Cast-in-place double-sided fair-faced concrete wall structure and construction method thereof

A technology of fair-faced concrete and construction method, applied in the direction of walls, building components, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

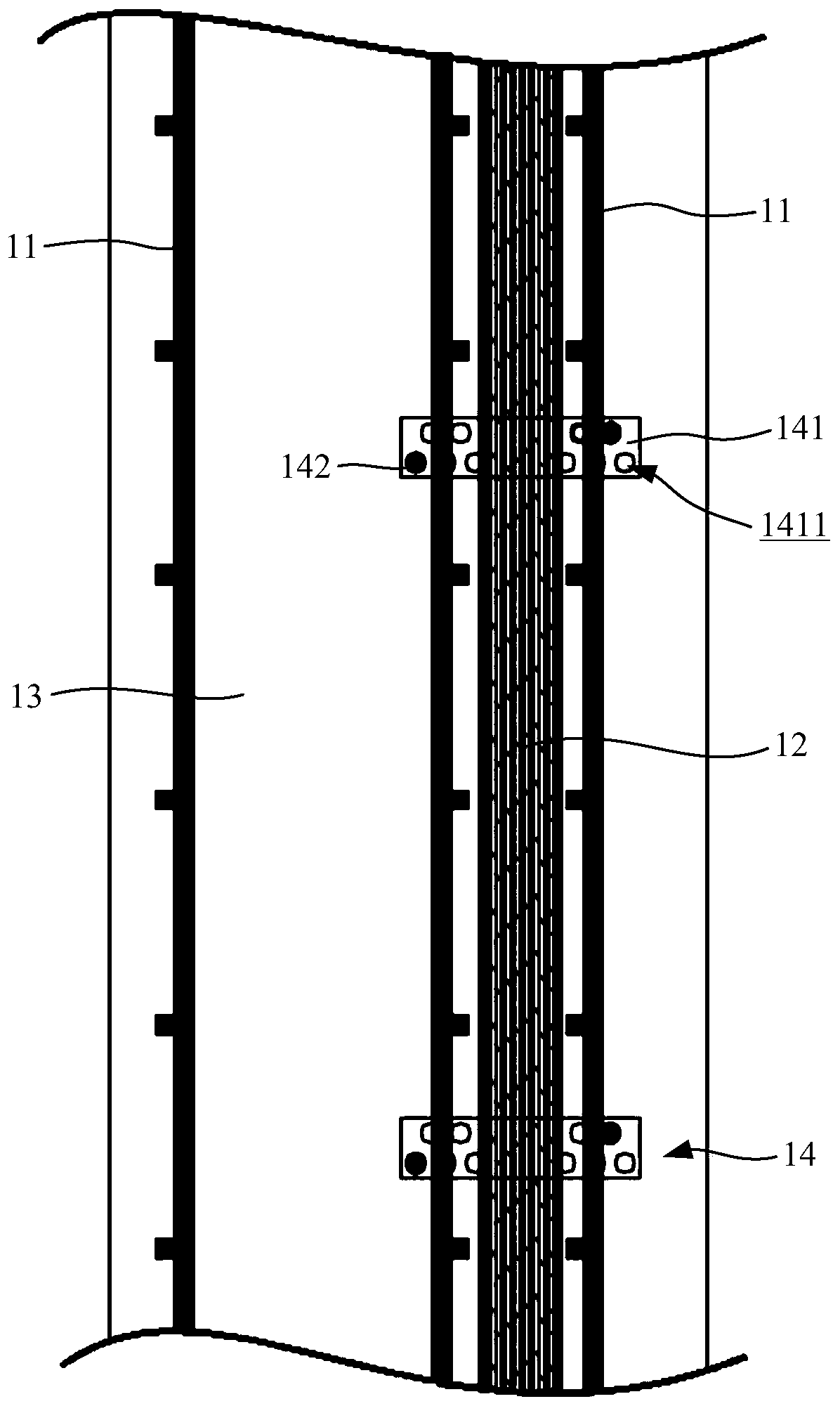

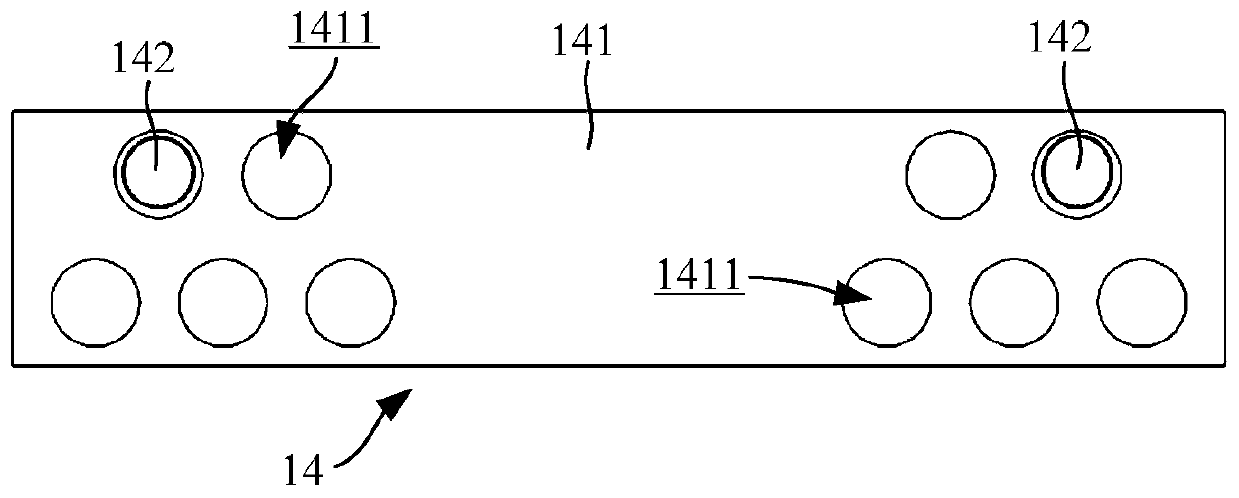

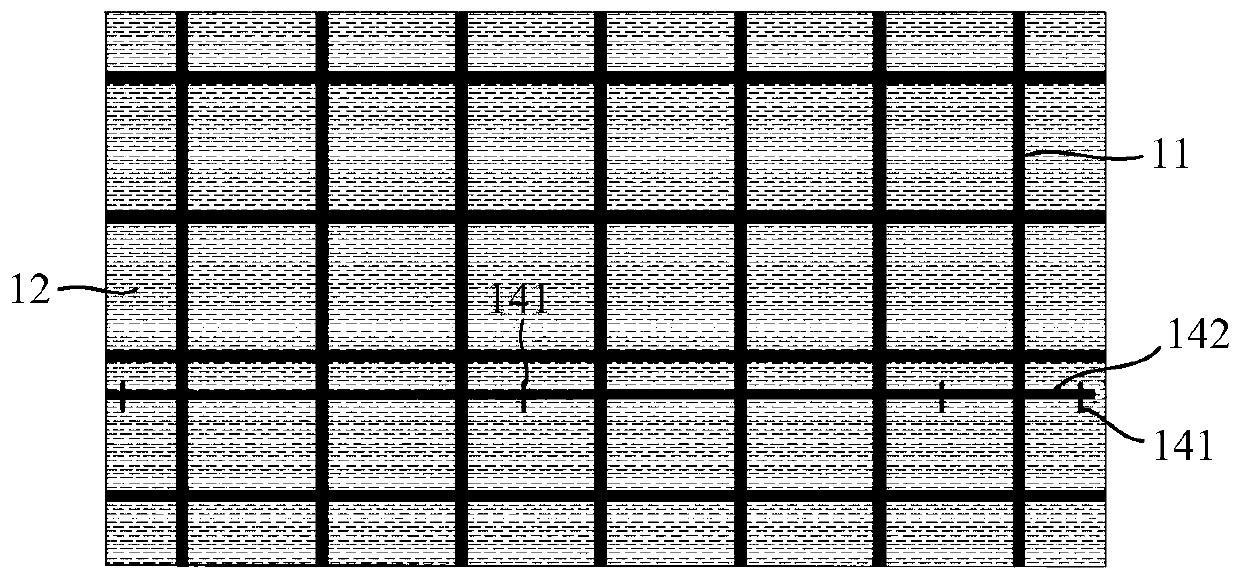

[0030] refer to figure 1 , the present invention provides a kind of cast-in-situ double-sided fair-faced concrete wall structure and its construction method, by sandwiching the insulation board between the steel skeletons, and then integrally pouring the fair-faced concrete on both sides of the insulation board to form the fair-faced concrete wall, Both the steel frame and the insulation board are buried in the fair-faced concrete wall, that is, the entire wall is completed by cast-in-place, and there is no need to pour half of the wall first, and then pour the remaining half of the wall after laying the insulation board, which solves the difficulty The problem of pouring to form a double-sided clear-faced concrete wall makes both sides of the wall have a clear-water effect, and can be poured in one piece to form a double-sided clear-faced conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com