Composite multilayer board for furniture and preparation method of composite multilayer board

A multi-layer board and furniture technology, applied in the field of furniture, can solve the problems of poor water resistance and fire resistance of adhesives, and achieve the effects of improving compatibility, water resistance and fire resistance, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

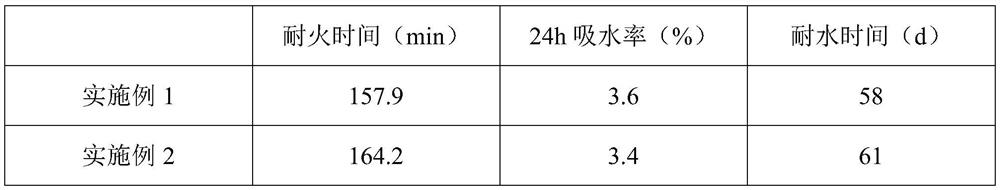

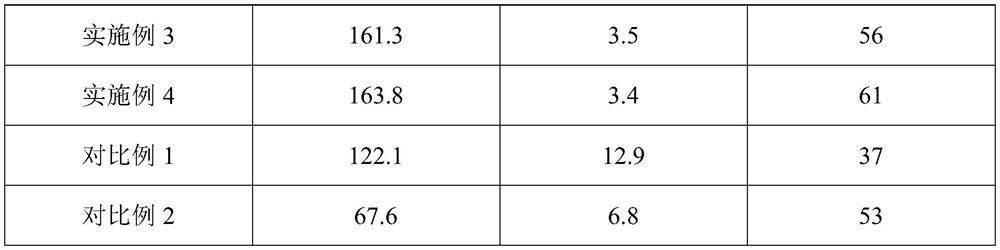

Examples

Embodiment 1

[0025] A preparation method for a composite multilayer board for furniture, comprising the following preparation steps:

[0026] (1) plank pretreatment: poplar plank is put into 10wt% sodium hydroxide solution and soaked for 8h, obtains pretreated plank;

[0027] (2) Preparation of composite adhesive: 80g silica modified konjac flour, 30g polyacrylamide modified montmorillonite, 8g polyvinyl alcohol, 4g magnesium oxide, 2g vinyltriethoxysilane, 2g paraffin Stir and mix the emulsion and 50g of water evenly to obtain a composite adhesive;

[0028] Wherein, the preparation method of silicon dioxide modified konjac flour is as follows: 5g nano silicon dioxide is added in the 500mL ethanol aqueous solution (the mass fraction of ethanol is 60%), disperse evenly, then add 20g konjac flour wherein, at 40 ℃ Stir evenly, then add 2g of silane coupling agent KH-550 to it, stir and react at 60°C for 8h, after the reaction is completed, wash, filter and dry the product to obtain silica-mo...

Embodiment 2

[0032] A preparation method for a composite multilayer board for furniture, comprising the following preparation steps:

[0033] (1) plank pretreatment: put poplar plank into 12wt% sodium hydroxide solution and soak for 10h to obtain pretreated plank;

[0034] (2) Preparation of composite adhesive: 100g silica modified konjac flour, 40g polyacrylamide modified montmorillonite, 12g polyvinyl alcohol, 5g magnesium oxide, 3g vinyltriethoxysilane, 4g paraffin Stir and mix the emulsion and 60g of water evenly to obtain a composite adhesive;

[0035] Wherein, the preparation method of silicon dioxide modified konjac flour is as follows: 8g nano silicon dioxide is joined in the 500mL ethanol aqueous solution (the mass fraction of ethanol is 60%), disperse evenly, then add 25g konjac flour wherein, at 40 ℃ Stir evenly under low pressure, then add 3g of silane coupling agent KH-550 to it, stir and react at 60°C for 8h, after the reaction is completed, wash, filter and dry the product ...

Embodiment 3

[0039] A preparation method for a composite multilayer board for furniture, comprising the following preparation steps:

[0040] (1) plank pretreatment: put poplar plank into 15wt% sodium hydroxide solution and soak for 8h to obtain pretreated plank;

[0041] (2) Preparation of composite adhesive: 120g silica modified konjac flour, 50g polyacrylamide modified montmorillonite, 10g polyvinyl alcohol, 6g magnesium oxide, 3g vinyltriethoxysilane, 5g paraffin Stir and mix the emulsion and 50g of water evenly to obtain a composite adhesive;

[0042] Wherein, the preparation method of silicon dioxide modified konjac powder is as follows: 10g nanometer silicon dioxide is joined in the 500mL ethanol aqueous solution (the mass fraction of ethanol is 60%), disperses uniformly, then adds 30g konjac powder wherein, at 40 ℃ Stir evenly at high temperature, then add 4g of silane coupling agent KH-550 to it, stir and react at 60°C for 8h, after the reaction is completed, wash, filter and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com