A head and tail yarn automatic isolation system

A technology of isolation system and head and tail filaments, which is applied in the direction of filament generation, spinneret assembly, textiles and papermaking, etc., can solve the problems of large application restrictions and poor detection effect of head and tail filaments, and achieve small application restrictions and benefit Productivity and the effect of expanding the range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

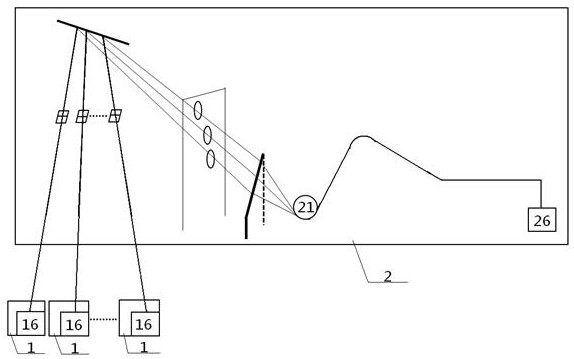

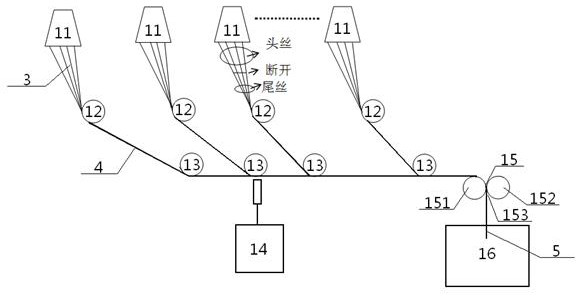

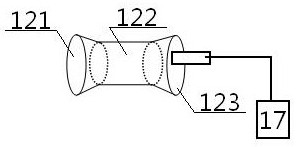

[0046] see Figure 1 to Figure 4 , an automatic isolation system for head and tail threads; the automatic isolation system includes a front unit 1 and a rear unit 2, a single rear unit 2 corresponds to at least two front units 1, and only one container is arranged in a single front unit 1 Silk barrel 16; the pre-unit 1 includes a raw silk nozzle 11, a godet wheel 12, a threading device 14, a traction wheel 15 and a silk barrel 16, and the number of the raw silk nozzle 11 and the godet wheel 12 is multiple , and one-to-one correspondence; the downstream of the raw silk nozzle 11 is a godet 12, the godet 12 is provided with a speed detection device 17, the downstream of the godet 12 is a traction wheel 15, and the downstream of the traction wheel 15 is Silk barrel 16; the rear unit 2 includes a cluster wheel 21, the first drafting wheel 22 and a packing device 26, the upstream of the cluster wheel 21 is the silk barrel 16 in the front unit 1, and the downstream of the cluster wh...

Embodiment 2

[0048] Basic content is the same as embodiment 1, the difference is:

[0049] Be provided with bunching wheel 13 between described godet wheel 12 and traction wheel 15, the quantity of bunching wheel 13 corresponds to godet wheel 12 one by one, the downstream of godet wheel 12 is bunching wheel 13, and this bunching wheel The downstream of 13 is traction wheel 15. The spinning-in device 14 is arranged close to the raw silk spraying head 11 .

Embodiment 3

[0051] Basic content is the same as embodiment 1, the difference is:

[0052] Below the first drafting wheel 22, a counter 27 for the number of rotations is arranged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com