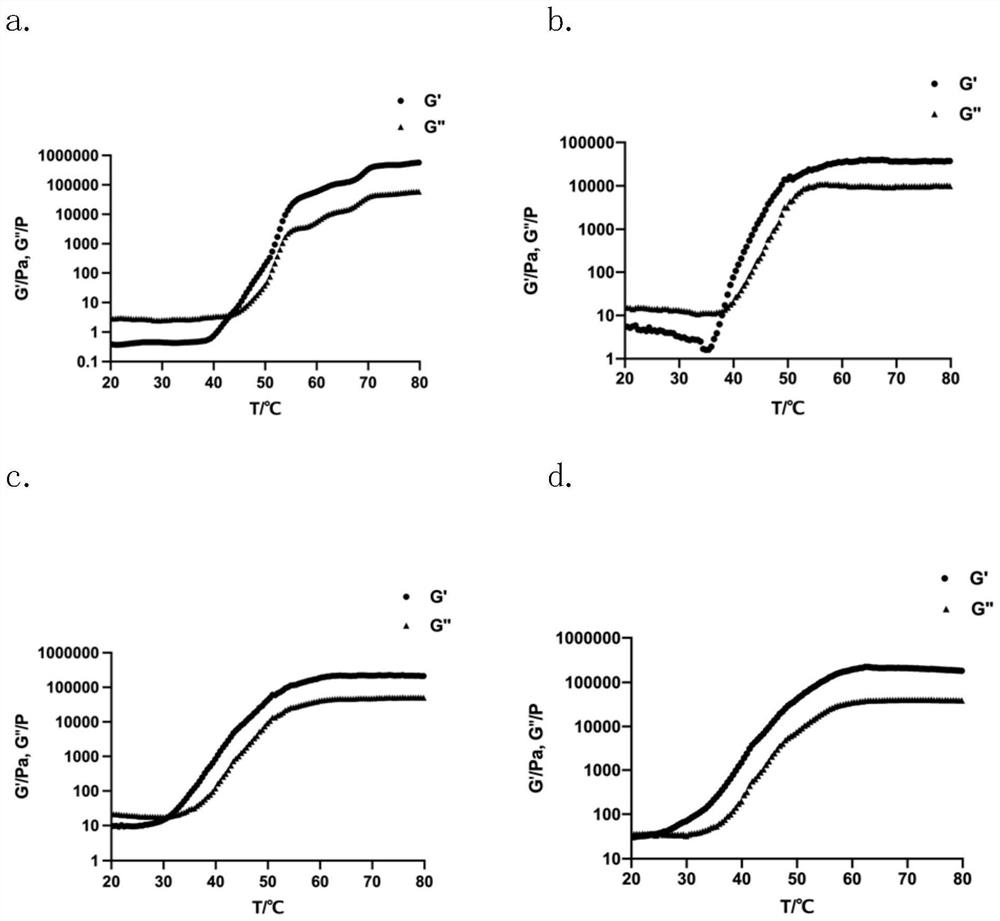

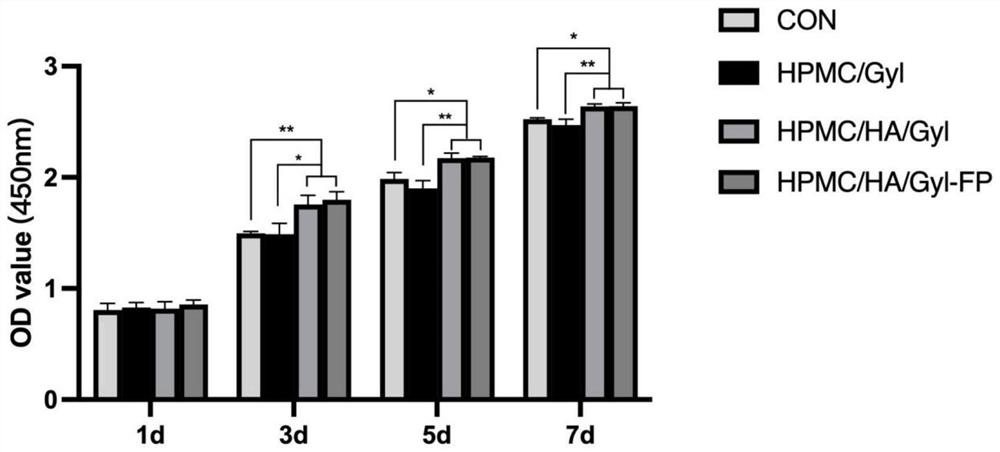

Image

Examples

Embodiment 1

[0019] (1) Weigh 1.4g of hydroxypropyl methylcellulose, 2g of hyaluronic acid, 0.1g of phentermine polypeptide and 2mL of glycerin;

[0020] (2) Add hydroxypropyl methylcellulose into 14mL of ultrapure water not lower than 80°C and stir well, stir well and then equilibrate overnight at 4°C to obtain a hydroxypropylmethylcellulose solution;

[0021] (3) Prepare hyaluronic acid with 20mL ultrapure water to make a solution with a mass concentration of 10%, and set it aside;

[0022] (4) Prepare the phenmu peptide with 1mL ultrapure water to make a solution with a mass concentration of 10%, and set it aside;

[0023] (5) Add 4 mL of the hyaluronic acid solution obtained in step (3) dropwise to the hydroxypropyl methylcellulose solution at room temperature, and stir evenly to obtain a mixed solution of hydroxypropyl methylcellulose / hyaluronic acid;

[0024] (6) Add 100 μL of the phentermine polypeptide solution obtained in step (4) dropwise to the hydroxypropyl methylcellulose / hya...

Embodiment 2

[0027] (1) Weigh 1.4 g of hydroxypropyl methylcellulose, 2 g of hyaluronic acid, 0.1 g of phentermine polypeptide and 3 mL of glycerin;

[0028] (2) Add hydroxypropyl methylcellulose to 13mL of ultrapure water not lower than 80°C and stir thoroughly, stir evenly and equilibrate overnight at 4°C to obtain a hydroxypropyl methylcellulose solution;

[0029] (3) Prepare hyaluronic acid with 20mL ultrapure water to make a solution with a mass concentration of 10%, and set it aside;

