Method for preparing hydrogen from coke oven gas by regenerating decarburization liquid by using desorption gas

A coke oven gas and gas analysis technology, which is applied in the chemical industry, can solve problems such as environmental pollution and energy waste, and achieve the effects of avoiding waste, saving equipment investment, saving electricity and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

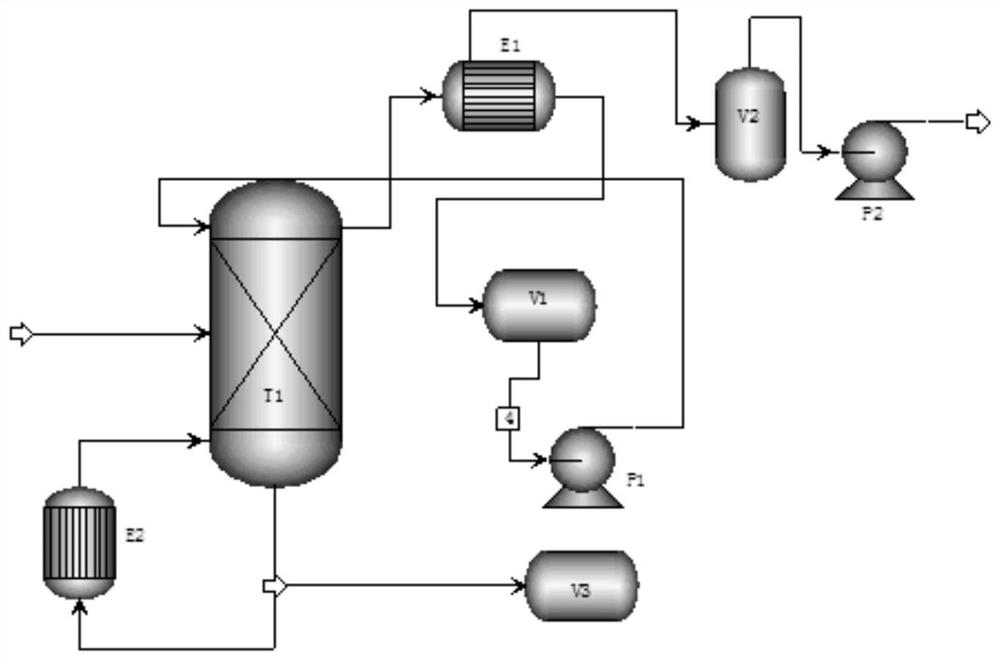

[0100] refer to Figure 4 , the present embodiment provides a system for producing hydrogen from coke oven gas that utilizes analytical gas for decarburization liquid regeneration, specifically including:

[0101] Coke oven gas separator 1: the desulfurized coke oven gas pipeline A is connected to the coke oven gas separator 1, and the coke oven gas separator 1 leads to the condensate pipeline K and the dry desulfurized coke oven gas pipeline B, the dry desulfurized coke oven gas pipeline B is connected to the lower entrance of the absorption tower 2;

[0102] Absorption tower 2: It is an absorption tower with a built-in packing layer. The lower inlet is connected to the dry desulfurized coke oven gas pipeline B, the upper inlet is connected to the propylene carbonate lean liquid pipeline D, and the top outlet is connected to the CO removal 2 The final coke oven gas pipeline C is connected, and the bottom outlet is connected with the propylene carbonate rich liquid pipeline E...

Embodiment 2

[0111] Example 2, this example provides a specific method for producing hydrogen from coke oven gas that utilizes analytic gas for decarburization liquid regeneration, and the implementation of this method uses the system shown in Example 1.

[0112] The coke oven gas comes out of the gas tank, after being compressed once, it passes through the electric tar catcher to remove impurities such as tar and dust, and then it is sent out from the electric tar catcher, and after the second compression, it enters the TSA temperature swing adsorption to further remove benzene, naphthalene and tar and other impurities, so that the impurities of each component of the product gas are controlled at 10mg / m 3 Then enter the conversion cooling process to remove carbon monoxide, and then the gas enters the desulfurization device to remove most of the inorganic sulfur and a small amount of organic sulfur. After the desulfurized coke oven gas is compressed three times by the compressor, it enters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com