Blowout wreaking equipment for driving well

An equipment and cone technology, applied in the field of steam flooding well blowout devices, can solve the problems of high temperature expansion, hydrogen sulfide aging, and difficult operation, and achieve the effects of eliminating constraints, ensuring construction safety, and reducing well control risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

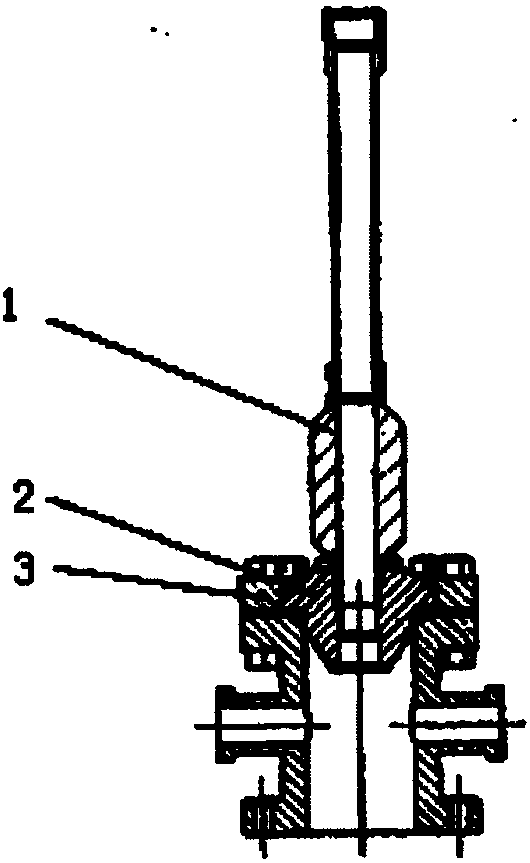

[0007] see figure 1 , a kind of spraying equipment for well flooding, which is composed of a cock valve 1, a tubing hanging cone 2 and a split flange 3; the cock valve 1 is connected with the tubing hanging cone 2 with threads, and the lower end of the tubing hanging cone 2 is connected to the tubing Threaded connection, the lower end of the oil pipe hanging cone 2 is cone-shaped, and the upper end is covered with a split flange 3, and the oil pipe hanging cone 2 is made of high temperature resistant and anti-aging metal materials.

[0008] After the present invention is connected with the oil pipe, it realizes the action of running continuously by directly lowering. Utilize the guidance and righting of the oil pipe hanging cone 2 to force the oil pipe to be automatically centered, and then complete the steel ring into the groove. Use the split flange 3 to rotate the flange surface at will, align the upper and lower screw holes, and quickly tighten the wellhead screw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com