[0030] (4) Prepare the phenmu peptide with 1mL ultrapure water to make a solution with a mass concentration of 10%, and set it aside;

[0031] (5) Add 4 mL of the hyaluronic acid solution obtained in step (3) dropwise to the hydroxypropyl methylcellulose solution at room temperature, and stir evenly to obtain a mixed solution of hydroxypropyl methylcellulose / hyaluronic acid;

[0032] (6) Add 100 μL of the phentermine polypeptide solution obtained in step (4) dropwise to the hydroxypropyl methylcellulo...

Embodiment 3

[0035] (1) Weigh 1.4 g of hydroxypropyl methylcellulose, 2 g of hyaluronic acid, 0.1 g of phentermine polypeptide and 4 mL of glycerin;

[0036] (2) Add hydroxypropyl methylcellulose to 12mL of ultrapure water not lower than 80°C and stir well, stir evenly and equilibrate overnight at 4°C to obtain a hydroxypropyl methylcellulose solution;

[0037] (3) Prepare hyaluronic acid with 20mL ultrapure water to make a solution with a mass concentration of 10%, and set it aside;

[0038] (4) Prepare the phenmu peptide with 1mL ultrapure water to make a solution with a mass concentration of 10%, and set it aside;

[0039] (5) Add 4 mL of the hyaluronic acid solution obtained in step (3) dropwise to the hydroxypropyl methylcellulose solution at room temperature, and stir evenly to obtain a mixed solution of hydroxypropyl methylcellulose / hyaluronic acid;

[0040] (6) Add 100 μL of the phentermine polypeptide solution obtained in step (4) dropwise to the hydroxypropyl methylcellulose / hya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com