Method for preparing high-compaction lithium manganese iron phosphate by explosion method

A technology for solidifying lithium iron manganese phosphate and lithium iron manganese phosphate is applied in the field of preparing high-pressure lithium iron manganese phosphate by an explosion method, and can solve the problems of poor electrochemical performance and energy density of lithium iron manganese phosphate, and compaction density of lithium iron manganese phosphate. problems such as poor lithium iron manganese phosphate and large particle size of lithium iron manganese phosphate, to achieve the effect of facilitating large-scale preparation, improving electrochemical performance and energy density, and improving compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

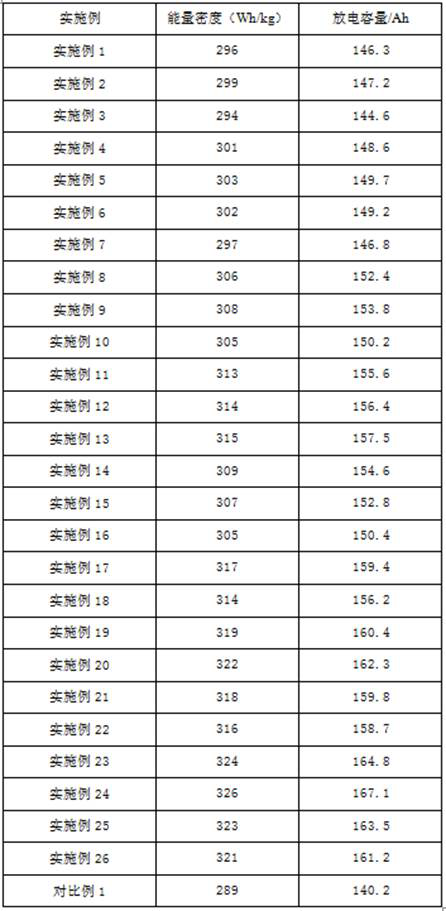

Examples

Embodiment 1

[0044] A method for preparing high-pressure lithium iron manganese phosphate by explosive method, the lithium iron manganese phosphate molecular formula LiMn x Fe 1-x PO 4 , the preparation method comprises the following steps:

[0045] S1. Preparation of precursor powder:

[0046] (1) Take 0.5mol of lithium source, 0.5mol of iron phosphate and 0.5mol of manganese source, place lithium source, iron phosphate and manganese source in the ratio of n(lithium source) / n(iron phosphate + manganese source)=0.5 In the ball mill tank, add zirconium beads and 50kg of mixed medium, seal it and place it in a ball mill, and after ball milling at a speed of 200r / min at room temperature for 2 hours, the mixed material is obtained; the mixed medium is tap water; the lithium source is carbonic acid Lithium; The manganese source is manganese carbonate;

[0047] (2) Put the mixed material in a drying oven, pre-dry it at 60°C and grind it into powder to obtain the precursor powder;

[0048] S...

Embodiment 2

[0057] A method for preparing high-pressure lithium iron manganese phosphate by explosive method, the lithium iron manganese phosphate molecular formula LiMn x Fe 1-x PO 4 , the preparation method comprises the following steps:

[0058] S1. Preparation of precursor powder:

[0059] (1) Take 0.5mol of lithium source, 0.5mol of iron phosphate and 0.5mol of manganese source, place lithium source, iron phosphate and manganese source in the ratio of n(lithium source) / n(iron phosphate + manganese source)=0.5 In the ball mill tank, add zirconium beads and 50kg of mixed medium, seal it and place it in a ball mill, and after ball milling at a speed of 300r / min at room temperature for 6 hours, the mixed material is obtained; the mixed medium is tap water; the lithium source is carbonic acid Lithium; The manganese source is manganese carbonate;

[0060] (2) Put the mixture in a drying oven, pre-dry it at 80°C and grind it into powder to obtain the precursor powder;

[0061] S2. Prep...

Embodiment 3

[0070] A method for preparing high-pressure lithium iron manganese phosphate by explosive method, the lithium iron manganese phosphate molecular formula LiMn x Fe 1-x PO 4 , the preparation method comprises the following steps:

[0071] S1. Preparation of precursor powder:

[0072] (1) Take 0.5mol of lithium source, 0.5mol of iron phosphate and 0.5mol of manganese source, place lithium source, iron phosphate and manganese source in the ratio of n(lithium source) / n(iron phosphate + manganese source)=0.5 In the ball mill tank, add zirconium beads and 50kg mixed medium, seal it and place it in a ball mill, and after ball milling at a speed of 400r / min for 10 hours at room temperature, the mixed material is obtained; the mixed medium is tap water; the lithium source is carbonic acid Lithium; The manganese source is manganese carbonate;

[0073] (2) Put the mixed material in a drying oven, pre-dry it at 100°C and grind it into powder to obtain the precursor powder;

[0074] S2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com