A regional energy station co-built with a substation

A technology of energy stations and substations, applied in the field of energy stations, can solve the problems of energy stations occupying a large space, poor switching stability, and affecting the use effect, so as to meet the energy supply requirements and improve the stability of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention provides a regional energy station jointly built with a substation, which adopts the joint construction method of the energy station and the substation, such as Figure 11As shown, the substation is set on the ground, one side of the substation is the main transformer room, and the other side is a three-story construction design, in which each floor is reasonably arranged with a 10kV switch room (including grounding transformers, small resistance complete sets of devices and high-voltage cable shafts) , 10kV reactor room, 110kV GIS room, capacitor room, fire control room, secondary equipment room, battery room, office room and toilet, etc. Among them, the necessary space is designated as the power distribution room of the energy station, office room, etc.

[0040] Under the substation, the basement level and the second basement level are respectively set up. The basement level includes a cable interlayer, a fire protection water layer and a pump ro...

Embodiment 2

[0050] On the basis of the combined regional energy station in Embodiment 1, this embodiment puts the energy supply system in a separate cooling mode, and its operation mode is specifically:

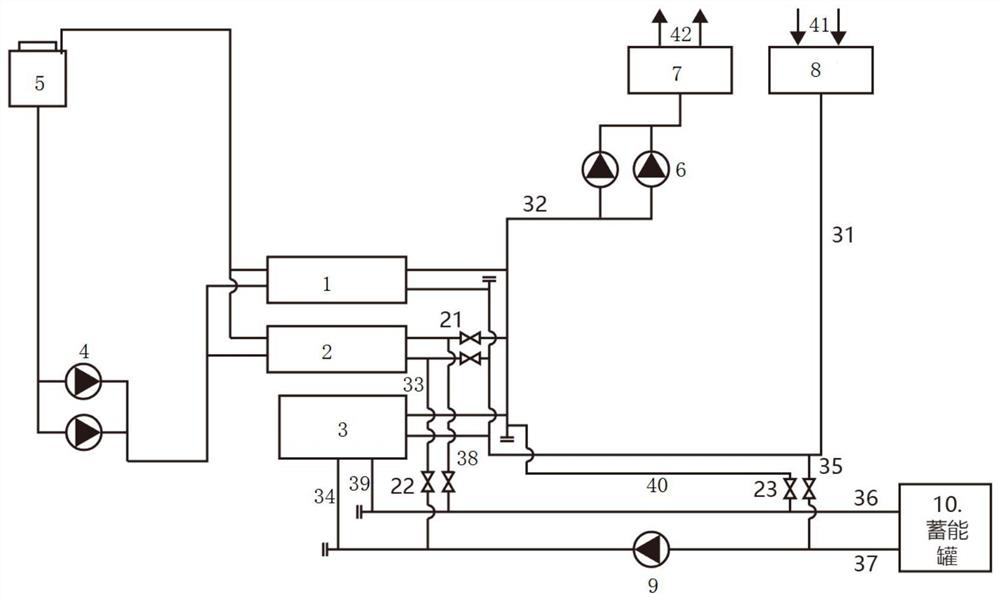

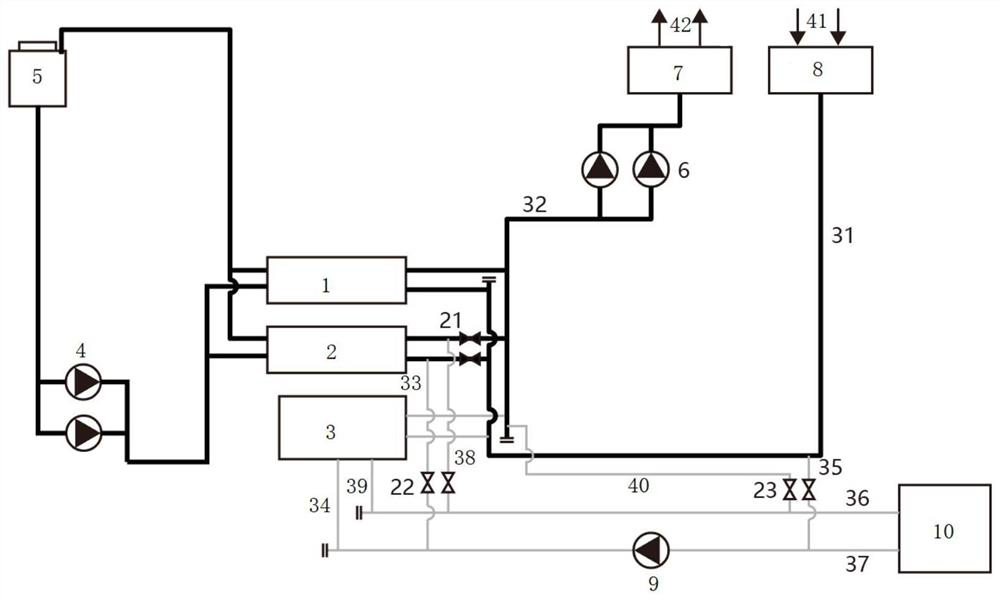

