Continuous wax dispersing groove

A wax spotting and wax storage technology, used in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problem of large intensity of wax sealing operations, and achieve the effect of improving the fixing effect, small size, and compact overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

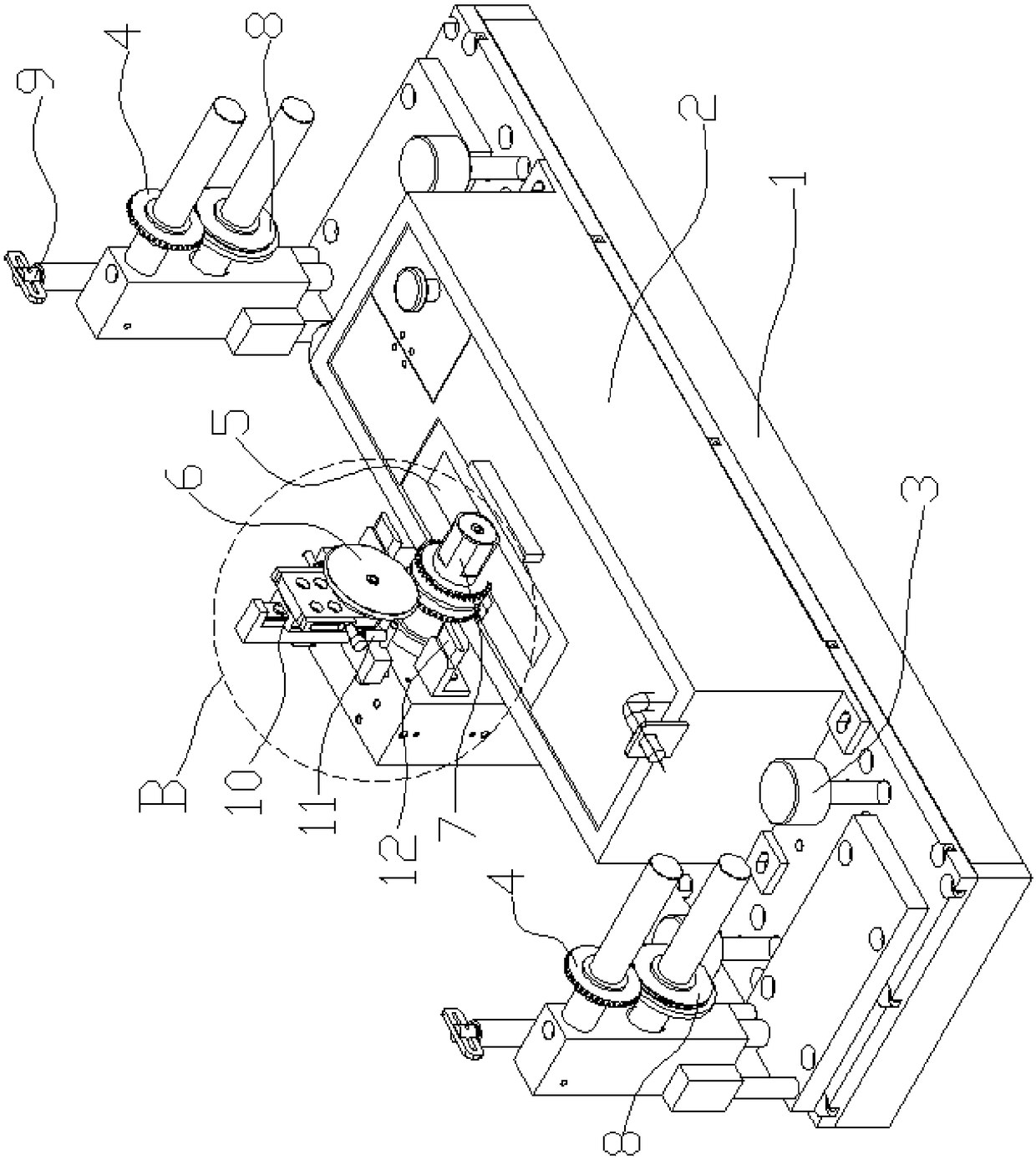

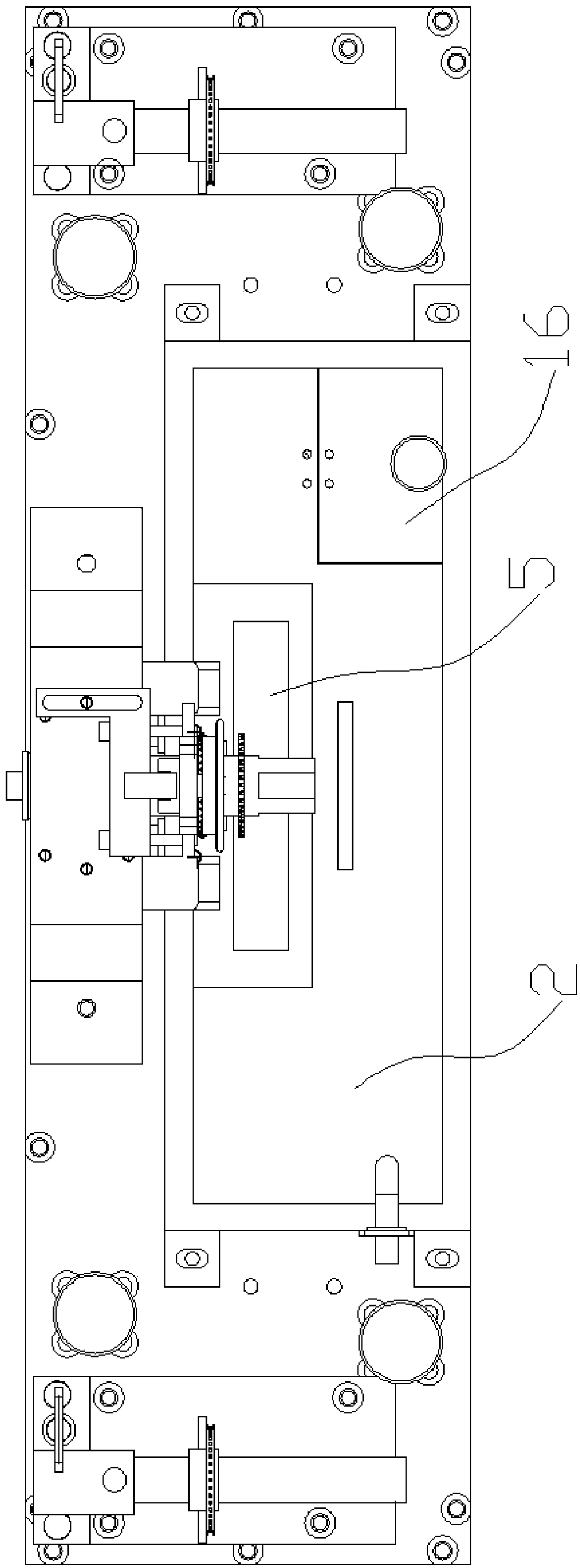

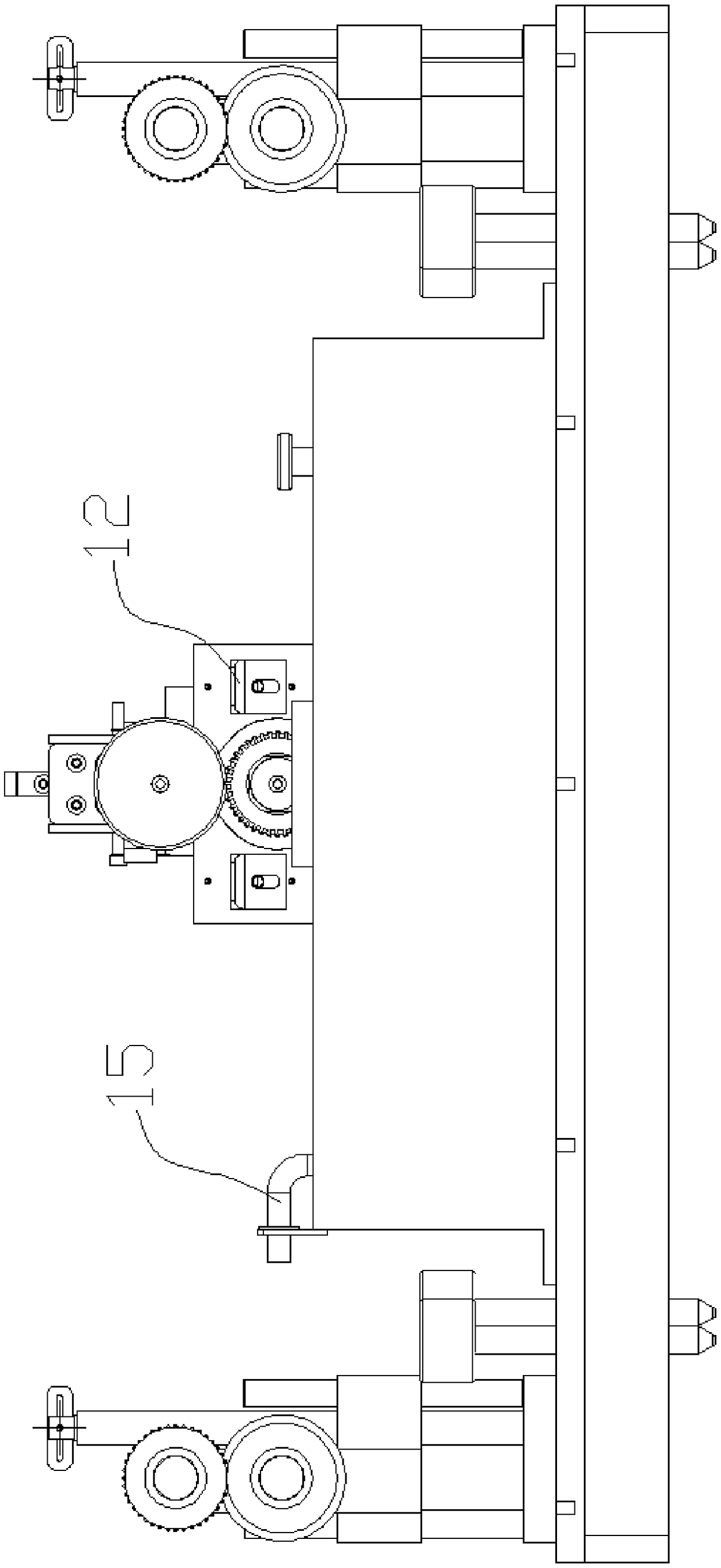

[0035] In order to achieve the purpose of the present invention, a kind of continuous wax spotting tank comprises: wax storage tank 5, is positioned at material belt 18 belows, is stored with liquid wax in the wax storage tank 5; The wax shaft 7 is in contact with the lower surface of the material belt 18, and the wax pointing shaft 7 is provided with radially protruding wax dipping teeth 19. With the rotation of the wax pointing shaft 7, the wax dipping teeth 19 will dip the liquid wax in the wax storage tank 5. Be attached on the material belt 18; Transmission limit mechanism, possesses feed wheel 4, lower support roller 8 of circumscribed up and down respectively, the own axis of feed wheel 4, lower support roller 8 is parallel with the self axis of waxing axle 7, at point Both sides of the wax shaft 7 are respectively provided with a feeding wheel 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com