Short fiber polyaniline and application thereof in water-based heavy anti-corrosion coating

A technology of polyaniline and short fibers, which is applied in anti-corrosion coatings, fiber chemical characteristics, coatings, etc., can solve the problems of difficult dispersion of composite particles, high CNT content, and increase the preparation cost of functional additive materials, and achieve excellent long-term anti-corrosion performance , excellent adhesion, and the effect of increasing electron transport performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 0.93 g of aniline and a CNT containing 0.0093 g, adding the ultrasonic dispersion in a beaker, then adding a concentrated hydrochloric acid solution to 1, transferring a mixture into a three-neck flask, add 150 mL of deionized water, and use ice water bath The system temperature is at 0-5 ° C. 2.74 g of ammonium sulfate was sued with 10 ml of deionized water, and the drip funnel was added, and the reaction system was added to the reaction system in 30 minutes, and the reaction was added to the reaction for 16 h. After filtration of the mixed system, it was washed 3 times with ethanol and deionized water, and the short fiber morphology PANI (1% CNT) was dried.

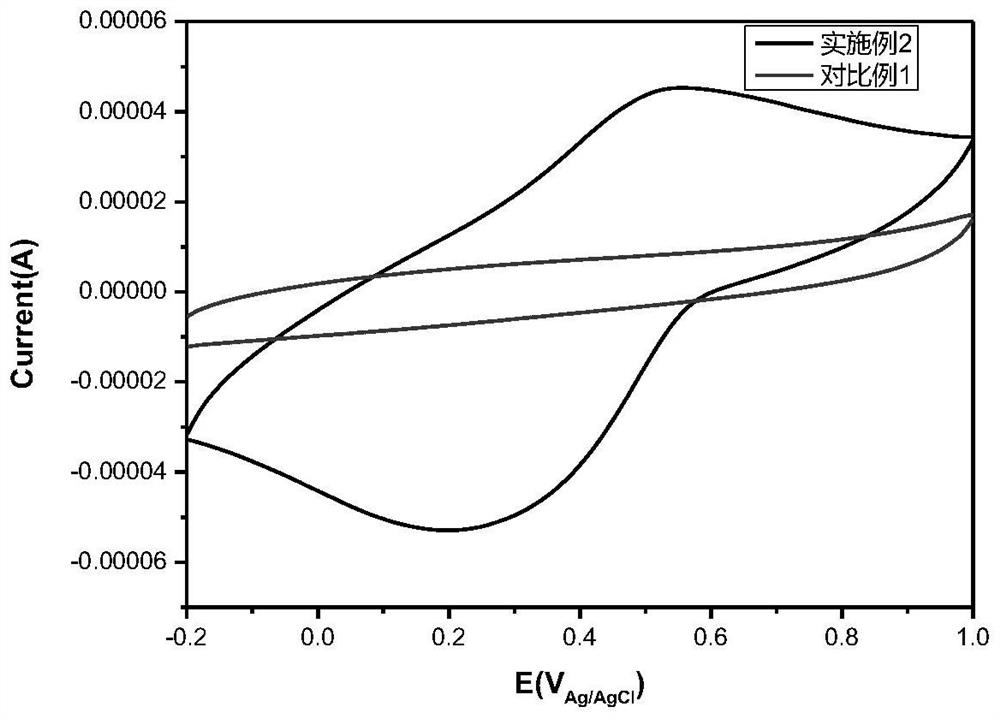

Embodiment 2

[0030] The 0.93 g of aniline and a CNT containing 0.028 g were added to the beaker, and then the concentrated hydrochloric acid solution was adjusted to 1, and the mixture was transferred to a three-necked flask, and 150 ml of deionized water was added, and the ice water bath was added. The system temperature is at 0-5 ° C. 2.74 g of ammonium sulfate is dissolved with 10 ml of deionized water, and the drip funnel was added, and the reaction system was added to the reaction system in 30 minutes, and the reaction was added to the reaction for 24 h. After filtration of the mixed system, it was washed 3 times with ethanol and deionized water, and dried to obtain a short fiber morphology PANI (3% CNT).

Embodiment 3

[0032] It is weighed with 0.93 g of aniline and a CNT containing 0.047 g, and the ultrasonic dispersion of the beaker was added. Subsequently, the concentrated hydrochloric acid solution was adjusted to 1, and the mixture was transferred to the three-neck flask, and 150 ml of deionized water was added, and the water bath was added. The system temperature is at 0-5 ° C. 2.74 g of ammonium sulfate is dissolved with 10 ml of deionized water, and the drip funnel was added, and the reaction system was added to the reaction system in 30 minutes, and the reaction was added to the reaction for 24 h. After filtration of the mixed system, the mixture was washed 3 times with ethanol and deionized water, dried to obtain a short fiber morphology PANI (5% CNT).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com