Accurate control device for carbon fiber impregnation amount

A precise control and carbon fiber technology, applied in the field of precise control devices, can solve the problems of unstable carbon fiber dipping amount, defects in winding products, and unquantifiable dipping amount, etc., to achieve controllable glue viscosity, quantifiable dipping amount, Soaking effect stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

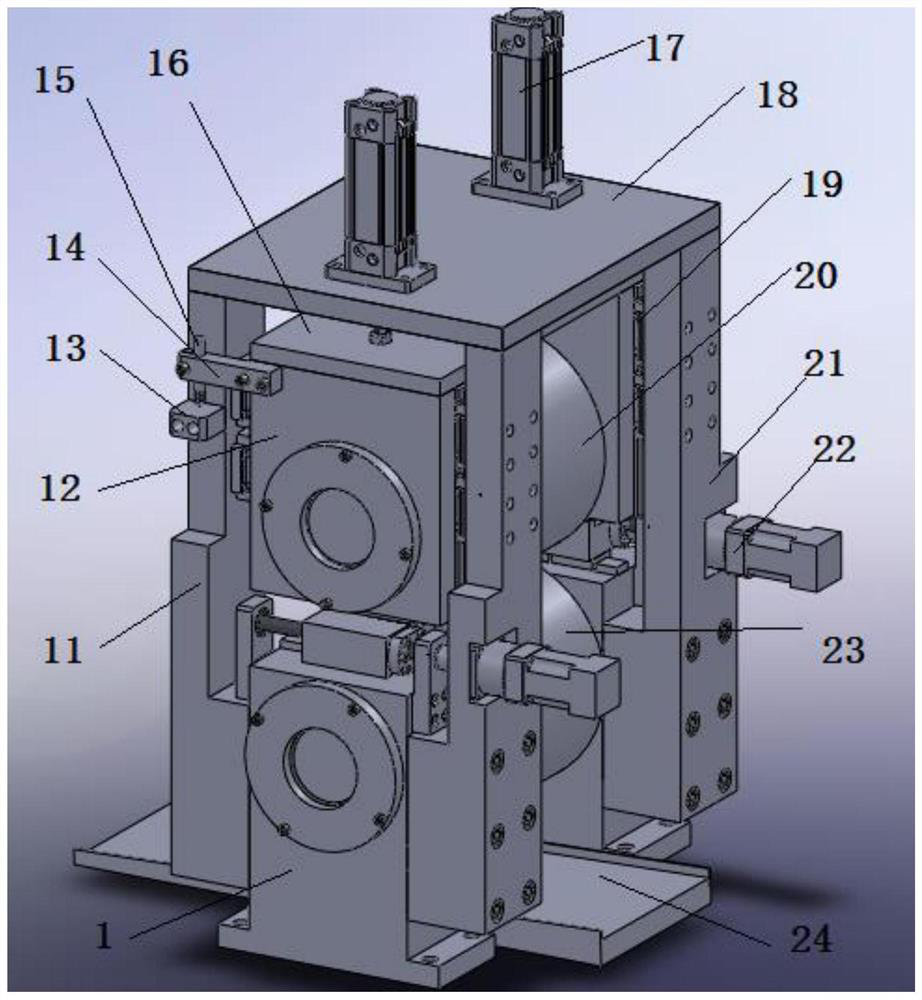

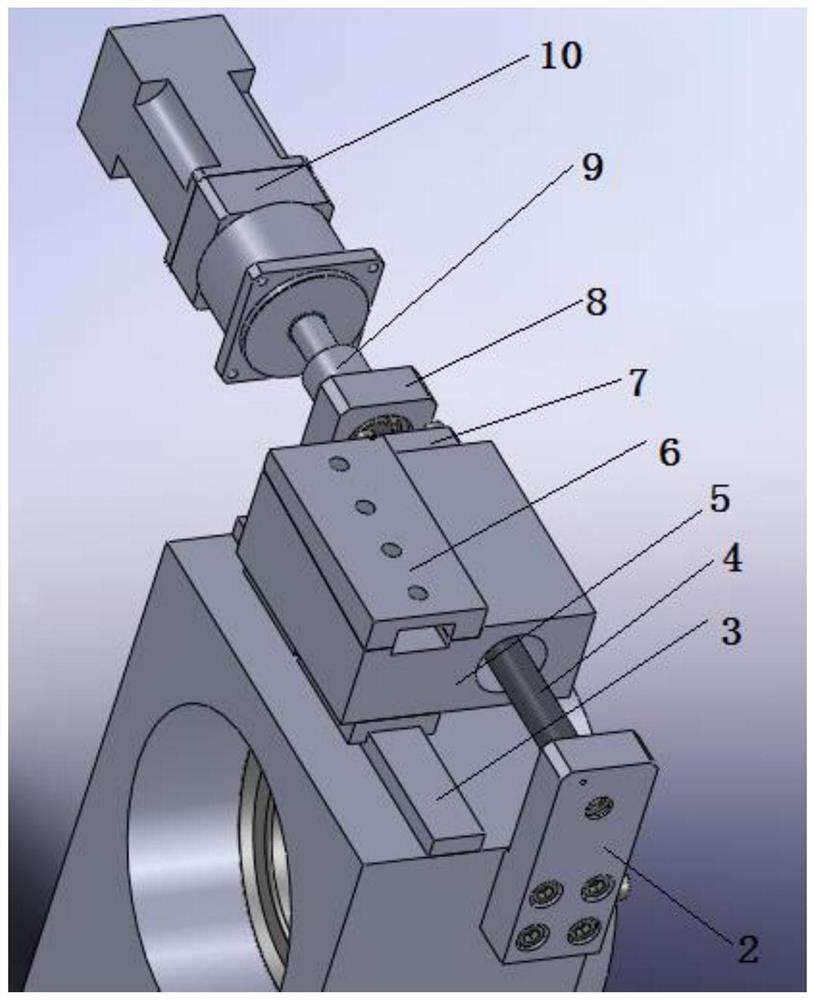

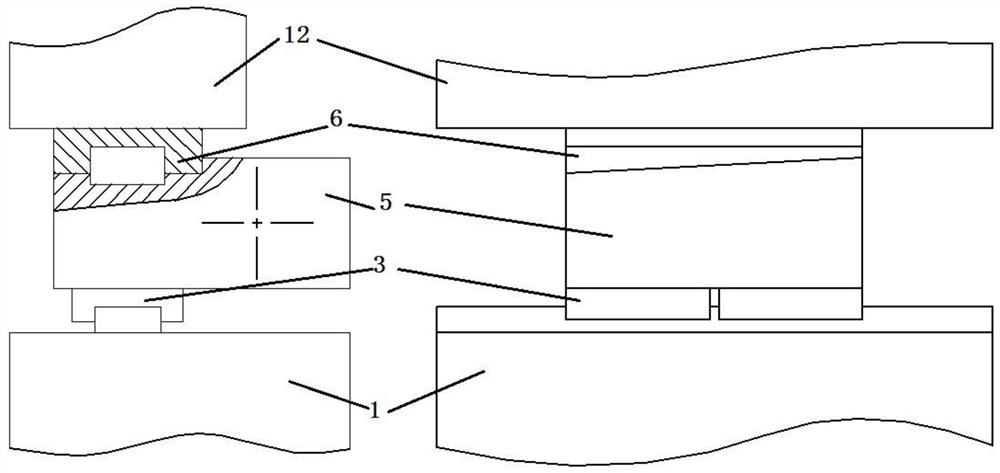

[0008] exist figure 1 In the middle, the roller mechanism is composed of the upper roller portion and the lower roll portion, including the lower roll support (1), the lower roll (23), the rail base 1 (11), the upper roll support (12), a compression cable plate (16), upper plate (18), linear rail sub (19), upper roller (20), rail pedestal 2 (21), a glue groove (24), cylinder (17); lower roll support (1) There are two, for the main foundation of the entire unit, the internal bearing, spacer, end cover, retaining ring, sealing ring and other components, is attached to the appropriate position of the wound device dip system, and provide both ends of the lower roller (23). Support and make it free to rotate; there are two pieces of rail base 1 (11), which are mounted on one side of the two lower roll holders (1), and there are two pieces of rail base 2 (21), respectively, respectively. On the other side of the lower roll support (1), the rail base 1 (11) and the rail base 2 (21) are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com