Ultralight lead-free medical flexible X-ray shielding clothes and preparation method thereof

A technology of X-ray and shielding clothing, which is applied in the field of ultra-light lead-free medical flexible X-ray shielding clothing and its preparation, can solve the problems of unfavorable long-term use, pollution, panic, etc., and achieve the service life of environmental protection and strong X-ray absorption capacity , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

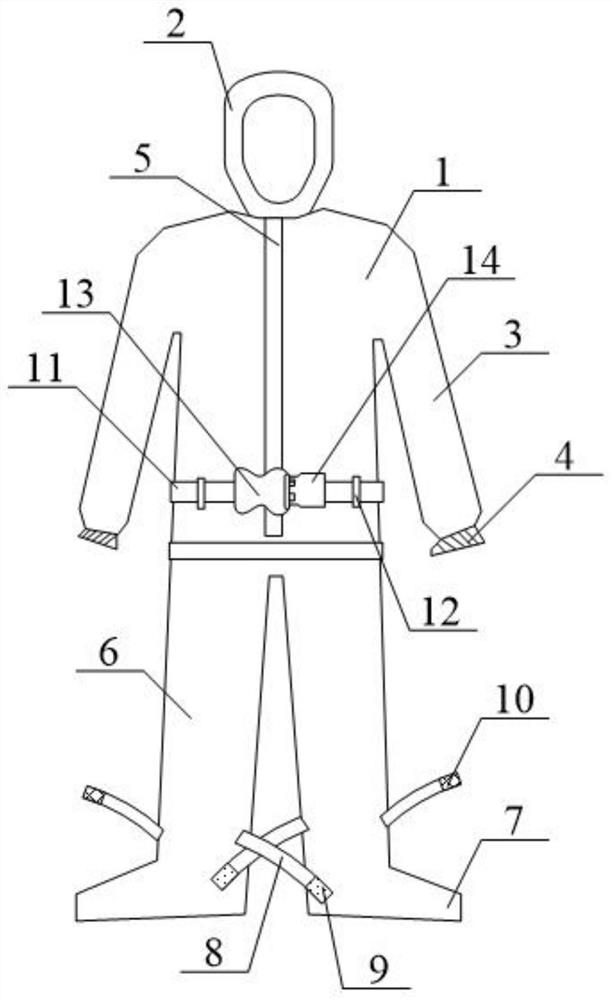

[0034] An ultra-light lead-free medical flexible X-ray shielding suit, comprising an upper garment body 1, a protective cap body 2, sleeves 3, cuff straps 4, fitting strips 5, a lower garment body 6, a foot cover body 7, and ankle restraints Belt 8, child velcro 9, female velcro 10, waist restraint belt 11, restraint ring 12, deck 13 and buckle plate 14, described protective cap body 2 is integrally sewn on the top of upper garment body 1; The sleeves 3 are sewn on the top of the left and right sides of the upper garment body 1 respectively; and the joint of the lower part; the foot cover body 7 is integrally sewn on the lower part of the lower clothing body 6;

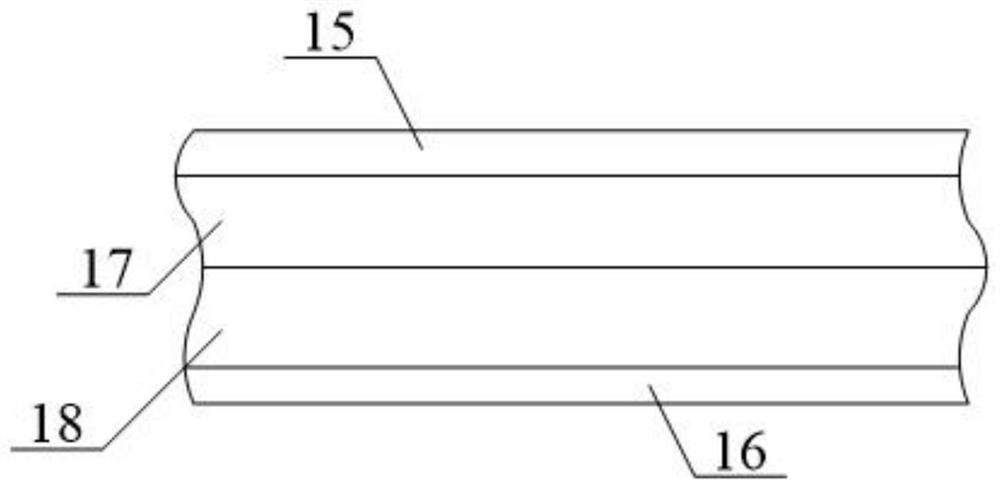

[0035] The body of the ultra-light lead-free medical flexible X-ray shielding suit is composed of an outer rubber layer 15, an inner rubber layer 16, a protective buffer layer 17 and an adhesive layer 18, and the described protective buffer layer 17 is composite metal powder layer, the composite metal powder layer co...

Embodiment 2

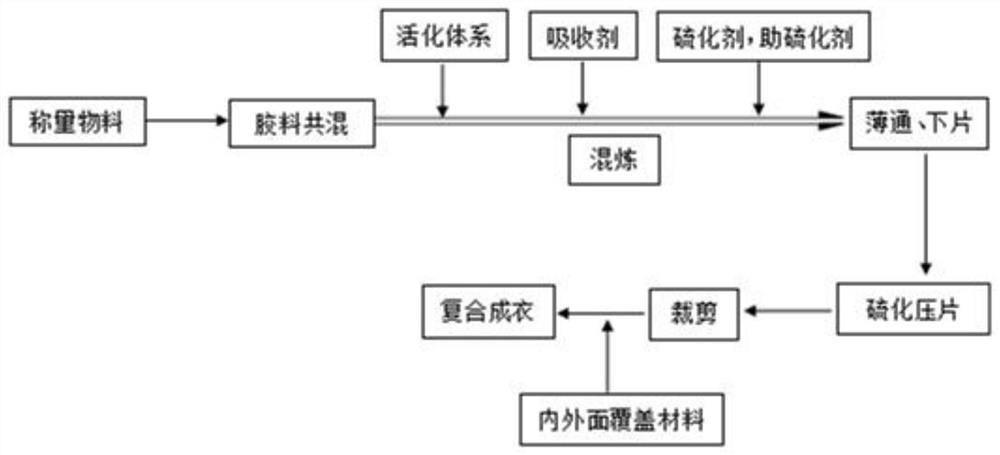

[0051] A method for preparing ultra-light lead-free medical flexible X-ray shielding clothing specifically includes the following steps:

[0052] S101: Weighing of prepared materials for use: 120 parts of qualified rubber, 1200 parts of composite metal powder, 5 parts of plasticizer, 3 parts of stearic acid, and 10 parts of vulcanizing agent are selected for use;

[0053] S102: Stirring and activation of materials: heat and stabilize the mixture of the rubber and composite metal powder materials in step 1 within a temperature range of 280° C. for 1.2 hours, and perform stirring and mixing treatment to obtain a pretreated mixture;

[0054] S103: Addition of binder: 5 parts of plasticizer, 3 parts of stearic acid and 10 parts of vulcanizing agent are added during the stirring process;

[0055] S104: Thin-pass unloading of the preparatory material: discharge and cool down until the temperature is 50°C, and then unload;

[0056] S105: vulcanized tablet molding; perform vulcanizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com