Method for treating common pollutants in environment through combination of biochar and micro-plastics

A technology of microplastics and biochar, applied in the direction of sustainable biological treatment, restoration of polluted soil, chemical instruments and methods, etc., can solve the problems of interaction that need further research, so as to avoid secondary microplastic pollution, operation Convenience and good compound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

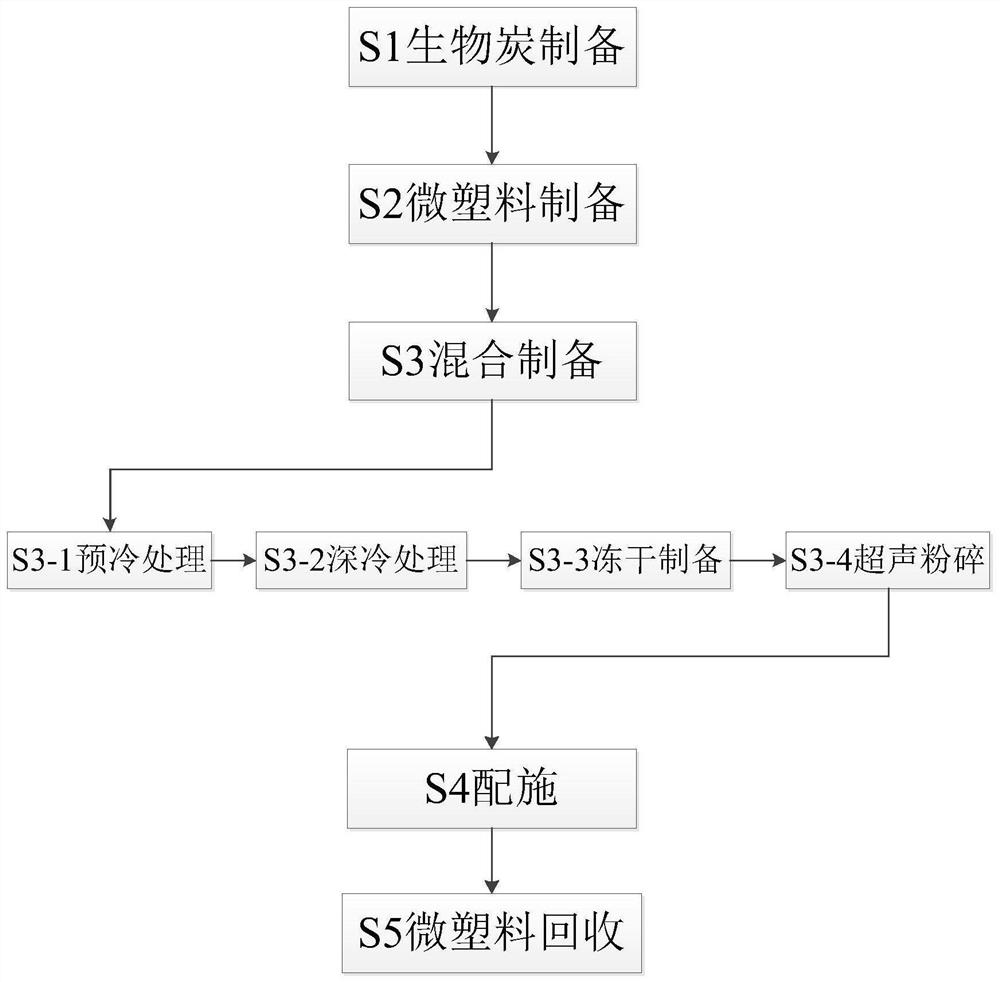

[0031] A method for treating common pollutants in the environment with biochar combined with microplastics, comprising the following steps:

[0032] S1. Preparation of biochar: take wheat straw and expose it to the sun for 2 days, wash it with distilled water for 3 times, and then dry it in an oven at 78°C for 7 hours. Wheat straw was placed in a tube furnace and heated to 400°C at a heating rate of 22°C / min, kept for carbonization for 1 hour, then heated to 500°C at a heating rate of 10°C / min, kept for carbonization for 2.5 hours, cooled to room temperature, and then taken out. Grinding the carbonized wheat straw in a grinder to a wheat straw biochar powder with an average particle size of 0.3 mm;

[0033] S2. Preparation of microplastics: take polyethylene microplastics and pulverize them in a pulverizer, and sieve the pulverized microplastics through a 70-mesh sieve to obtain microplastic powders;

[0034]S3, mixing preparation:

[0035] S3-1. Pre-cooling treatment: Mix t...

Embodiment 2

[0042] The difference between this example and Example 1 lies in that the parameters of the biochar preparation process in step S1 are different.

[0043] S1. Preparation of biochar: take wheat straw and expose it to the sun for 2 days, wash it with distilled water for 3 times, and then dry it in an oven at 75°C for 6 hours. Wheat straw was placed in a tube furnace and heated to 400°C at a heating rate of 20°C / min, kept for carbonization for 1 hour, then heated to 500°C at a heating rate of 10°C / min, kept for carbonization for 2 hours, cooled to room temperature, and taken out. The carbonized wheat straw was ground in a grinder to a wheat straw biochar powder with an average particle size of 0.15 mm.

Embodiment 3

[0045] The difference between this embodiment and the embodiment lies in that the parameters of the biochar preparation process in step S1 are different.

[0046] S1. Preparation of biochar: take wheat straw and expose it to the sun for 2 days, rinse it with distilled water for 3 times, and then dry it in an oven at 80°C for 8 hours. After drying, crush the wheat straw in a pulverizer. Wheat straw was placed in a tube furnace and heated to 400°C at a heating rate of 25°C / min, kept for carbonization for 1 hour, then heated to 500°C at a heating rate of 10°C / min, kept for carbonization for 3 hours, cooled to room temperature, and taken out. The carbonized wheat straw was ground in a grinder to a wheat straw biochar powder with an average particle size of 0.45 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com