CPP tangle film and production process thereof

A production process and conjunctival technology, which is applied in the field of CPP twisted conjunctiva and its production process, can solve problems such as irreversibility, and achieve the effects of improving crystallization properties, lasting antibacterial properties, and increasing nucleation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

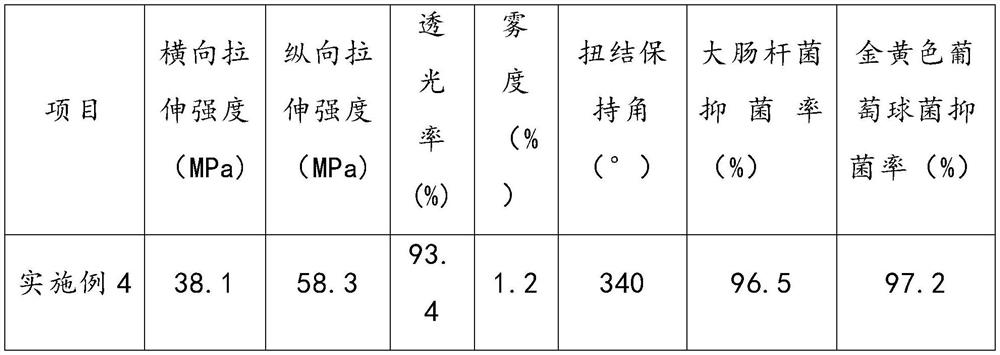

Examples

Embodiment 1

[0028] The present embodiment provides a kind of composite nucleating agent, is made by the following steps:

[0029] Step A1, ultrasonically disperse 7g of nano-mesoporous silica in 200mL of methanol, then add 1.4g of sodium 2,2'-methylenebis(4,6-di-tert-butylphenyl)phosphate, and stir at room temperature After 6 hours, the reaction product was evaporated to dryness at 80°C to obtain filled silica;

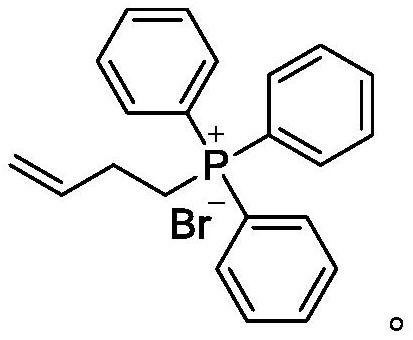

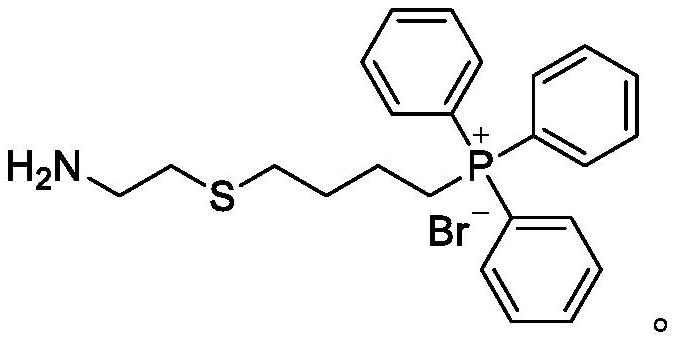

[0030] Step A2. Add 5.8g of filled silica, 50mL of absolute ethanol and 50mL of deionized water into a three-necked flask, ultrasonically disperse at a frequency of 40kHz for 20min, add 2.3g of KH-560, and stir for 6h at a speed of 200r / min. Add 7.8g of quaternary phosphonium salt modifier, stir and react for 2 hours at room temperature, after the reaction, centrifuge at 1000r / min for 10min, wash the precipitate with deionized water for 3 times, and finally dry it in an oven at 80°C to constant weight. A composite nucleating agent is obtained.

[0031] Wherein, the quaternary p...

Embodiment 2

[0035] The present embodiment provides a kind of composite nucleating agent, is made by the following steps:

[0036]Step A1, ultrasonically disperse 7g of nano-mesoporous silica in 200mL of methanol, then add 1.4g of sodium 2,2'-methylenebis(4,6-di-tert-butylphenyl)phosphate, and stir at room temperature for 6h Finally, the reaction product was evaporated to dryness at 80°C to obtain filled silica;

[0037] Step A2: Add 6.0g of filled silica, 70mL of absolute ethanol and 52mL of deionized water into a three-necked flask, ultrasonically disperse at a frequency of 45kHz for 30min, add 2.5g of KH-560, stir and react at a speed of 250r / min for 7h, then add 7.9g of quaternary phosphonium salt modifier, stirred and reacted for 3h at room temperature, after the reaction, centrifuged at 1200r / min for 10min, the precipitate was washed 4 times with deionized water, and finally dried in an oven at 80°C to constant weight to obtain Composite nucleating agent.

[0038] Wherein, the quat...

Embodiment 3

[0042] The present embodiment provides a kind of composite nucleating agent, is made by the following steps:

[0043] Step A1, ultrasonically disperse 7g of nano-mesoporous silica in 200mL of methanol, then add 1.4g of sodium 2,2'-methylenebis(4,6-di-tert-butylphenyl)phosphate, and stir at room temperature After 6 hours, the reaction product was evaporated to dryness at 80°C to obtain filled silica;

[0044] Step A2: Add 6.2g of filled silica, 80mL of absolute ethanol and 55mL of deionized water into a three-necked flask, ultrasonically disperse at a frequency of 50kHz for 40min, add 2.6g of KH-560, stir and react at a speed of 300r / min for 8h, then add 8.1g of quaternary phosphonium salt modifier, stirred and reacted for 4h at room temperature, after the reaction, centrifuged at 1500r / min for 10min, the precipitate was washed 5 times with deionized water, and finally dried in an oven at 80°C to constant weight to obtain Composite nucleating agent.

[0045] Wherein, the quat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com