[0051] like figure 2 As shown, put the first centrifugal unit 1, the second centrifugal unit 2, the cooling pump 4, the cooling tower group 5, the cold-temperature pump 6, the water separator 7, and the water collector 8 into the running state, and put the electrode boiler 3, the energy storage pump 9 and the energy storage tank 10 are set to the non-operating state; then the first cold storage switching valve group 21 is opened, the second cold storage switching valve group 22 is closed, and the energy discharge switching valve group 23 is closed.

[0052] The trajectory of the individual refrigeration process of the energy supply system is as follows: figure 2 As shown by the bold line in , specifically:

[0053] The chilled water return water with high temperature at the user end ...

Embodiment 3

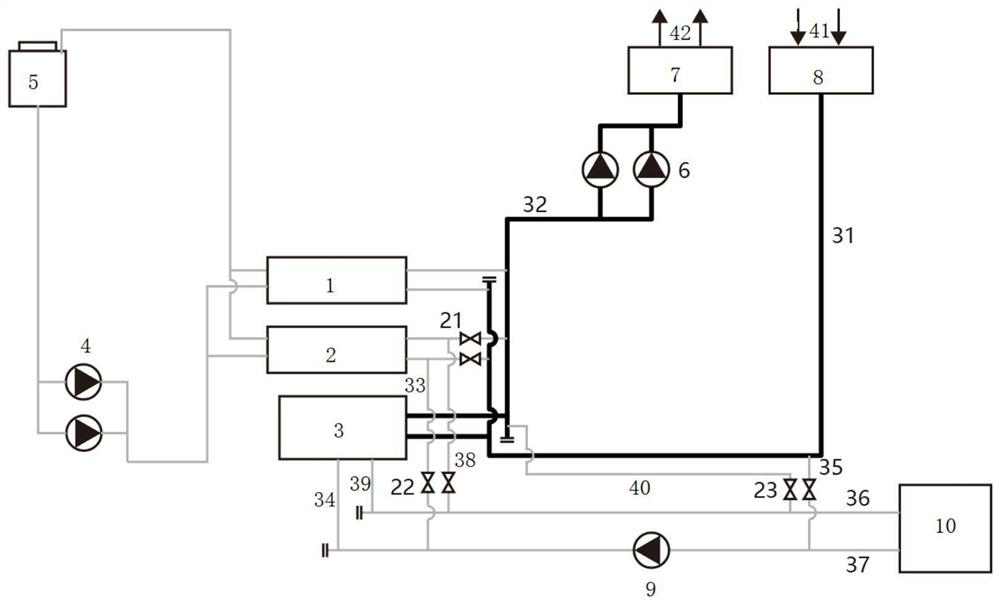

[0055] On the basis of the co-constructed regional energy station in Embodiment 1, this embodiment puts the energy supply system in a separate heating mode, and its operation mode is specifically:

[0056] like image 3 As shown, the electrode boiler 3, the cold and warm pump 6, the water separator 7, and the water collector 8 are put into operation, and the first centrifugal unit 1, the second centrifugal unit 2, the cooling pump 4, the cooling tower group 5, and the energy storage pump 9 and the energy storage tank 10 are set to the non-operating state; the first cold storage switching valve group 21 is closed, the second cold storage switching valve group 22 is closed, and the energy discharge switching valve group 23 is closed.

[0057] The individual heating process trajectory of the energy supply system is as follows: image 3 As shown by the bold line in , specifically:

[0058] The hot water return water with a lower temperature at the user end passes through the ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com