Method for utilizing byproduct sodium chloride in industrial production of dimethyl diallyl ammonium chloride in cationic emulsion

A technology of dimethyl diallyl ammonium chloride and cationic emulsion, which is applied in the preparation of cationic emulsion and the application of industrial by-product sodium chloride in cationic emulsion, which can solve the problem of product demulsification and gelling, and negative benefits of enterprises , increasing the amount of emulsion used, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

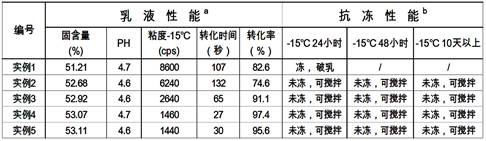

Examples

Embodiment 1

[0020] The specific operation is as follows:

[0021] (1) Water phase preparation: add 410 grams of acryloyloxyethyltrimethylammonium chloride and 225 grams of acrylamide to 75 grams of deionized water and mix, add 12 grams of oxalic acid, and fully dissolve it with the monomer Mix, adjust pH to 4.6 with 48% sodium hydroxide, add 1 gram of sodium bromate, 0.3 gram of pentasodium diethylenetriaminepentaacetic acid, 0.008 gram of sodium hypophosphite, 0.016 gram of anhydrous copper sulfate, 0.05 gram of the third monomer N, N-methylenebisacrylamide, fully stirred and dissolved to obtain an aqueous phase;

[0022] (2) Oil phase preparation: Weigh 250 grams of white oil, add 36 grams of compounded surfactant (Span60 / Tween60 is 2.5:1) under stirring, and mix well to obtain a clear oil phase;

[0023] (3) Preparation of emulsion: Slowly add the water phase to the rapidly stirring oil phase, and stir for 5 minutes after the addition. Use a high-power emulsification pump to perform ...

Embodiment 2

[0027] The specific operation is as follows:

[0028] (1) Water phase preparation: add 428 grams of acryloyloxyethyltrimethylammonium chloride and 214 grams of acrylamide to 65 grams of deionized water and mix, add 12 grams of oxalic acid and 45 grams of by-product sodium chloride , fully dissolve and mix it with the monomer, adjust the pH to 4.3 with 48% sodium hydroxide, add 0.9 grams of sodium bromate, 0.3 grams of pentasodium diethylenetriaminepentaacetic acid, 0.007 grams of sodium hypophosphite, and 0.016 grams of anhydrous sulfuric acid Copper, 0.05 g of the third monomer N, N-methylenebisacrylamide, fully stirred and dissolved to obtain an aqueous phase;

[0029] (2) Oil phase preparation: Weigh 250 grams of white oil, add 36 grams of compounded surfactant (Span60 / Tween60 is 2.5:1) under stirring, and mix thoroughly to obtain a clear oil phase;

[0030] (3) Preparation of emulsion: Slowly add the water phase to the rapidly stirring oil phase, and stir for 5 minutes af...

Embodiment 3

[0034] The specific operation is as follows:

[0035](1) Water phase preparation: add 422 grams of acryloyloxyethyltrimethylammonium chloride and 208 grams of acrylamide to 68 grams of deionized water and mix, add 12 grams of oxalic acid and 46 grams of by-product sodium chloride , fully dissolve and mix it with the monomer, adjust the pH to 4.4 with 48% sodium hydroxide, add 1 gram of sodium bromate, 0.3 gram of pentasodium diethylenetriaminepentaacetic acid, 0.009 gram of sodium hypophosphite, and 0.016 gram of anhydrous sulfuric acid Copper, 0.05 g of the third monomer N, N-methylenebisacrylamide, fully stirred and dissolved to obtain an aqueous phase;

[0036] (2) Oil phase preparation: Weigh 240 grams of white oil, add 36 grams of compounded surfactant (Span60 / Tween60 is 2.5:1), 10 grams of (Z)-N,N-di(2-hydroxy Ethyl)-9-octadecenoic acid amide, mixed well to obtain a clear oil phase;

[0037] (3) Preparation of emulsion: Slowly add the water phase to the rapidly stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com