Application of monoamine oxidase in preparation of tropinone

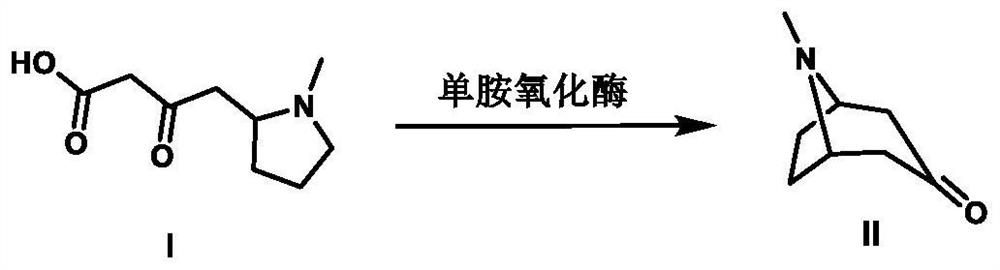

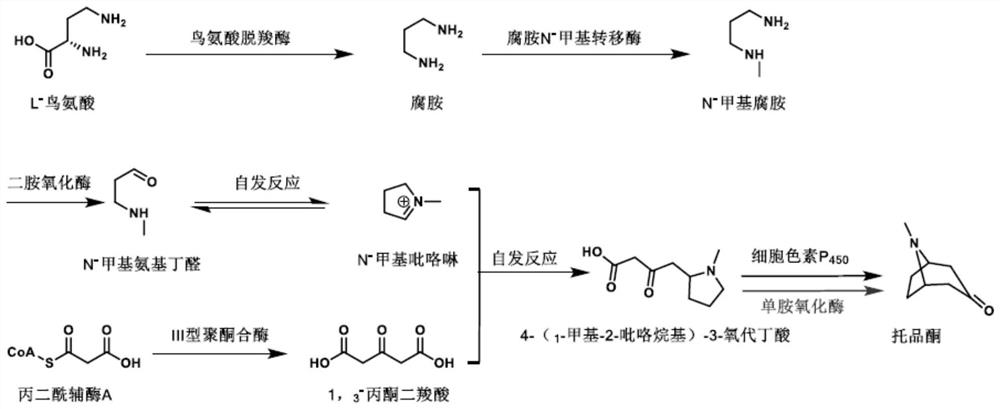

A technology of monoamine oxidase and tropinone, applied in the field of enzyme catalysis and synthetic biology, can solve the problems of insufficient stability and low expression, and achieve the effects of improving the cyclization reaction, solving the rate-limiting step, and having high application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Construction of Monoamine Oxidase Heterologous Expression Strain

[0028] Take Escherichia coli competent cells E.coli BL21 out of the -80°C refrigerator and place them on ice, pipette 1 microliter of the constructed monoamine oxidase expression plasmid pET28a-MAO into the competent cells, mix gently, Ice-bathed for 30 minutes, then placed in a 42°C water bath for heat shock for 90 seconds, immediately placed on ice for 2 minutes, and added 1 mL of LB to the transformation system. After cultivating on a shaker at 37°C for 40-60 minutes, take out the low-speed centrifugation for 3 minutes, discard most of the supernatant, gently blow the resuspended bacteria with a pipette gun, and spread it on the LA plate containing 50 μg / mL kanamycin antibiotic Above, cultivate in a 37°C incubator for 8-12 hours, and the obtained transformant with kanamycin resistance is the monoamine oxidase heterologous expression strain.

Embodiment 2

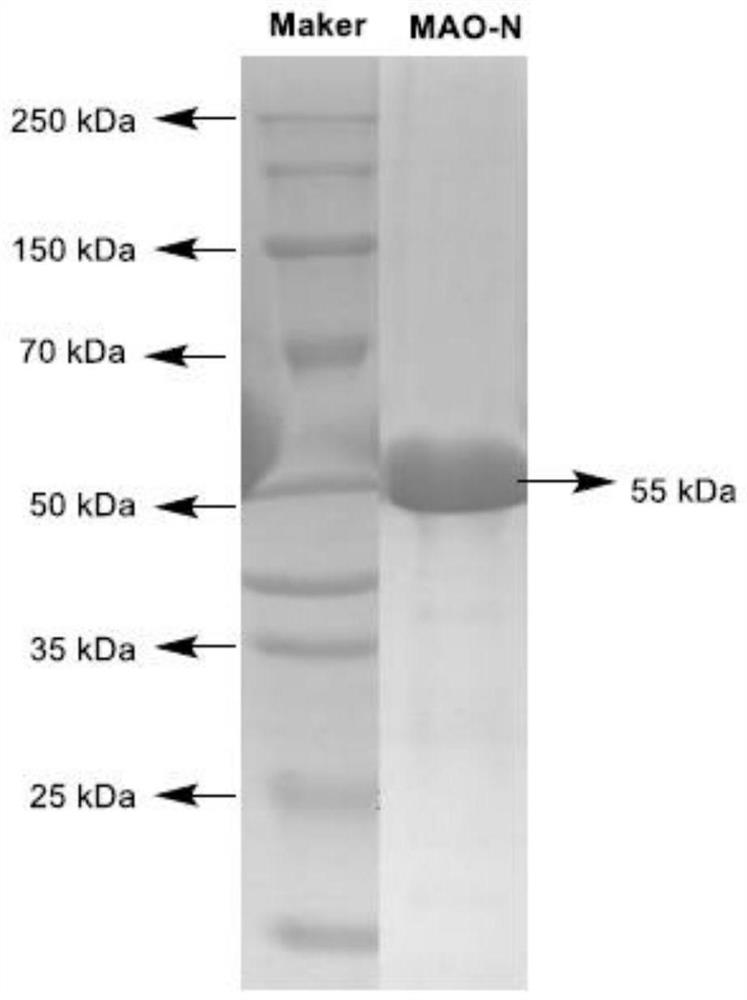

[0029] Example 2: Heterologous expression of monoamine oxidase

[0030] Pick the monoclonal transformants obtained in Example 1 and inoculate them into 4mL LB (containing 50 μg / mL kanamycin antibiotic), and cultivate them at 37°C until OD 600 =0.6, transferred to 400mL LB (containing 50μg / mL kanamycin antibiotic), cultured on a shaker at 37°C until OD 600 =0.6, add isopropyl-β-D-thiogalactoside (IPTG) at a final concentration of 0.1 mM, and induce expression at 18° C. for 18-20 h.

Embodiment 3

[0031] Example 3: Biotransformation of 4-(1-methyl-2-pyrrolidinyl)-3-oxobutanoic acid to produce tropinone

[0032] Take the bacterial strain that has completed heterologous expression in Example 2, collect the bacteria by centrifugation, resuspend with 4 mL of M9 medium, and add the substrate 4-(1-methyl-2-pyrrolidinyl)-3- Oxobutyric acid, transformed at 4°C for 120 hours, added 8 mL of ethyl acetate, extracted, centrifuged to take the supernatant ethyl acetate layer, evaporated to dryness and resuspended with 1 mL of acetonitrile, centrifuged to take the supernatant to detect the formation of tropinone by LC-MS (Mass spectrometry results such as Figure 4 ), the results showed that the conversion rate of this reaction was as high as 90%.

[0033] LC-MS detection conditions:

[0034] Instrument: SHIMADZU LCMS-2020UPLC-MS;

[0035] Analytical column: R227-32015-03Shim-pack Velox Biphenyl (2.7μm, 2.1x100 mm, Shimadzu Corporation), the flow rate is 0.4mL min -1 , the detecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com