Silicon wafer processing fragmentation device and fragmentation method thereof

A technology of silicon wafers and mounts, applied in conveyor control devices, sorting, transportation and packaging, etc., can solve the problems of increased silicon wafer damage rate, affecting work efficiency, affecting use, etc., to reduce silicon wafer damage and improve Work efficiency and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

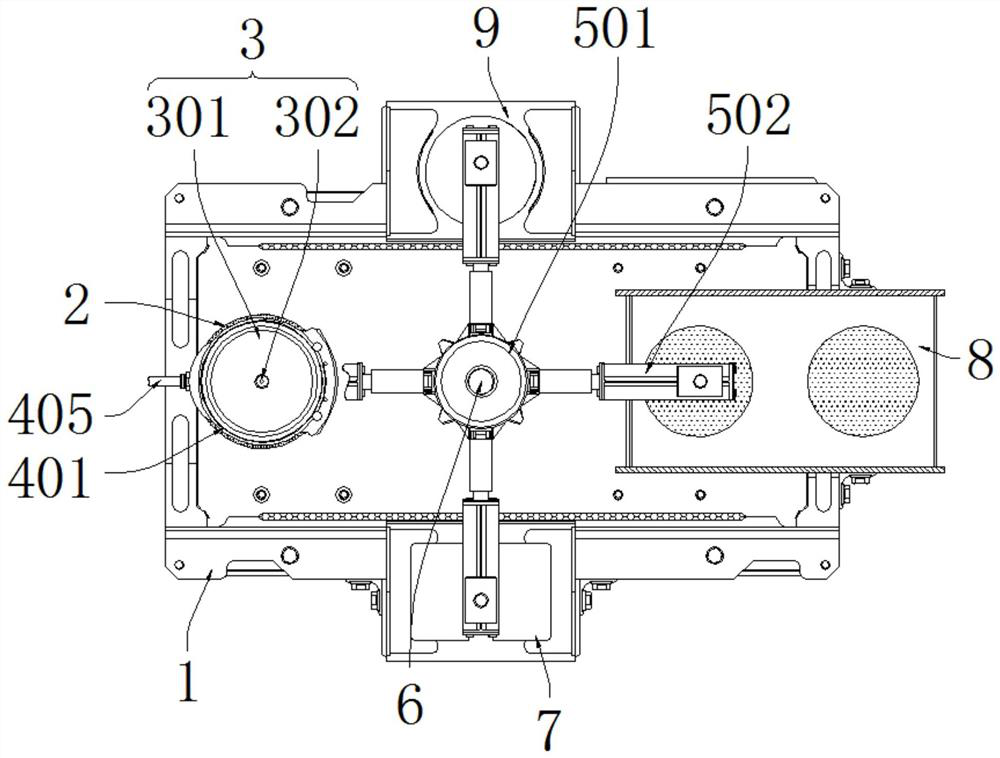

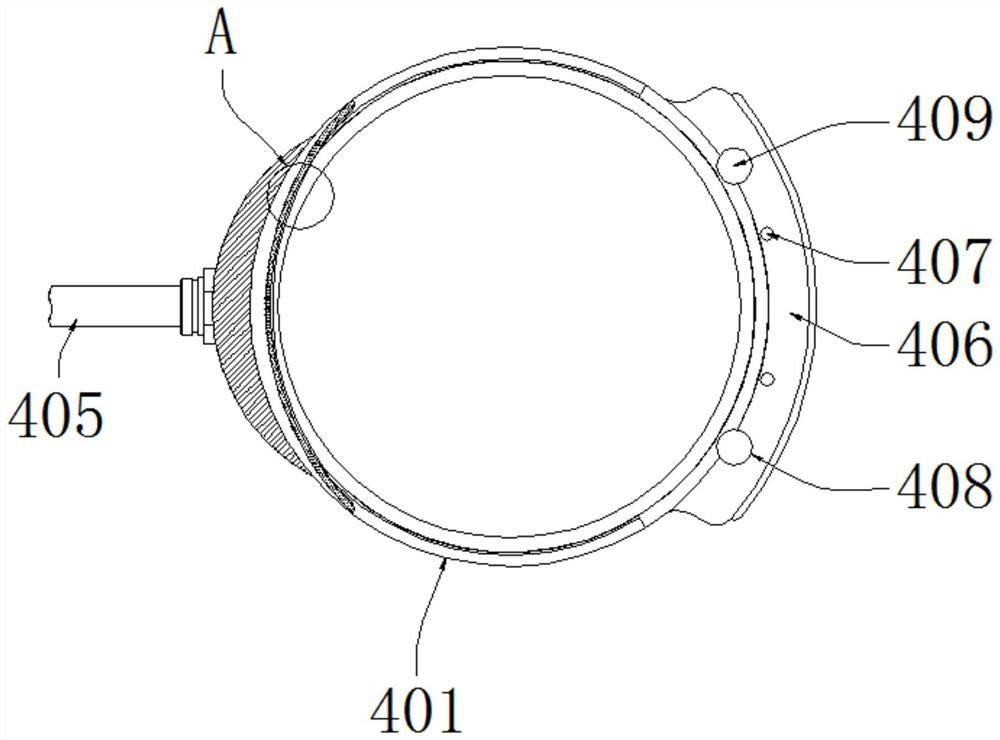

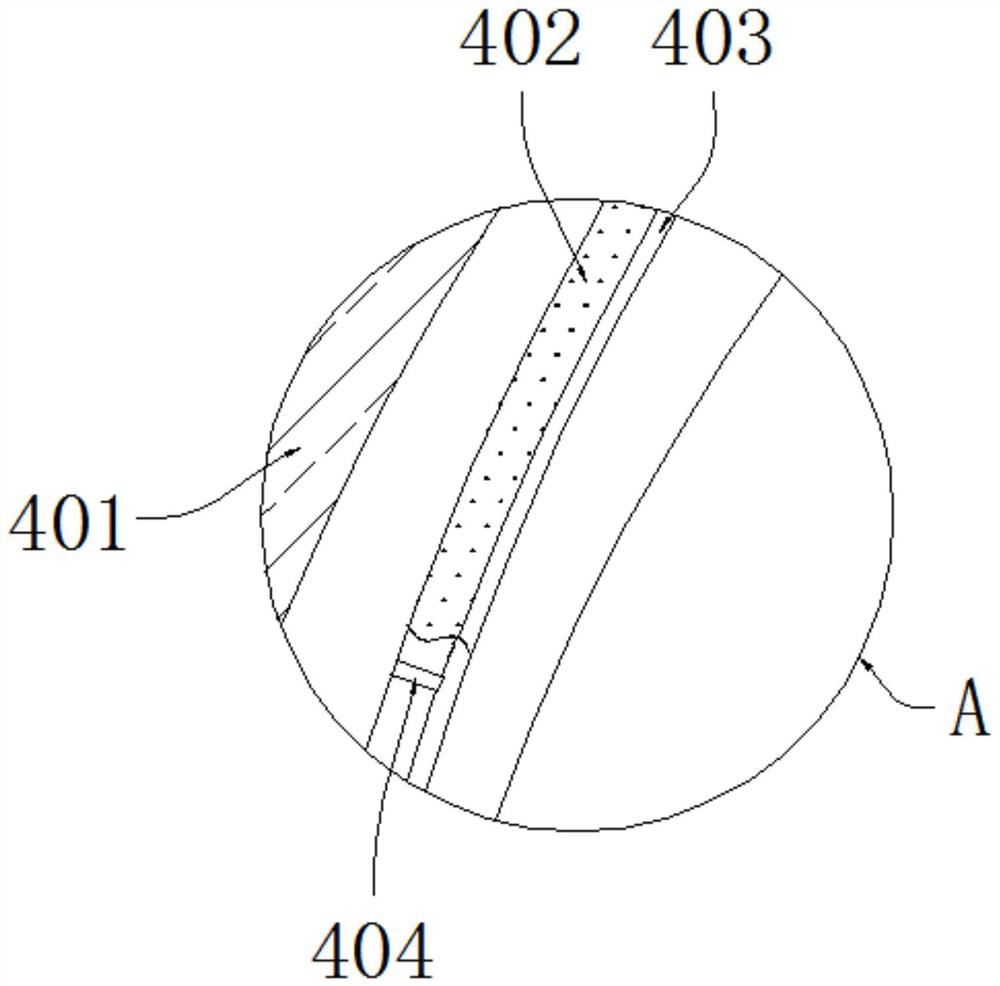

[0038] See Figure 1-7The present invention provides a technical solution: a silicon sheet processing fragmentation device and a fragmentation method thereof, including mounting seat 1 and auxiliary component 5, and a water tank 2 is mounted on the left side of the mount 1, and the water tank 2 is mounted inside. The frame 3, the carriage 3 is mounted, the bracket 3 includes an electric telescoping rod 301 and a dramable disk 302, and the electric telescoping rod 301 is connected to the trap 302, and the fragmentation mechanism 4 includes a set. The frame 401, the drive plate 402, the guide plate 403, the first nozzle 404, and the trachea 405, and the roller 402 is mounted on the left side of the ferrule 401, and the surface of the drive plate 402 is provided with a guide plate 403, and the guide plate 403 is inside. The first air nozzle 404 is mounted, and the air pipe 405 is connected to the right side of the first air nozzle 404, and the auxiliary component 5 is mounted to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com